Resistive memory and making method thereof

A technology of resistive memory and manufacturing method, applied in the direction of electrical components, etc., can solve problems such as inability to provide low-power solutions, unfavorable low-voltage operation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

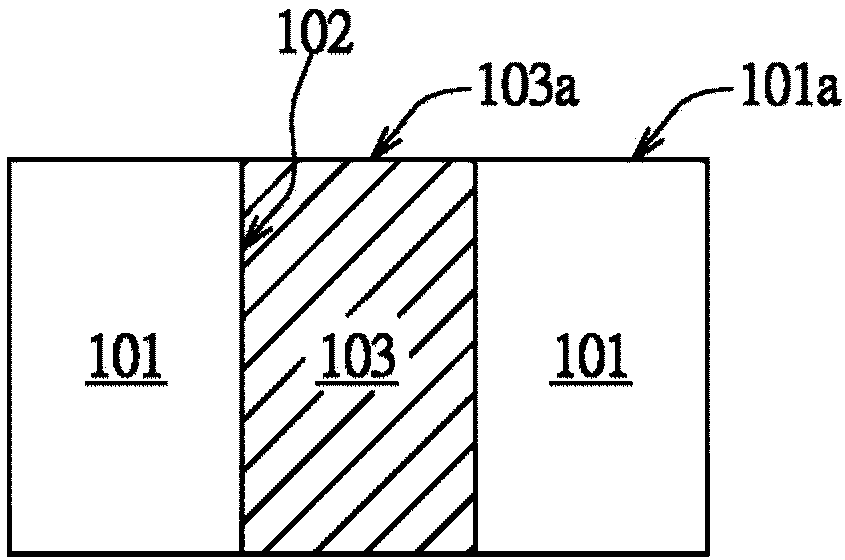

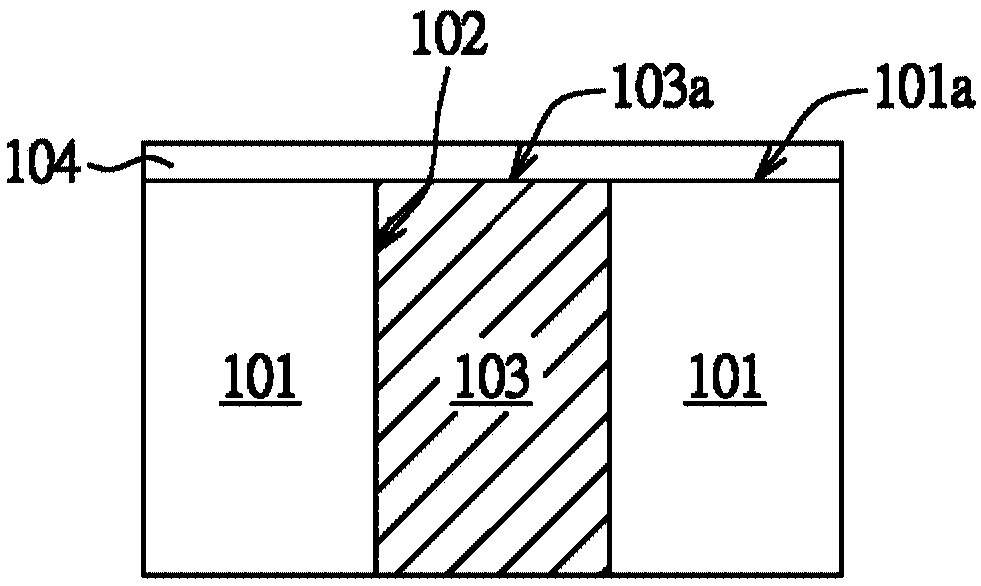

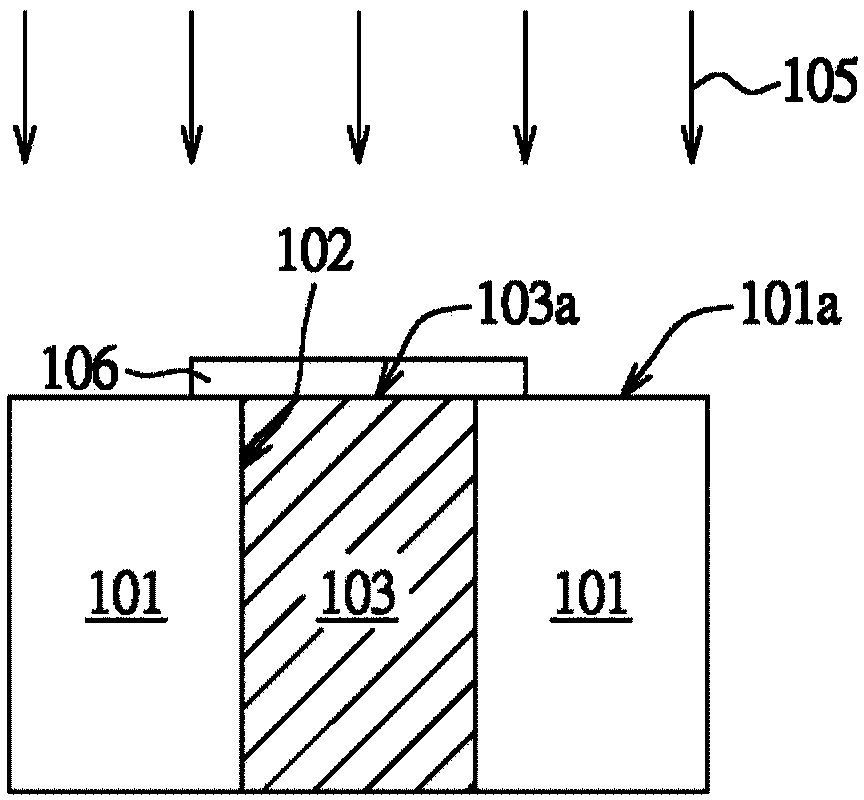

[0040] This description provides a resistive memory element and its manufacturing method, which can reduce the formation voltage of the memory element and increase the bit density of the resistive memory element. In order to make the above-mentioned embodiment and other objects, features and advantages of this specification more comprehensible, a memory device and its manufacturing method are specifically cited as a preferred embodiment below, and are described in detail with the accompanying drawings.

[0041] However, it must be noted that these specific implementation cases and methods are not intended to limit the present invention. The invention can still be implemented with other features, elements, methods and parameters. The proposal of the preferred embodiment is only used to illustrate the technical characteristics of the present invention, and is not intended to limit the patent scope of the present invention. Those skilled in the art will be able to make equivalen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com