Thermoelectric conversion integrated reactor with turbine

A thermoelectric conversion and reactor technology, applied in thermal reactors, overall reactors, non-uniform reactors, etc., can solve problems such as low energy conversion efficiency, poor anti-radiation ability, complex mechanical structure, etc., and achieve high passive safety performance, The effect of high power density and high safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

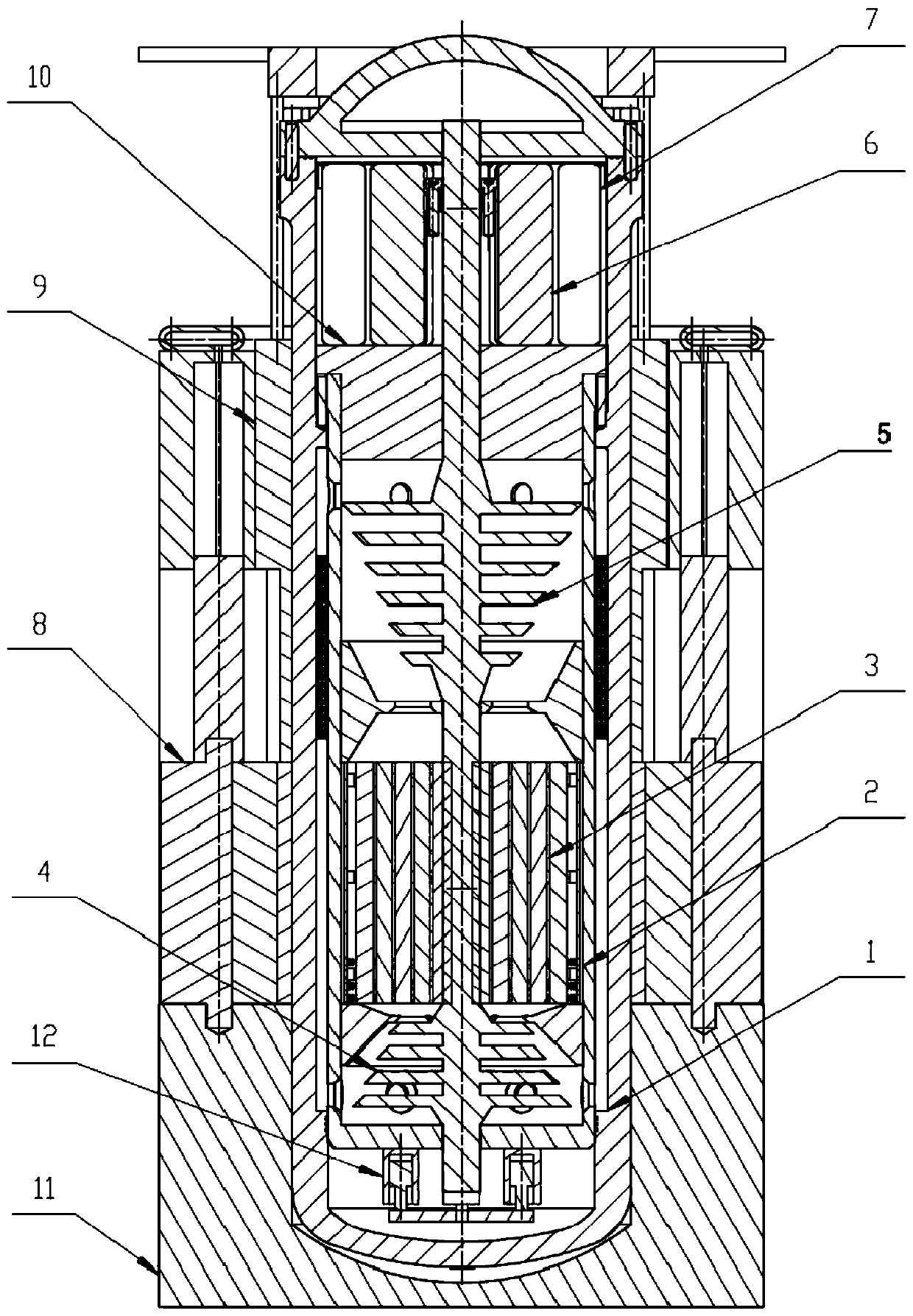

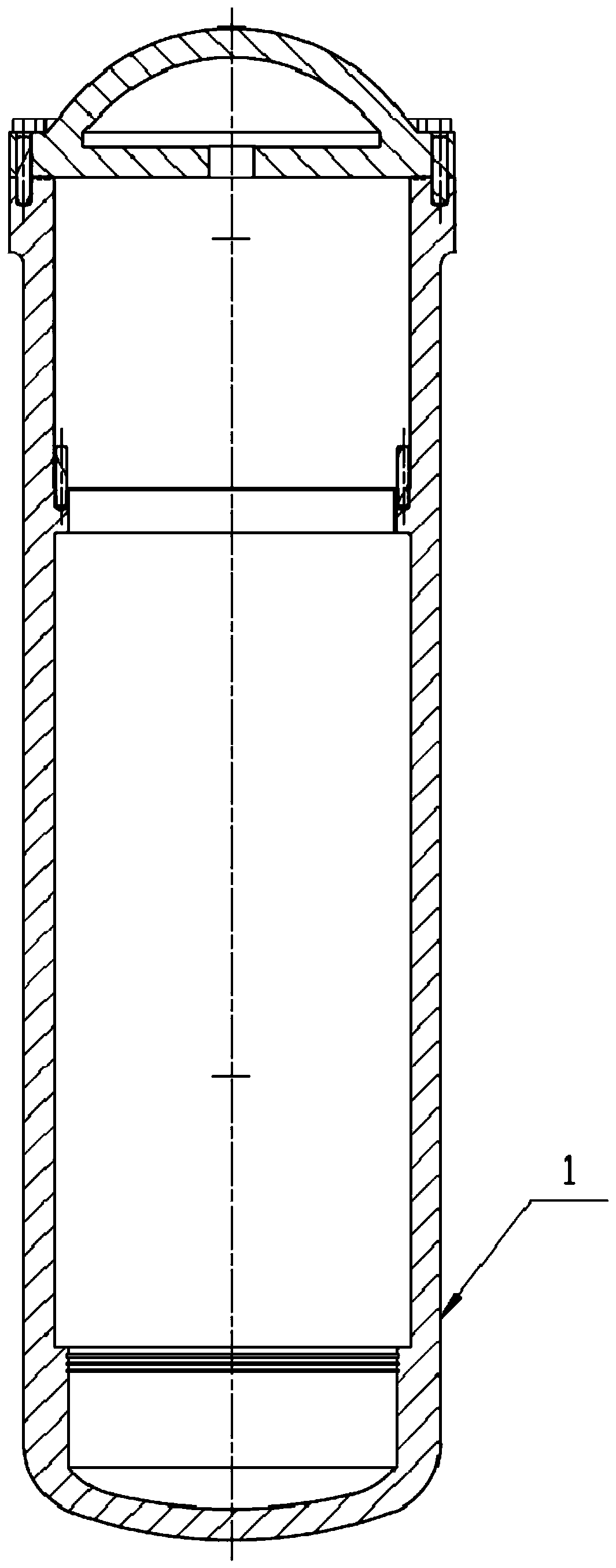

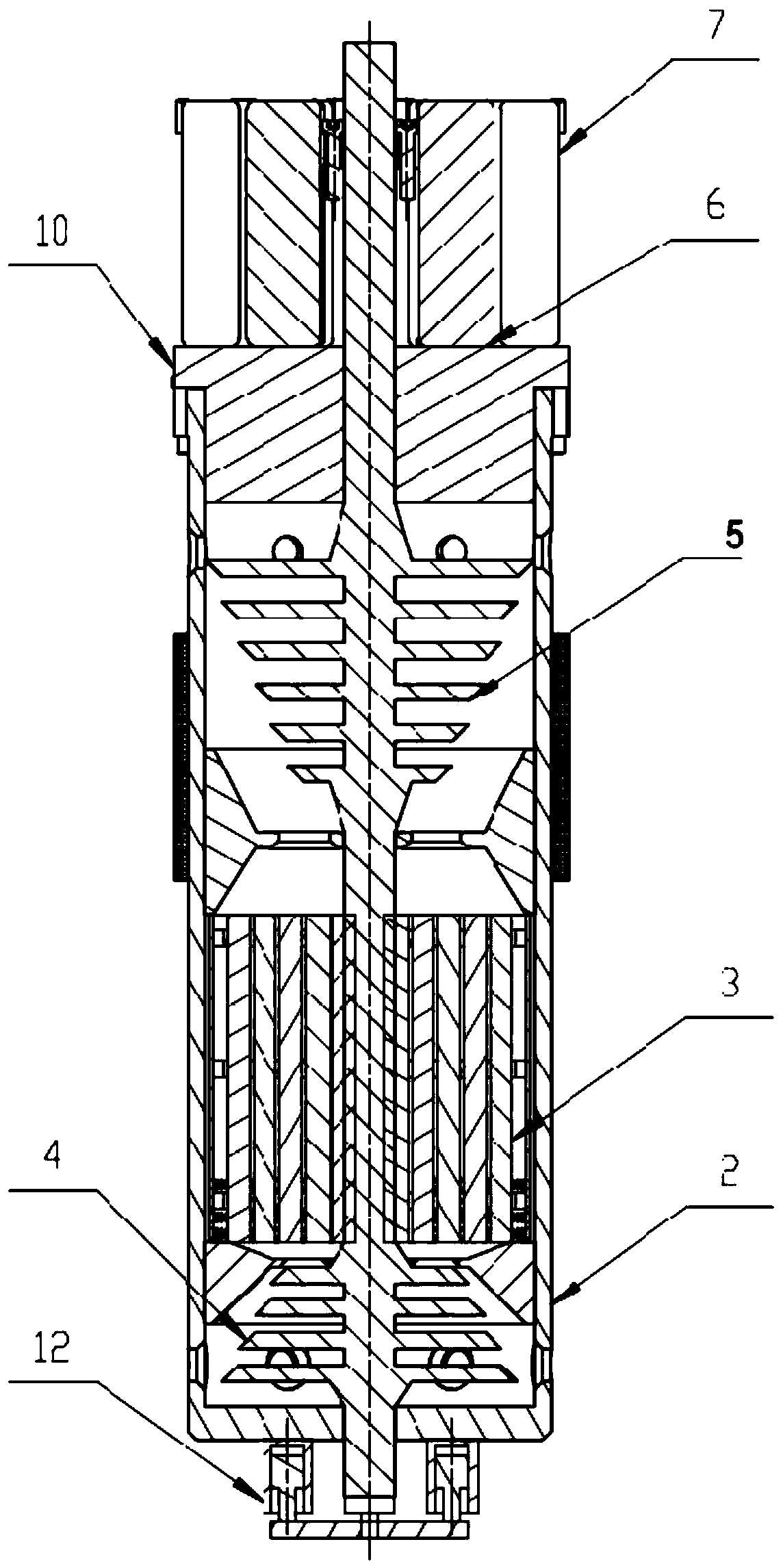

[0052] (1) The main body of the reactor is a nearly cylindrical pressure vessel, the outer diameter of the pressure vessel shroud is 280mm, the height is 920mm, the wall thickness of the pressure vessel cylinder is 20mm, the nominal diameter of the main bolt is 10mm, and the number is 24; the reactor core, energy conversion structure, power generation The machine and circulating medium are all arranged in the pressure vessel; the reflective layer structure with a drum for controlling the reactivity of the core is arranged outside the pressure vessel.

[0053] (2) The lower part of the pressure vessel is equipped with a shroud for internal components, which divides the space of the lower part of the pressure vessel into inner and outer areas; the outer diameter of the inner part of the shroud is 220mm, the height is 640mm, the wall thickness is 10mm, and the bottom of the shroud is 20mm thick bottom plate.

[0054] (3) The uranium nitride fuel elements with a diameter of 14mm a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com