Method for improving stability of perovskite device

A technology of perovskite and stability, which is applied in the field of optoelectronic materials to achieve the effect of simple technology and improved stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

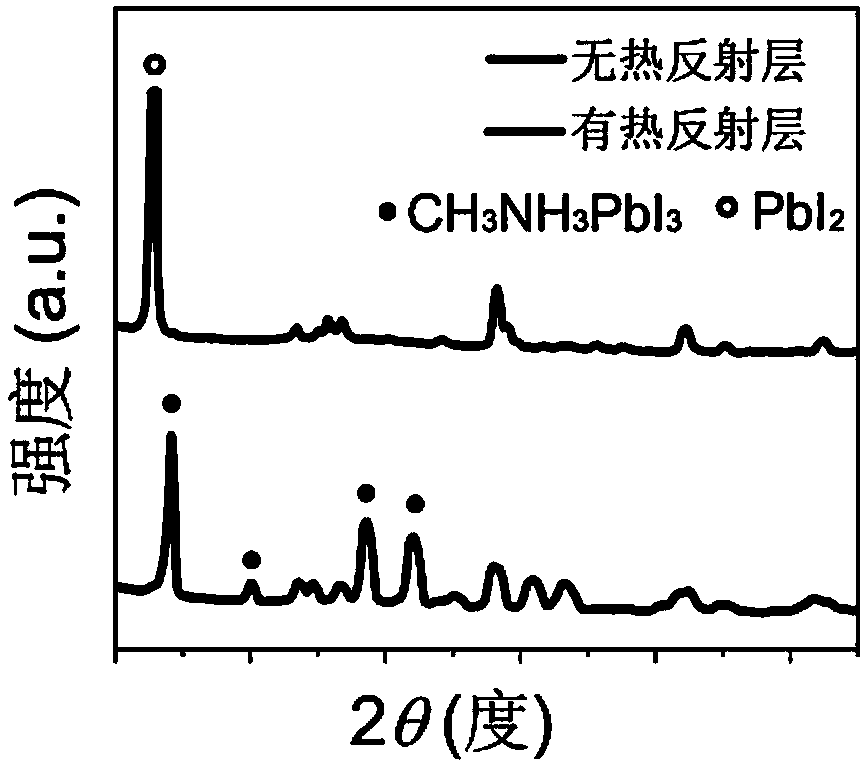

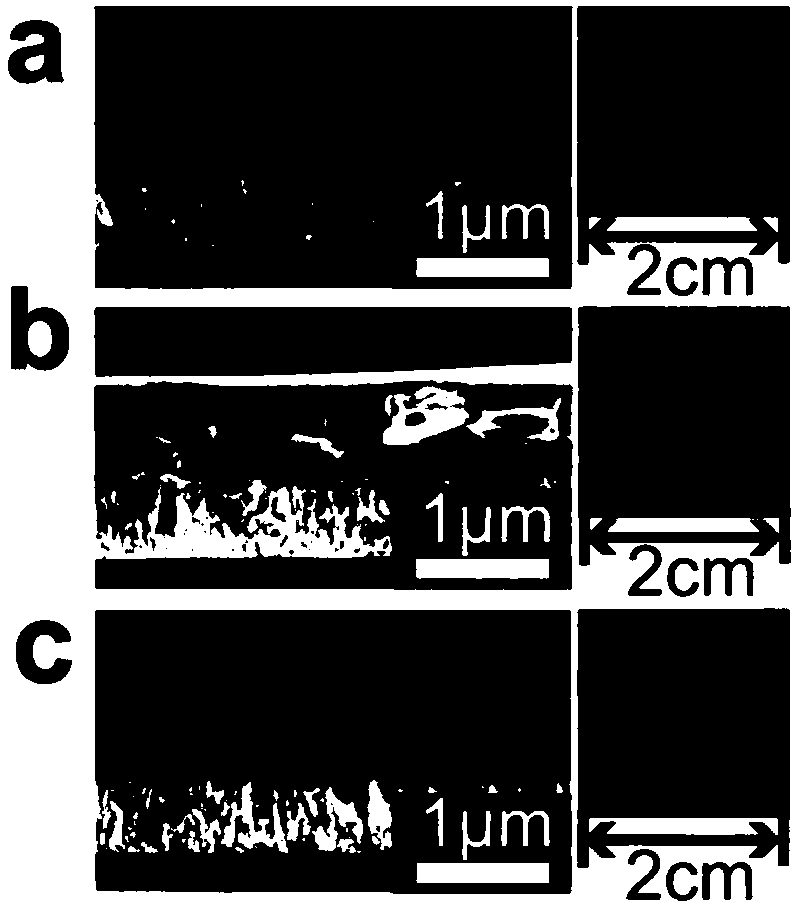

[0028] This embodiment relates to a method for improving the stability of an organic-inorganic hybrid perovskite device, comprising the following steps:

[0029] S1, preparation of dense zinc oxide substrate: use zinc oxide slurry, spin-coat on the surface of conductive FTO glass for 30s, dry at 120°C for 5min, repeat twice, and then anneal at 350°C for 15min.

[0030] S2, preparation of methylamine lead iodide perovskite film: first prepare the perovskite precursor solution, 461mg PbI 2 , 159mg of methylammonium iodide and 78mg of dimethyl sulfoxide were dissolved in 600mg of dimethylformamide, 60μL was spin-coated on the zinc oxide substrate for 30 seconds at a speed of 4000 rpm, and 0.5mL of diethyl ether was added in 10 seconds The clock drips slowly. The samples were left in the glove box for 24 hours until they turned brown.

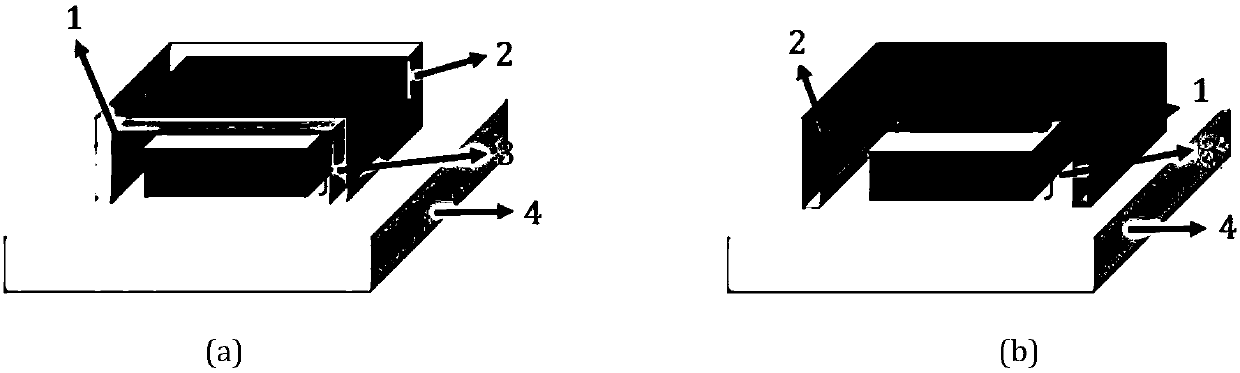

[0031] S3, Preparation of perovskite battery: Take the standard n-i-p structure, first grow Spiro-MeOTAD solid electrolyte on the grown perovski...

Embodiment 2

[0034] This embodiment relates to a method for improving the stability of an organic-inorganic hybrid perovskite device, comprising the following steps:

[0035] S1, preparation of dense zinc oxide substrate: use zinc oxide slurry, spin-coat on the surface of conductive FTO glass for 30s, dry at 120°C for 5min, repeat twice, and then anneal at 350°C for 15min.

[0036] S2, preparation of methylamine lead iodide perovskite film: first prepare the perovskite precursor solution, 461mg PbI 2 , 159mg of methylammonium iodide and 78mg of dimethyl sulfoxide were dissolved in 600mg of dimethylformamide, 60μL was spin-coated on the zinc oxide substrate for 30 seconds at a speed of 4000 rpm, and 0.5mL of diethyl ether was added in 10 seconds The clock drips slowly. The samples were left in the glove box for 24 hours until they turned brown.

[0037] S3, Preparation of perovskite battery: Take the standard n-i-p structure, first grow Spiro-MeOTAD solid electrolyte on the grown perovski...

Embodiment 3

[0040] This embodiment relates to a method for improving the stability of an organic-inorganic hybrid perovskite device, comprising the following steps:

[0041] S1, preparation of dense titanium oxide substrate: use titanium oxide slurry, spin-coat on the surface of conductive FTO glass for 30s, dry at 120°C for 5min, repeat twice, and then anneal at 350°C for 15min.

[0042] S2, preparation of formamidine lead iodide perovskite thin film: first prepare formamidine lead iodide precursor solution, take 60 μL and spin-coat it on the zinc oxide substrate for 30 seconds at a speed of 4000 rpm, and add 0.5 mL of diethyl ether in 10 seconds drip slowly. The samples were left in the glove box for 24 hours until they turned brown.

[0043]S3, Preparation of perovskite battery: Take the standard n-i-p structure, grow Spiro-MeOTAD solid electrolyte on the grown perovskite film, prepare Spiro-MeoTAD spin coating solution, mix 72.3mg Spiro-MeoTAD with 27μL 4-tert-butylpyridine 17 μL (c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com