An improved 9ni material suitable for large cross-section parts and its preparation method

An improved, large-section technology, applied in the field of forging, can solve the problems of poor structure and mechanical properties, and achieve the effects of good structure and mechanical properties, high tensile strength, and convenient engineering

Active Publication Date: 2020-07-10

INST OF METAL RESEARCH - CHINESE ACAD OF SCI

View PDF3 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] The object of the present invention is to provide a kind of 9Ni material that is applicable to large cross-section parts and preparation method thereof, in order to solve the problems such as poor structure and mechanical property that traditional 9Ni material shows on large cross-section parts

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

[0036] In the present embodiment, the chemical composition optimization experiment of the improved 9Ni material is as follows:

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Login to View More

Abstract

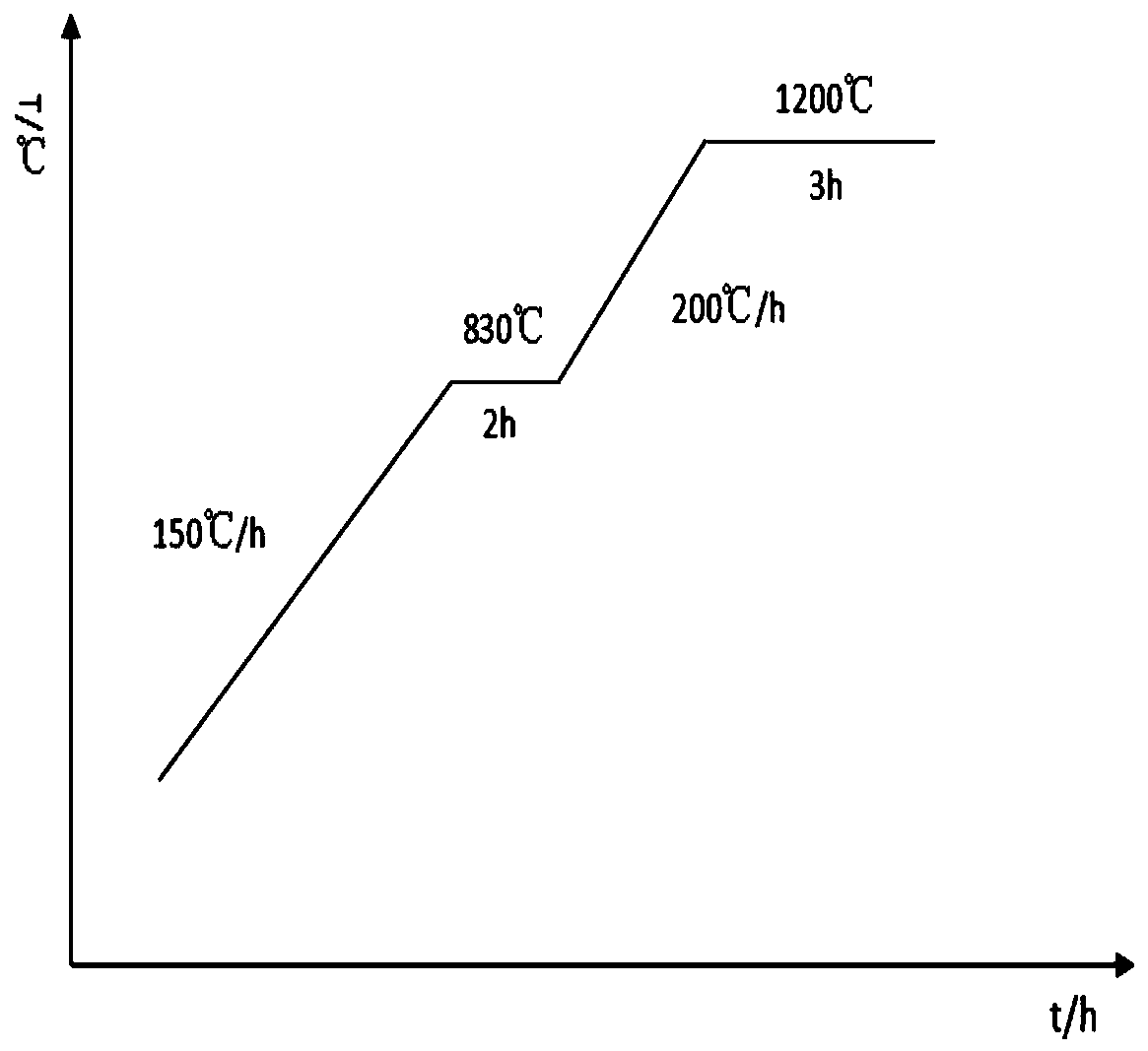

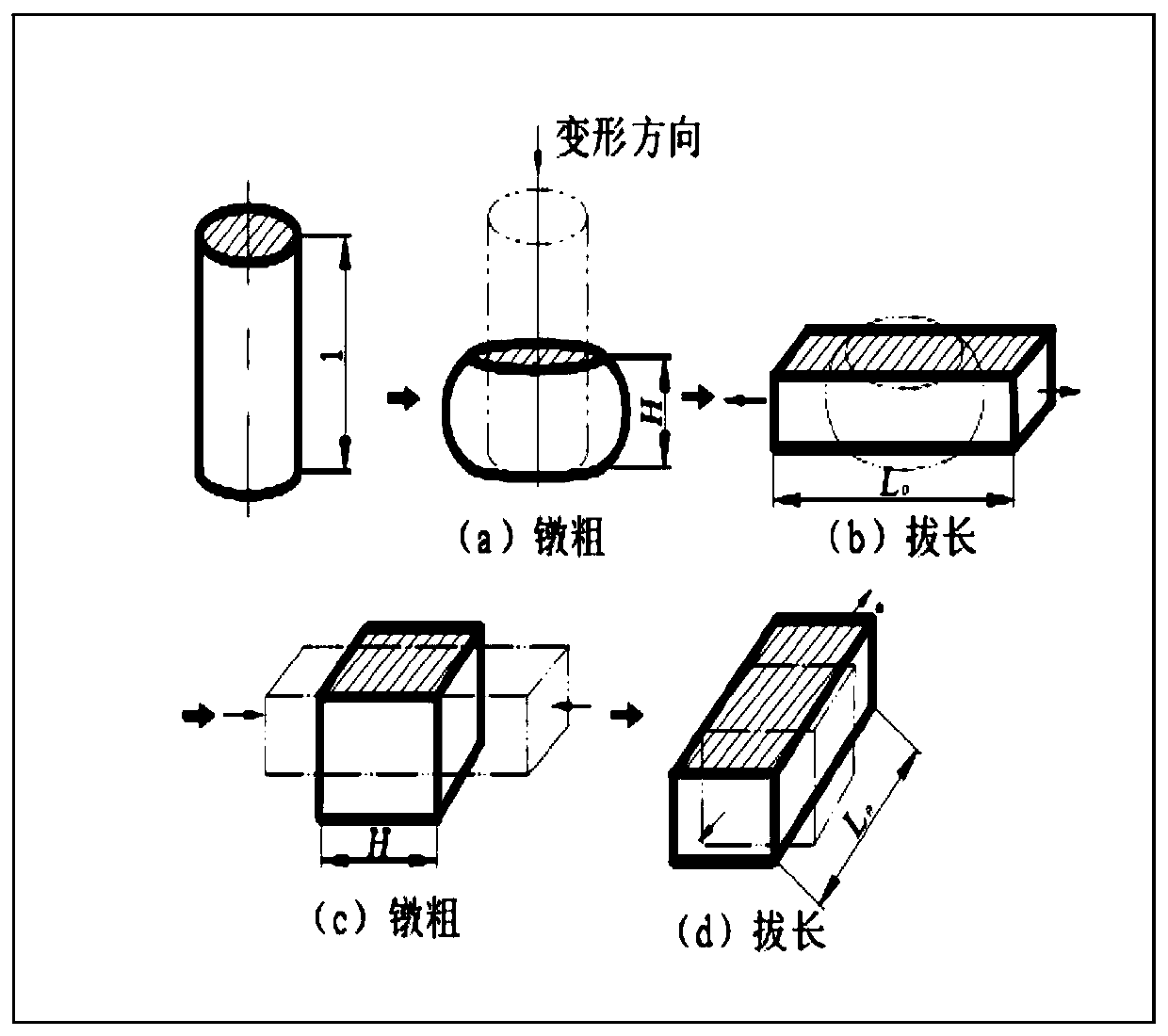

The invention belongs to the field of forging and particularly discloses an improved 9Ni material applicable to a large-section component and a preparation method thereof. By adopting the material andthe preparation method thereof, the problem that when a traditional 9Ni material is applied to the large-section component, the low-temperature toughness is poor is solved. According to the improved9Ni material and the preparation method thereof, in respect of improvement on the fracture toughness and hardenability, the contents of the elements including C, Mn, Si, Mo, Al, RE and the like in the9Ni material are optimized and controlled. Heat treatment simulation is performed on the quenching and tempering process of traditional 9Ni steel applied to a large forging, a heat treatment simulation furnace is utilized for performing physical simulation on the surface, the 1 / 2 R position and the center, as the samples, of the large forging, and mechanical property evaluation is performed to illuminate microstructure and property distribution laws from the surface to the center area of the 9Ni steel shaft large forging. The 9Ni material with ingredients optimized is observed and analyzed under a microscope and a scanning electron microscope, sample microstructures of the surface, 1 / 2 R position of the section and the center of the large forging are improved, and the mechanical propertyof the improved 9Ni material is greatly improved.

Description

technical field [0001] The invention belongs to the field of forging, and in particular relates to an improved 9Ni material suitable for large cross-section parts and a preparation method thereof. Background technique [0002] 9Ni steel is a steel for ultra-low temperature with a Ni content of about 9%. It has excellent low-temperature toughness, good weldability, and relatively low cost. It has become an important structural material for low-temperature equipment and containers at -196°C. Widely used in liquefied natural gas cryogenic storage tank plates, although it shows good mechanical properties in the above application cases, when the traditional 9Ni material is applied to large cross-section parts, its core will show problems such as poor low temperature toughness and uneven structure. And at present, there are very few applications in large cross-section parts in China. Therefore, the present invention is developed for the 9Ni material used in large-section componen...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C22C38/12C22C38/02C22C38/04C22C38/08C22C38/06C22C38/16C22C38/44C22C38/42C22C38/46C21D8/00C21D1/28

CPCC21D1/28C21D8/005C21D2211/002C21D2211/005C21D2211/008C22C38/005C22C38/02C22C38/04C22C38/06C22C38/08C22C38/12C22C38/16C22C38/42C22C38/44C22C38/46

Inventor 孙明月陈博伟包翠敏刘长胜徐斌刘生李殿中

Owner INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com