Die and forging method for large-scale machine gate type forging

A technology for large machines and forgings, applied in the field of forging, which can solve the problems affecting the weight reduction of aircraft parts, the large residual stress of forgings, and the increase in the weight of parts and so on.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

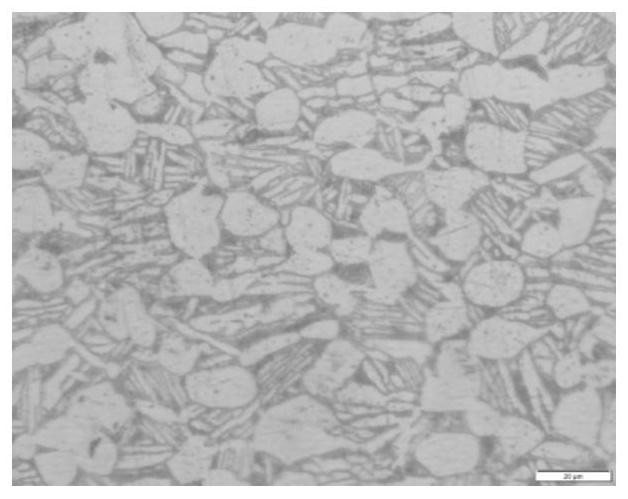

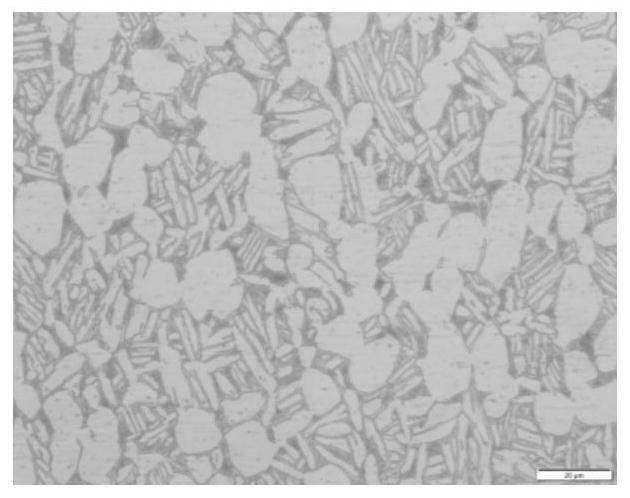

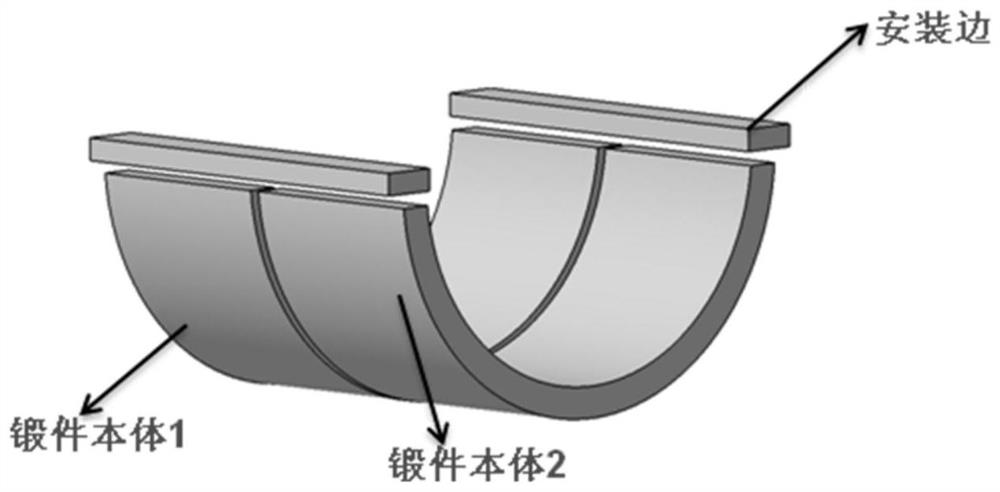

Embodiment 1

[0056] Taking the production of TA15 titanium alloy large-scale thin-walled casing die forgings as an example, first use a φ350mm TA15 titanium alloy bar, cut a 1143mm bar according to the process, and perform upsetting and shaping on the bar after blanking according to the specifications to prepare the blank . Then use a resistance furnace to preheat, and when the furnace temperature reaches Tβ-35°C, put the billet into the resistance furnace for heating, where Tβ is the phase transition point of the TA15 titanium alloy in the electric furnace. When the furnace temperature rises to Tβ-35°C again, it is kept for 280 minutes, and then the heated billet is quickly removed from the resistance furnace, and the billet is subjected to upsetting and shaping for 3 times on a 31.5MN fast forging machine, and finally the billet is processed into 1750×1045×275mm slab.

[0057] Process the surface of the slab, including the upper, lower, and side surfaces of the slab, so that the dimensi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com