A kind of flame retardant polyamide composition

A flame-retardant polyamide and composition technology, applied in the field of polymer materials, can solve the problems of non-fibrous filler reinforcement and poor heat resistance, and achieve the effects of low equipment requirements, improved glow wire performance, and reduced production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

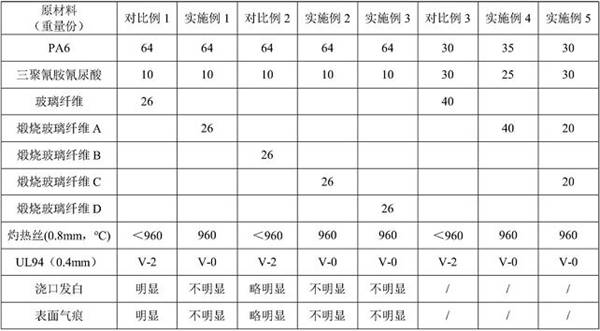

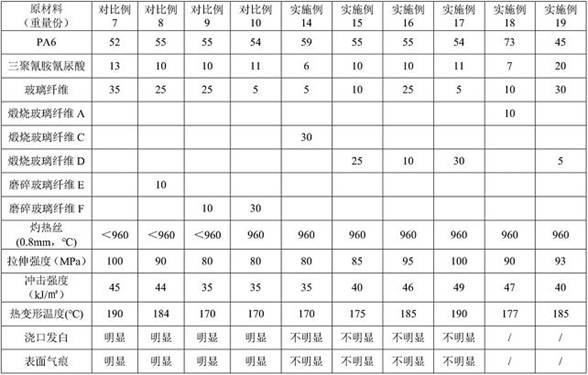

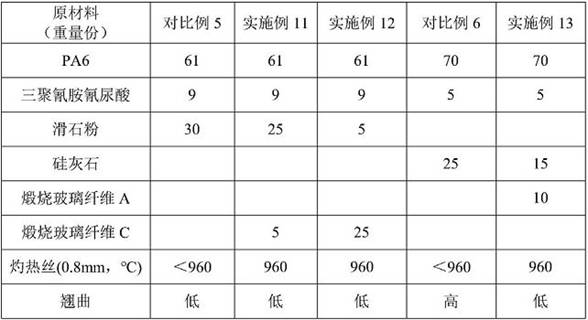

Embodiment 1-19 and comparative example 1-10

[0064] According to the formulations of the examples and comparative examples in Tables 1-4, the raw materials were weighed and blended, and the components of polyamide resin, halogen-free flame retardant, calcined glass fiber and other additive materials were mixed uniformly, and then put into twin-screw extrusion. The length-diameter ratio of the twin-screw extruder is 40:1, and the screw speed is 280rpm / min. After the particles are dried (usually dried in a vacuum drying oven at 80°C for 5-8 hours), the corresponding performance test standard specimens are formed in an injection molding machine.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com