Member grinding track generating method, device and equipment

A trajectory generation and component technology, used in grinding/polishing equipment, automatic grinding control devices, metal processing equipment, etc., can solve the problems of low adaptability and work efficiency, and achieve improved trajectory generation efficiency and high professional skills. , low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

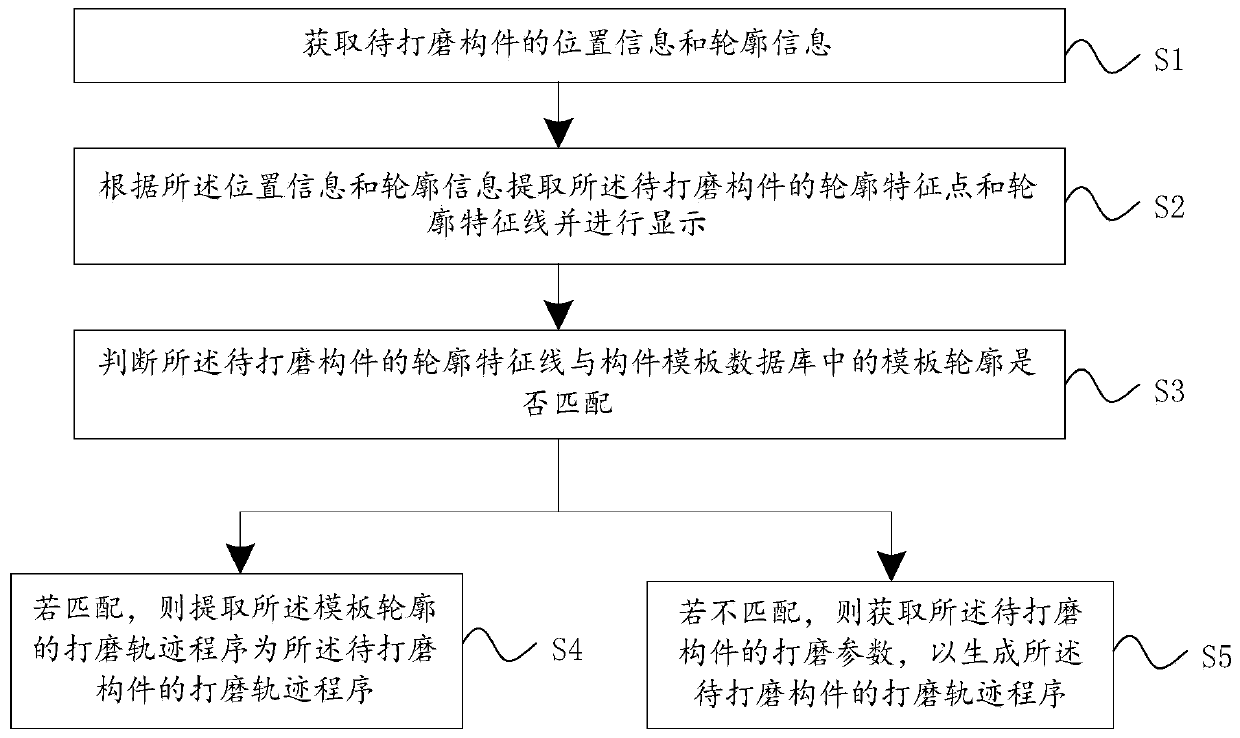

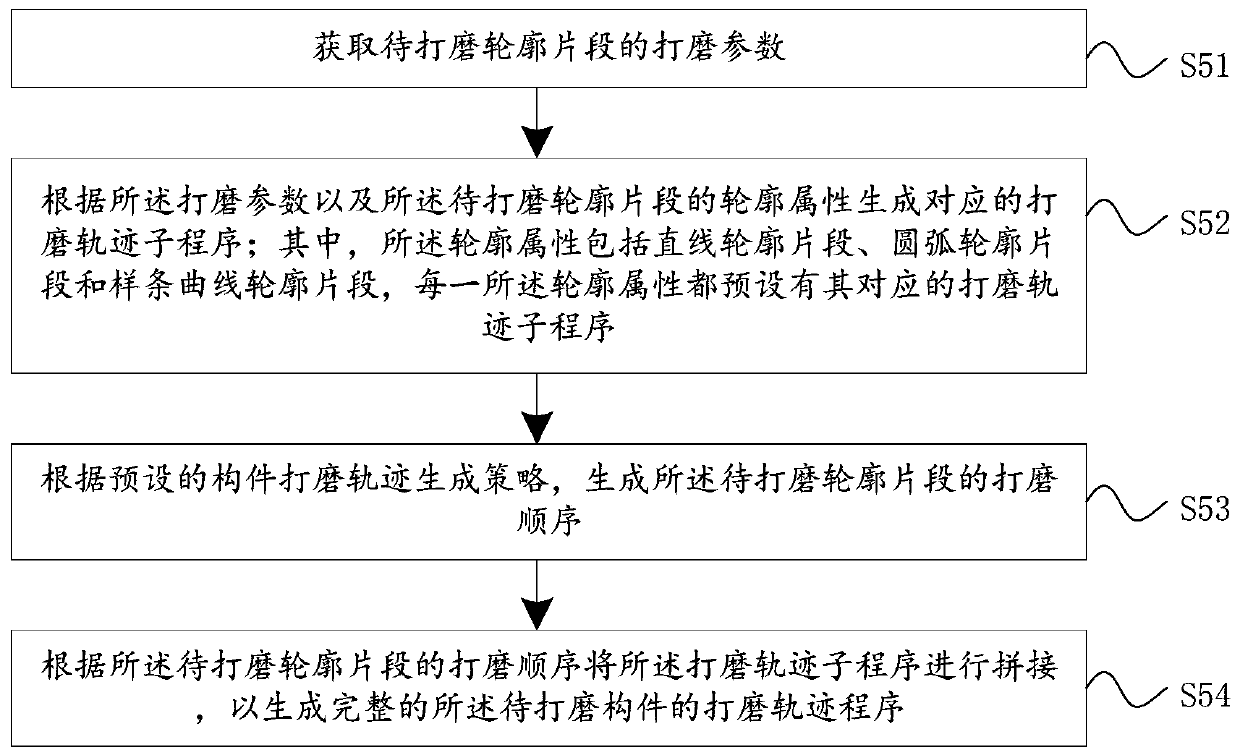

[0047] see figure 1 , figure 1It is a flow chart of a method for generating component grinding tracks provided by an embodiment of the present invention; including:

[0048] S1. Obtain the position information and contour information of the component to be polished;

[0049] S2. Extracting and displaying contour feature points and contour feature lines of the component to be polished according to the position information and contour information;

[0050] S3. Judging whether the contour feature line of the component to be polished matches the template contour in the component template database;

[0051] S4. If they match, extract the grinding trajectory program of the template contour as the grinding trajectory program of the component to be polished;

[0052] S5. If they do not match, acquire the grinding parameters of the component to be polished, so as to generate a grinding trajectory program of the component to be polished.

[0053] It is worth noting that the method f...

Embodiment 2

[0075] see Figure 5 , Figure 5 It is a structural schematic diagram of a component grinding trajectory generation device 10 provided by an embodiment of the present invention; it includes:

[0076] An information acquisition module 11, configured to acquire position information and profile information of the component to be polished;

[0077] A display module 12, configured to extract and display contour feature points and contour feature lines of the component to be polished according to the position information and contour information;

[0078] Judging module 13, for judging whether the contour feature line of the component to be polished matches the template contour in the component template database;

[0079] The grinding trajectory extraction module 14 is used to extract the grinding trajectory program of the template contour as the grinding trajectory program of the component to be polished when the contour feature line of the component to be polished matches the tem...

Embodiment 3

[0100] see Figure 6 , Figure 6 is a structural schematic diagram of a component grinding track generation device provided by an embodiment of the present invention; the component grinding track generation device 20 of this embodiment includes: a processor 21, a memory 22, and a A computer program running on the device 21. When the processor 21 executes the computer program, it realizes the steps in the embodiment of the component outline coding method, for example figure 1 Steps S1-S5 are shown. Alternatively, when the processor 21 executes the computer program, it realizes the functions of the modules / units in the above-mentioned device embodiments, for example, the information acquisition module 11 .

[0101] Exemplarily, the computer program can be divided into one or more modules / units, and the one or more modules / units are stored in the memory 22 and executed by the processor 21 to complete this invention. The one or more modules / units may be a series of computer p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com