Pesticide carrier based on plant sporopollen and application thereof

A plant spore and plant technology, applied in the field of pesticide carriers based on plant pollen, can solve problems such as no related research, and achieve broad prospects, diverse dosage forms, and good biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Example 1. Preparation of Lycopodium sporozoites (LCSC)

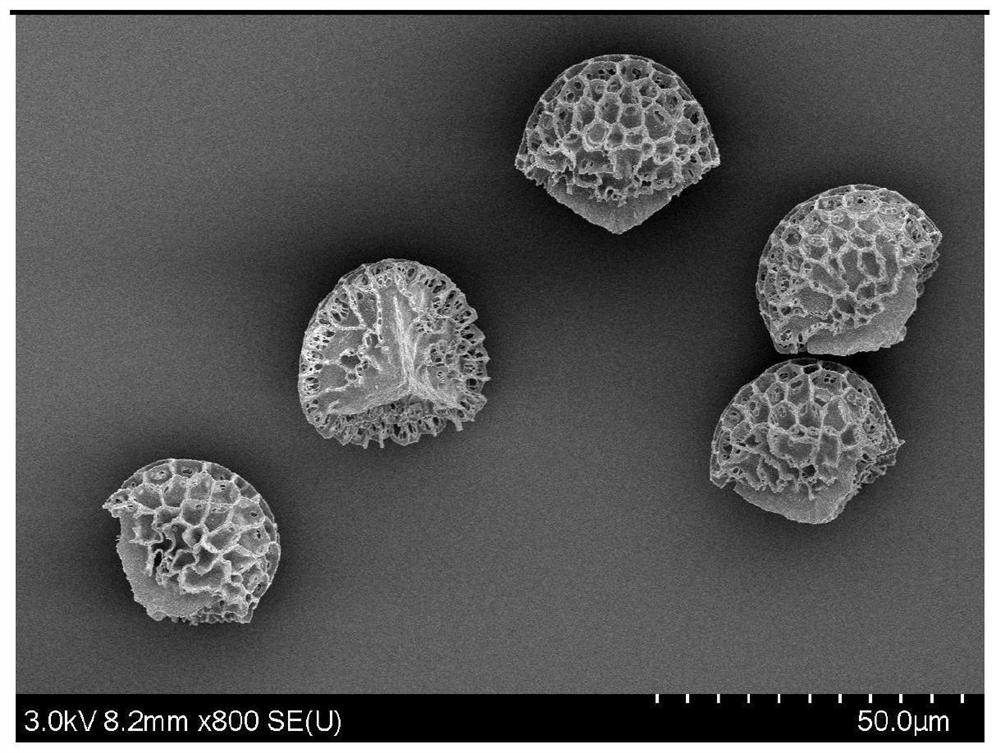

[0049]Weigh 5 g of lycopodium spore powder into 50 mL of acetone, stir magnetically for 4 hours at 50° C. (rotation speed is 500 rpm), and filter with suction to obtain delipidated lycopodium spore powder. Add 50 mL of 5M phosphoric acid solution to remove the genetic material in the inner cavity, stir magnetically for 4 hours at 80 °C (rotation speed is 500 rpm), filter with suction, wash with water 3 times, and dry the filter cake in a 60 °C oven to constant weight, that is, lycopodium spores are obtained. Pollen wall. Its appearance is as figure 1 shown.

Embodiment 2

[0050] Example 2. Preparation of fluazinam microcapsules (FLU@LCSC) based on lycopodium sporozoites

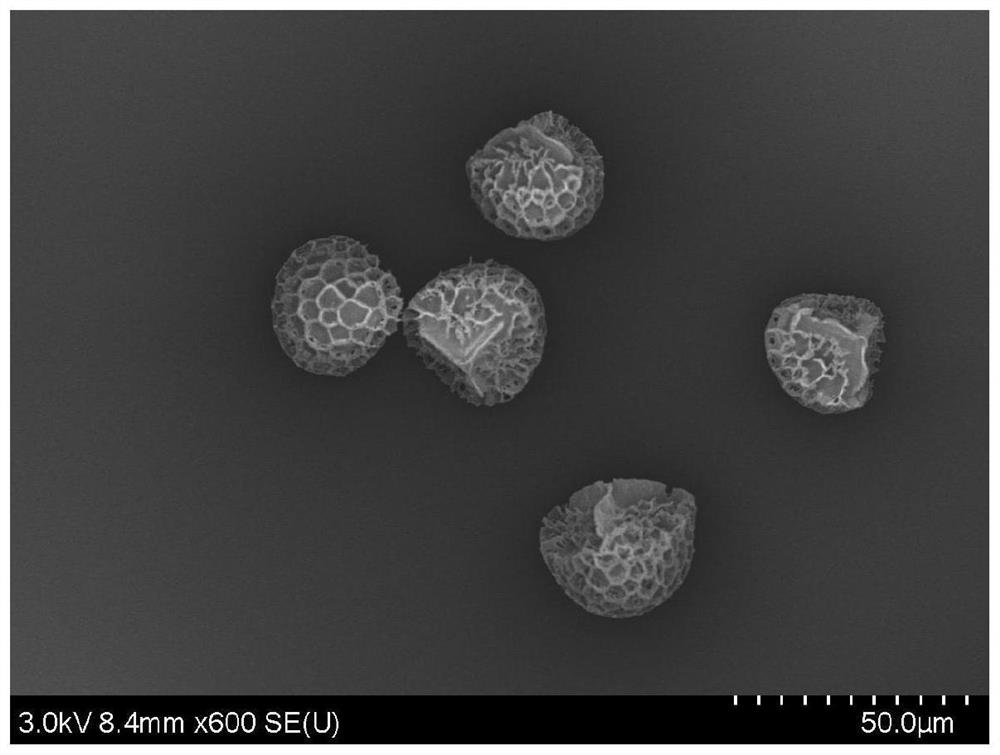

[0051] Weigh 10 g of the lycopodium spore powder material prepared in Example 1, add it to 50 mL of fluazimidine acetone solution (fluazimuth concentration is 0.2 g / mL), and magnetically stir at room temperature for 24 hours (rotation speed is 500 rpm). Then rotary-evaporated to dryness, transferred to a Buchner funnel for suction filtration, washed three times with acetone and twice with water. The filter cake was pre-frozen in a -40 ℃ refrigerator for 4 hours, and then freeze-dried for 12 hours to obtain fluazinam microcapsules (FLU@LCSC) based on lycopodium sporozoites. Its appearance is as figure 2 shown.

Embodiment 3

[0052] Example 3. Preparation of fluazinam microcapsules (FLU@LC) based on natural lycopodium spores

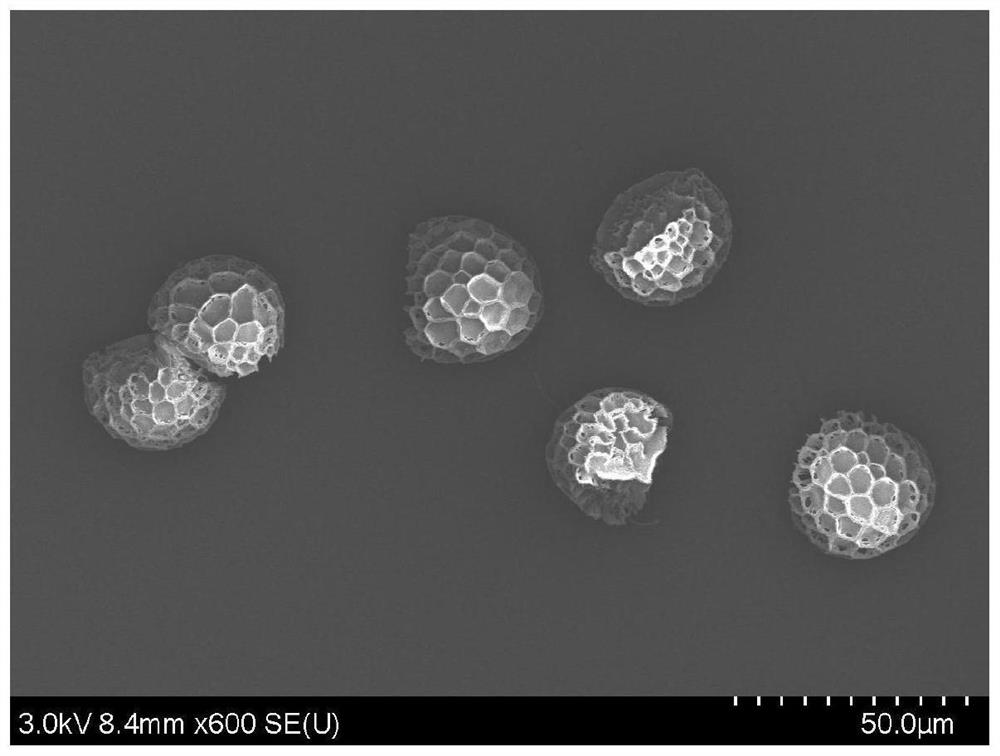

[0053] 10 g of natural Lycopodium spore powder was weighed and added to 50 mL of fluazinadine acetone solution (fluazimuth concentration was 0.2 g / mL), and the mixture was magnetically stirred at room temperature for 24 h (rotation speed was 500 rpm). Then rotary-evaporated to dryness, transferred to a Buchner funnel for suction filtration, washed three times with acetone and twice with water. The filter cake was pre-frozen in a -40°C refrigerator for 4 hours, and then freeze-dried for 12 hours to obtain fluazinam microcapsules (FLU@LC) based on natural lycopodium spores. Its appearance is as image 3 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com