Oil-in-water emulsion composition

An emulsified composition, oil-in-water type technology, applied in cosmetic preparations, pharmaceutical formulas, cosmetic preparations and other directions, can solve the problems of large particle size distribution width, unevenness, large particle size of oil droplets, etc. The effect of small distribution width and high stability over time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

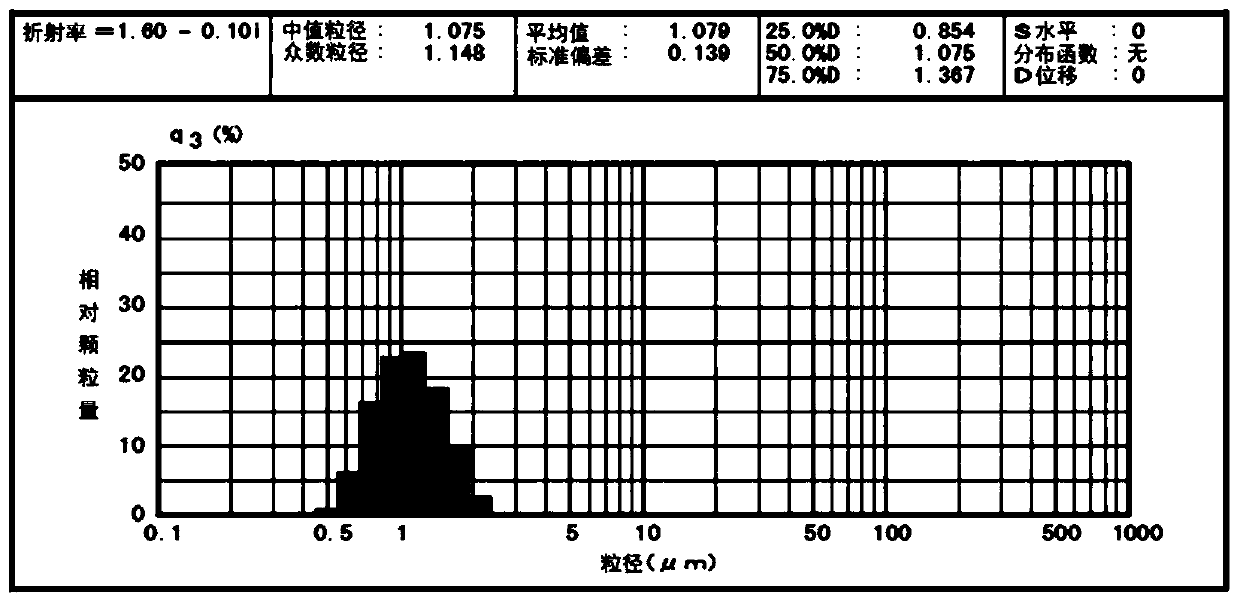

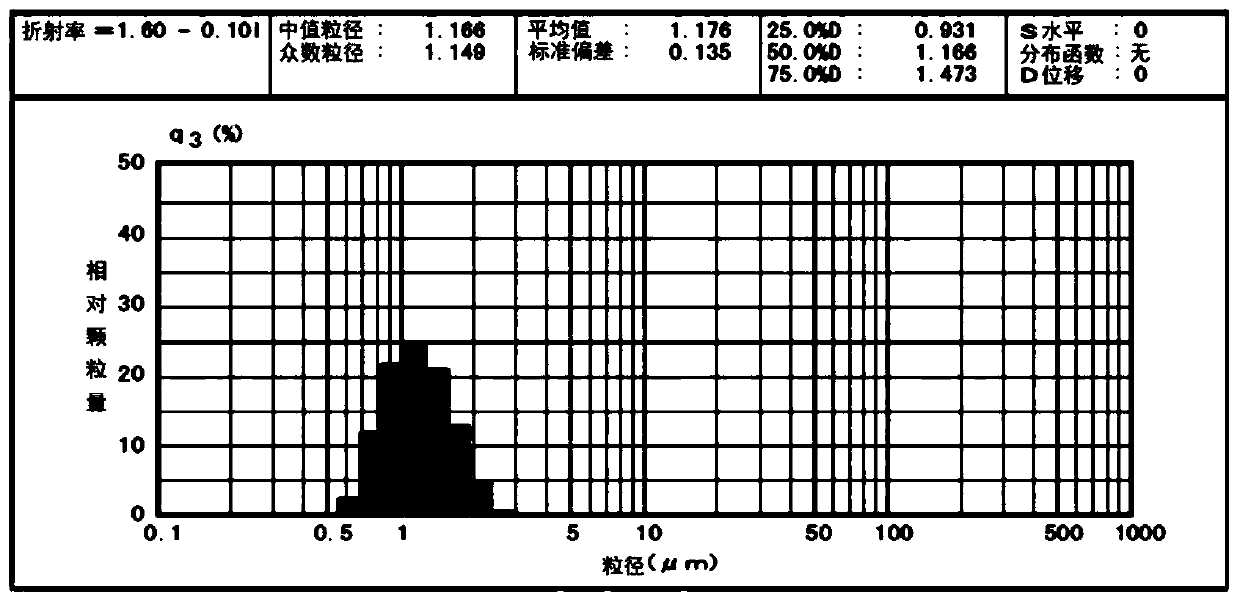

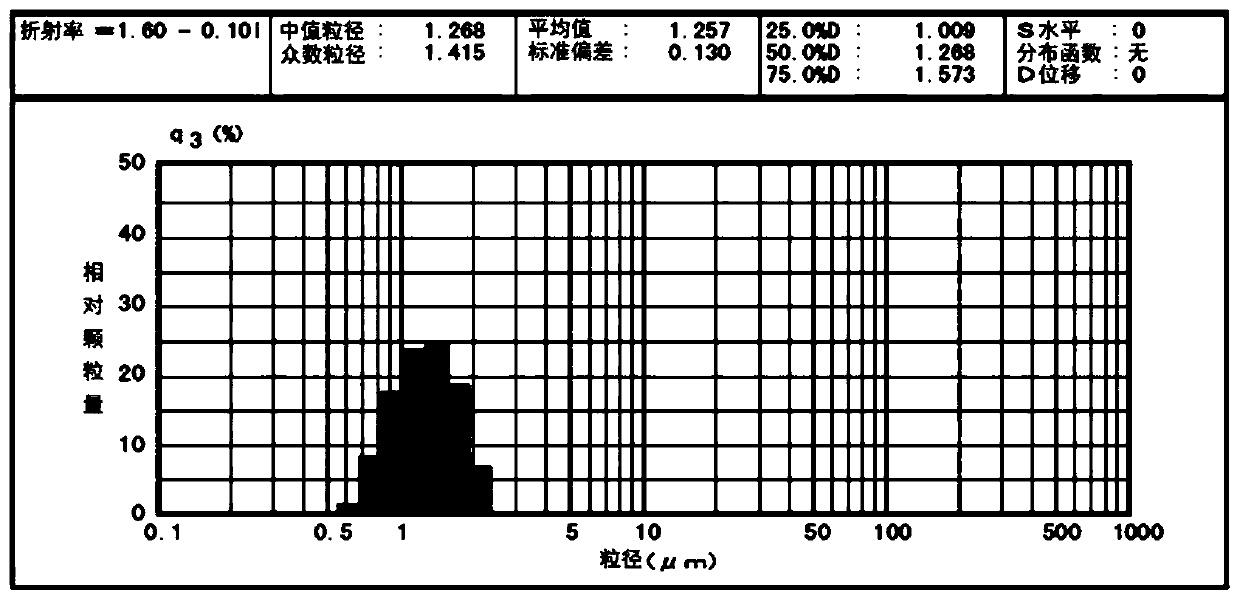

Image

Examples

Embodiment

[0092] The following examples are given to describe the present invention in more detail, but the present invention is not limited to the following examples.

manufacture example

[0093] Production example: Preparation of oil-in-water emulsified cosmetics

[0094] An oil phase and a water phase were respectively prepared by mixing each component by the compounding quantity shown to the Examples 1-10 of following Table 1 and Comparative Examples 1-4. Next, after heating the water phase and the oil phase to 80 to 85°C, the oil phase was added to the water phase, emulsified using a homomixer, and cooled to about 45°C. Next, neutralizers, alcohols, and additives were added and uniformly stirred in the compounding amounts shown in Examples 1 to 10 and Comparative Examples 1 to 4 in Table 1 below, thereby preparing Examples 1 to 10 and Comparative Examples 1 to 4 cosmetics.

[0095] After preparing the cosmetics of Examples 1 to 10 and Comparative Examples 1 to 4, it was confirmed visually that all the cosmetics were emulsified.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com