Indexable cutting blade for metal material cutting machining

A cutting and metal material technology, used in cutting inserts, metal processing equipment, tools for lathes, etc., can solve the problems of chip instability, increased chip curling, large cutting resistance, etc., to effectively control chip flow, reduce Cutting resistance, effect of controlling chip flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

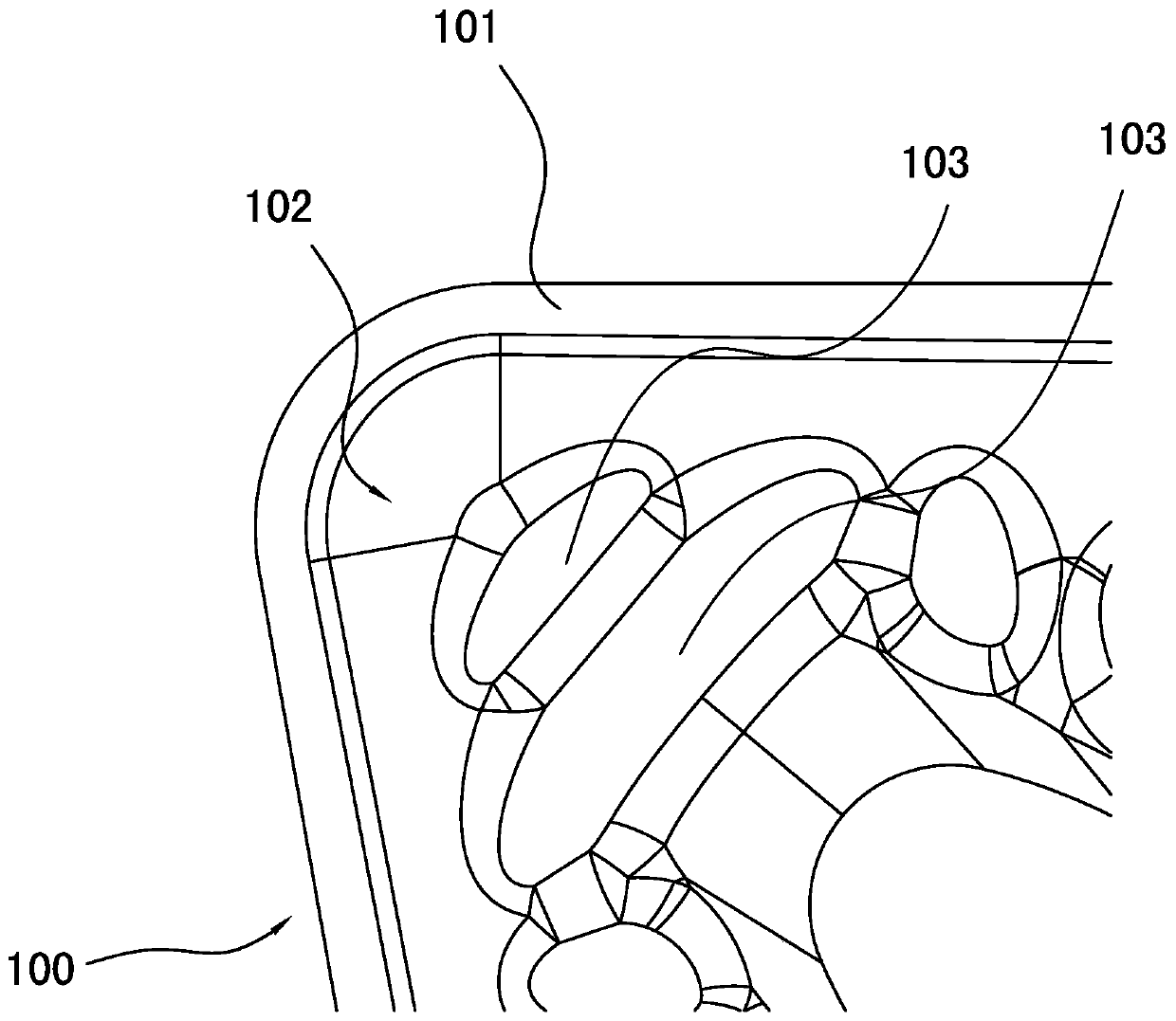

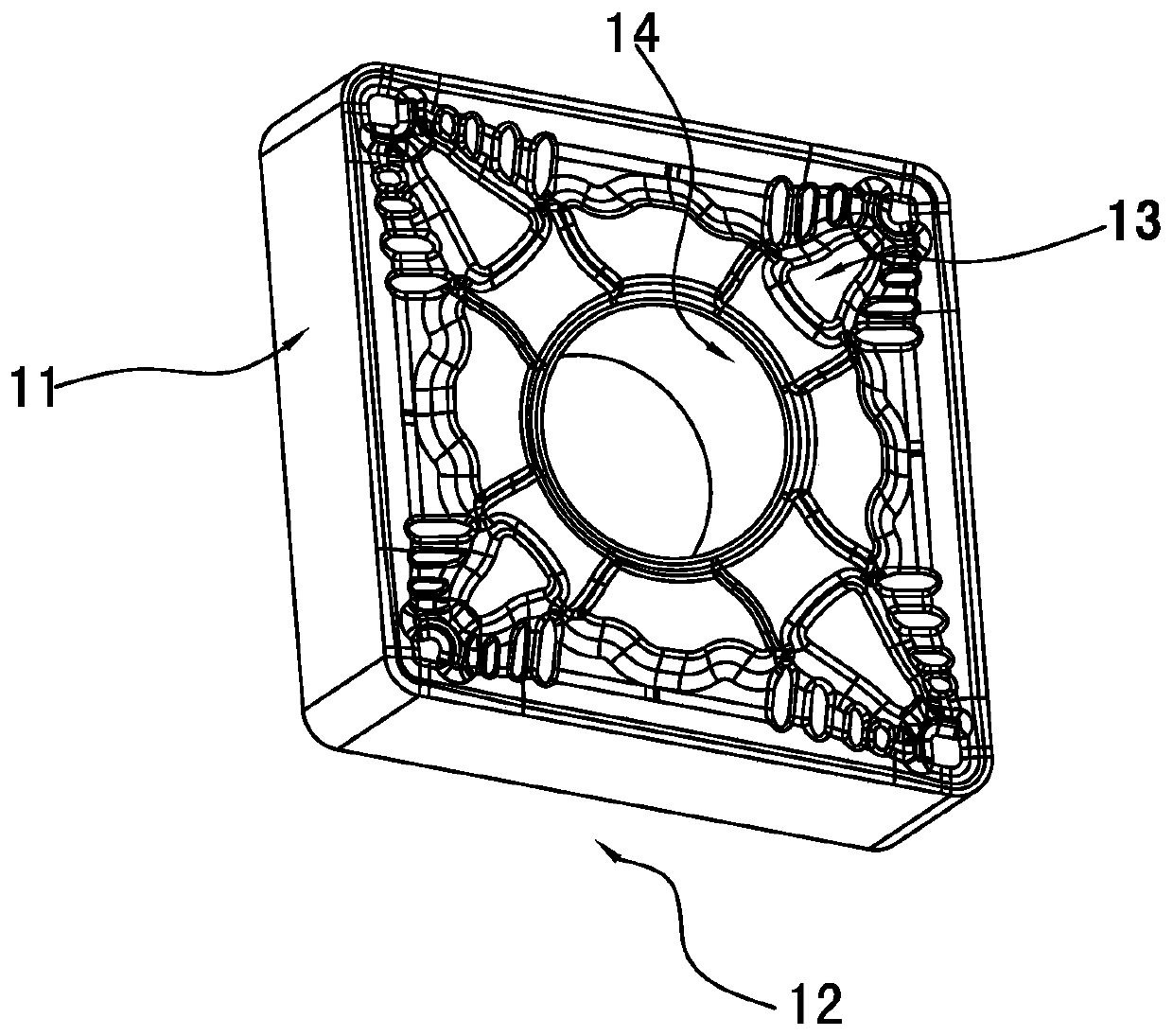

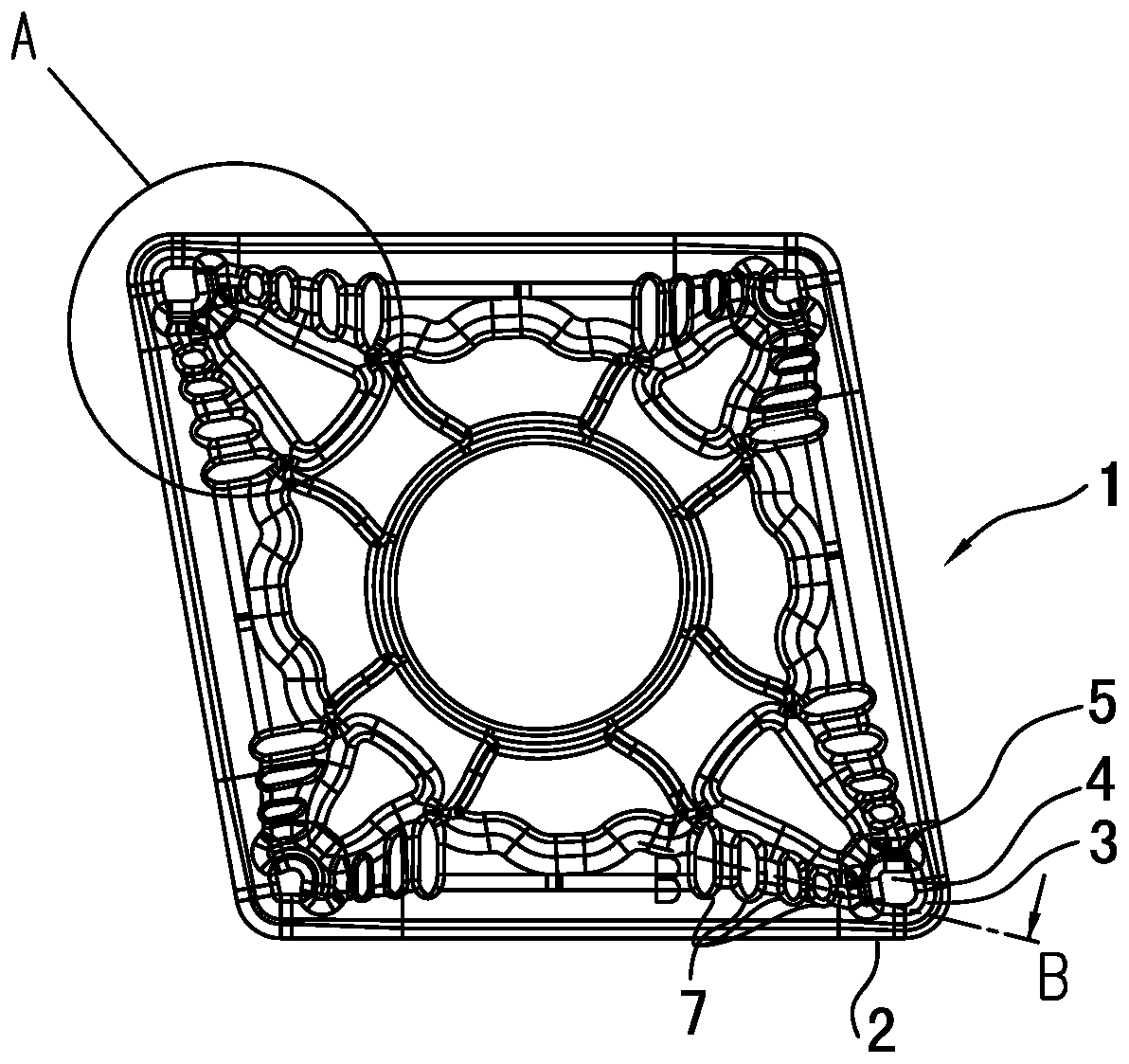

[0030] see Figure 2 to Figure 9 As shown, an indexable cutting insert for metal material cutting of the present invention includes a insert body 1, which is polygonal in shape, has an upper surface 11, a lower surface 12 and a side surface 13 connected between the upper and lower surfaces In the middle of the blade body 1, a through hole 14 is also provided to install the blade; the intersection of the upper and lower surfaces and the side forms the cutting edge 2; in the upper and lower surfaces, the cutting edge 2 Extending inwards is provided with a rake face, and the rake face is a bevel; Edge 2A and the side edge 2B that is arranged on both sides of the arc-shaped corner edge; On the rake face inside the tip of the tool, an overhanging boss 6 is formed at a distance from the cutting edge, and the boss 6 is directed toward the circle. A strip-shaped first raised portion 5 is connected to the direction of the arc-shaped corner edge; a concave portion 4 with a certain volu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com