A metal part manufacturing system and method for micro-casting laser shock texture

A laser shock and metal parts technology, applied in the field of metal parts manufacturing, can solve the problems of unavoidable internal defects of additively manufactured parts, and the uniformity of the structure affects the overall performance, so as to achieve uniform refinement of the microstructure, improve the mechanical properties of the structure, eliminate the Effects of Welding Residual Stresses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

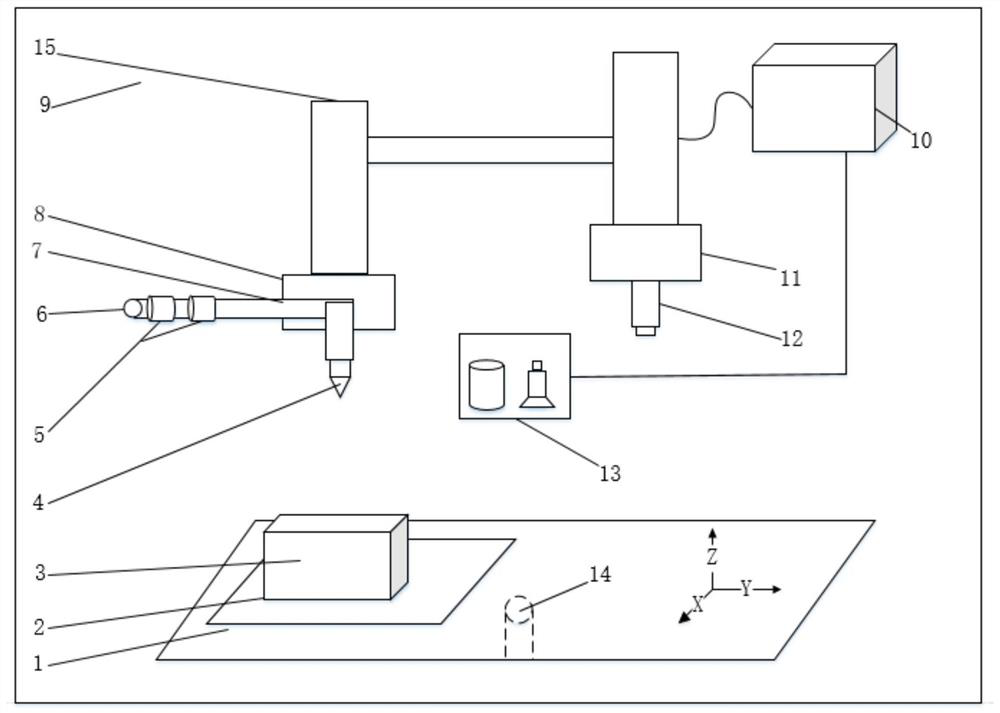

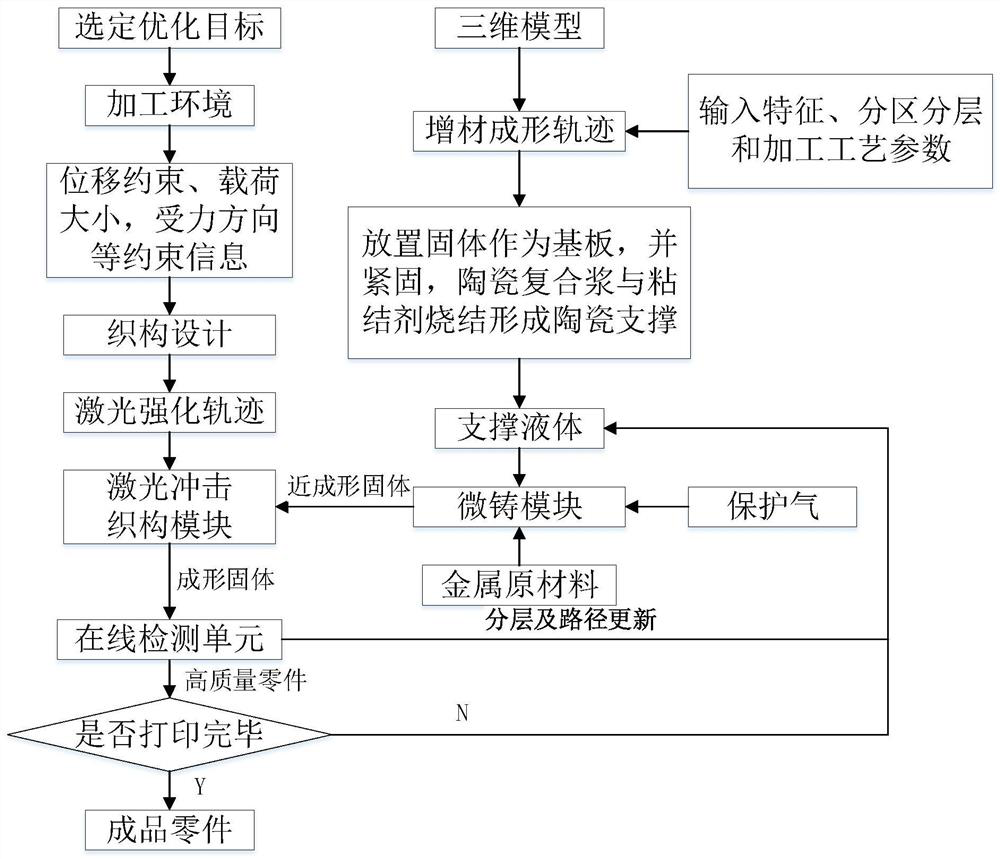

[0053] use as figure 1 In the system shown, the selected raw material is titanium alloy TC4-DT, the shape of the raw material is metal wire, and the supply method is wire-feeding, which specifically includes the following steps:

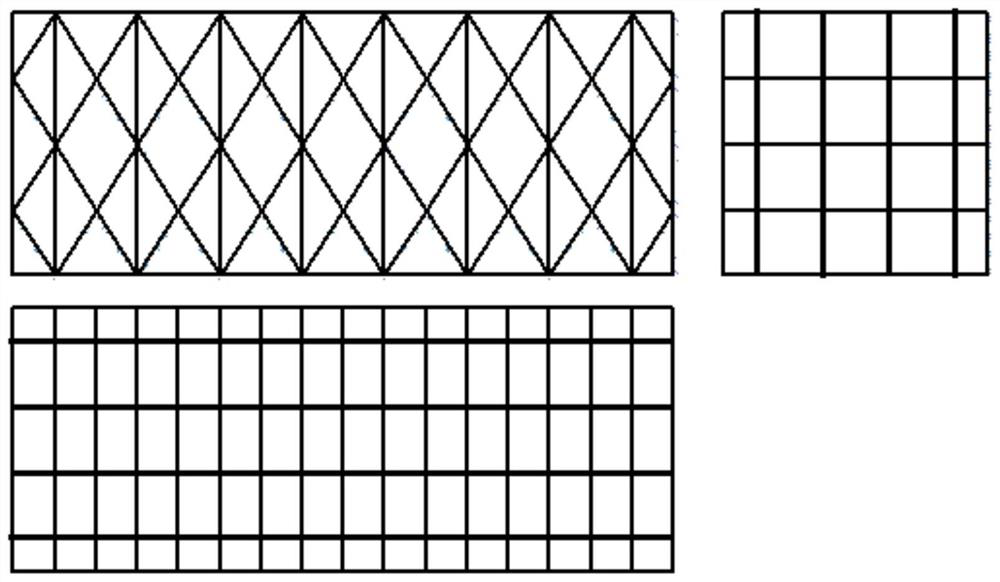

[0054] S1: Select the parameters such as the tissue performance and structural stiffness of the part as the optimization target, and apply the constraint information such as displacement constraints, load magnitude, and force direction according to the specific use environment, and design the overall texture structure, and the texture parts are meshed structure, such as image 3 As shown in , including the edge of the part and the internal network structure, the part shown by the black thick line is the texture part, and the laser shock texture strengthening track is preset;

[0055] S2: Through the 3D CAD model and features, zoning and layering, and processing parameters of the metal part 3 to be formed, an additive forming trajectory suitable for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com