Water injection pipeline cyclone separation desanding device

A cyclone separation and pipeline technology, which is applied in the field of cyclone separation and desanding devices for water injection pipelines, can solve the problems of sealing parts wear and tear failure leakage, waste of manpower and material resources, high pressure of water injection wells, etc., achieve no interception and pressure loss, and improve work efficiency , The effect of reducing the frequency of replacement and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

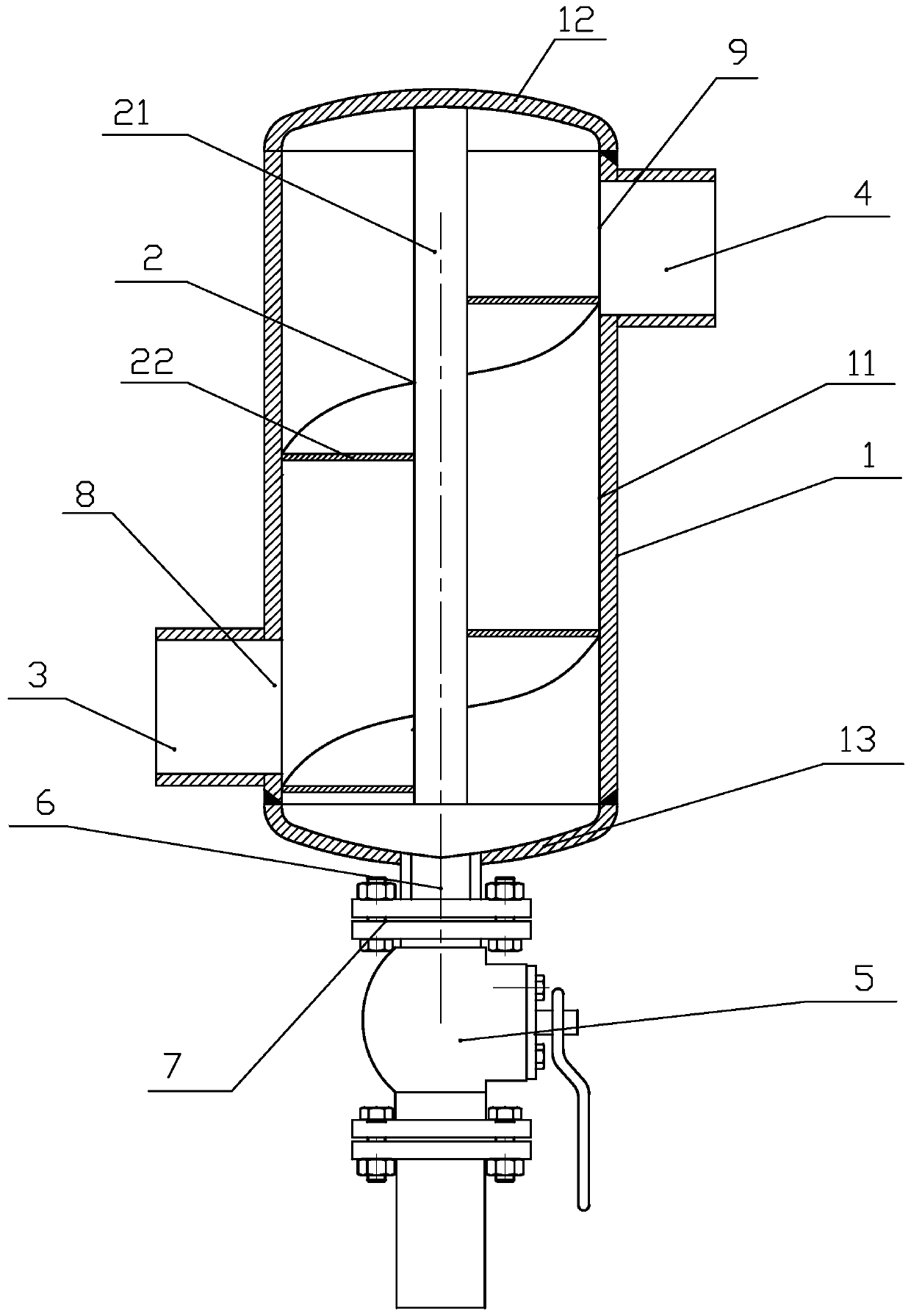

[0016] Specific implementation mode one: combine figure 1 Describe this embodiment, a water injection pipeline cyclone separation desanding device, which includes a housing 1, a screw assembly 2, a liquid inlet pipe 3, a liquid outlet pipe 4 and a sewage valve 5, and the liquid inlet pipe 3 is connected and fixed on the Outside the lower part of the housing 1, the outlet pipe 4 is communicated and fixed on the outer side of the upper part of the housing 1, the screw assembly 2 is vertically fixed in the housing 1, and the liquid inlet pipe 3 and the outlet pipe 4 pass through the screw assembly 2, the drain valve 5 is vertically arranged at the bottom of the housing 1 and is connected to the housing 1 through a connecting pipe 6 . Between the top of the drain valve 5 and the connecting pipe 6, as well as between the bottom end and the lower pipeline, are fixedly connected by flanges 7, which are convenient for disassembly and installation.

[0017] This application is install...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com