Flame-retardant polyamide composition

A technology for flame-retardant polyamide and composition, applied in the field of polymer materials, can solve the problems of non-fibrous filler reinforcement and poor heat resistance, achieve high fire resistance, avoid wick effect, and reduce manufacturing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

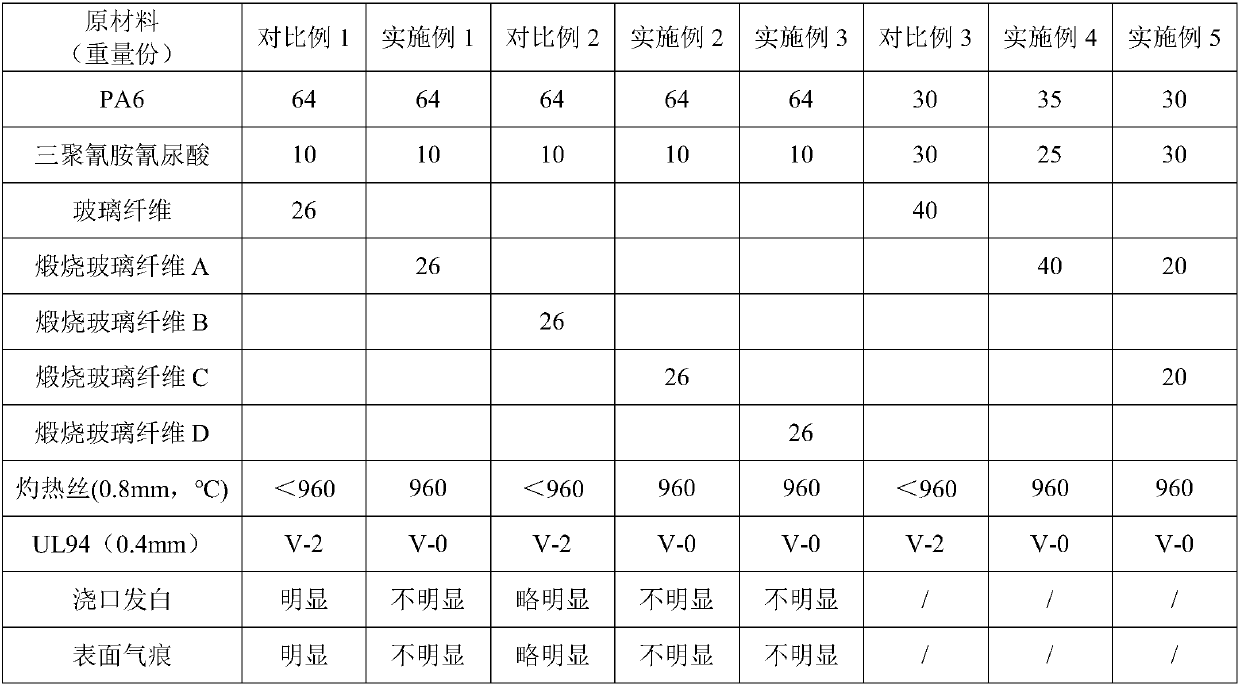

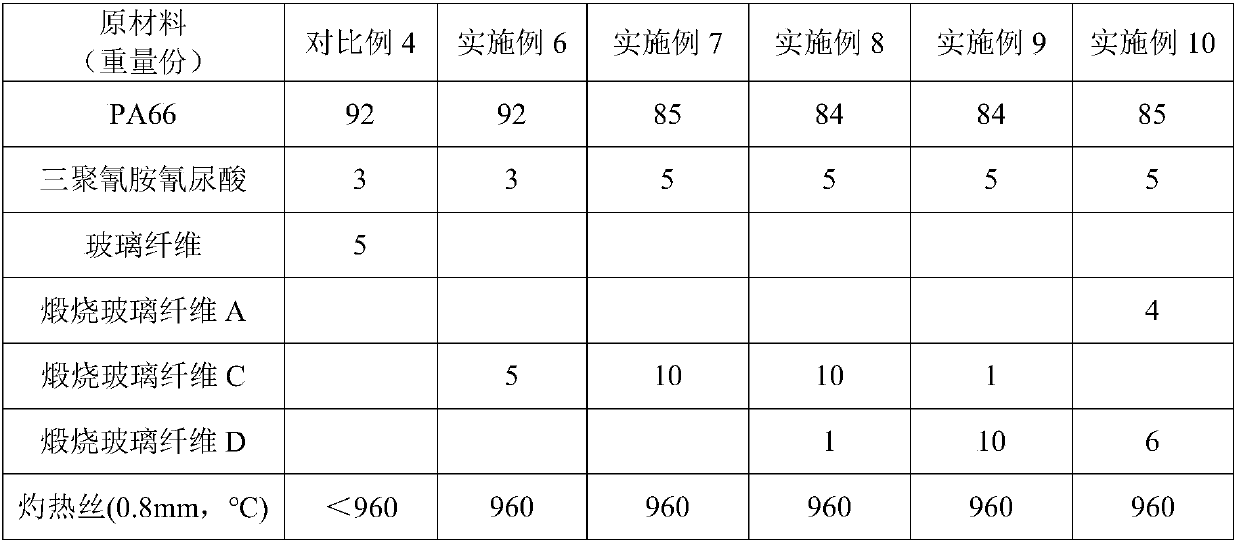

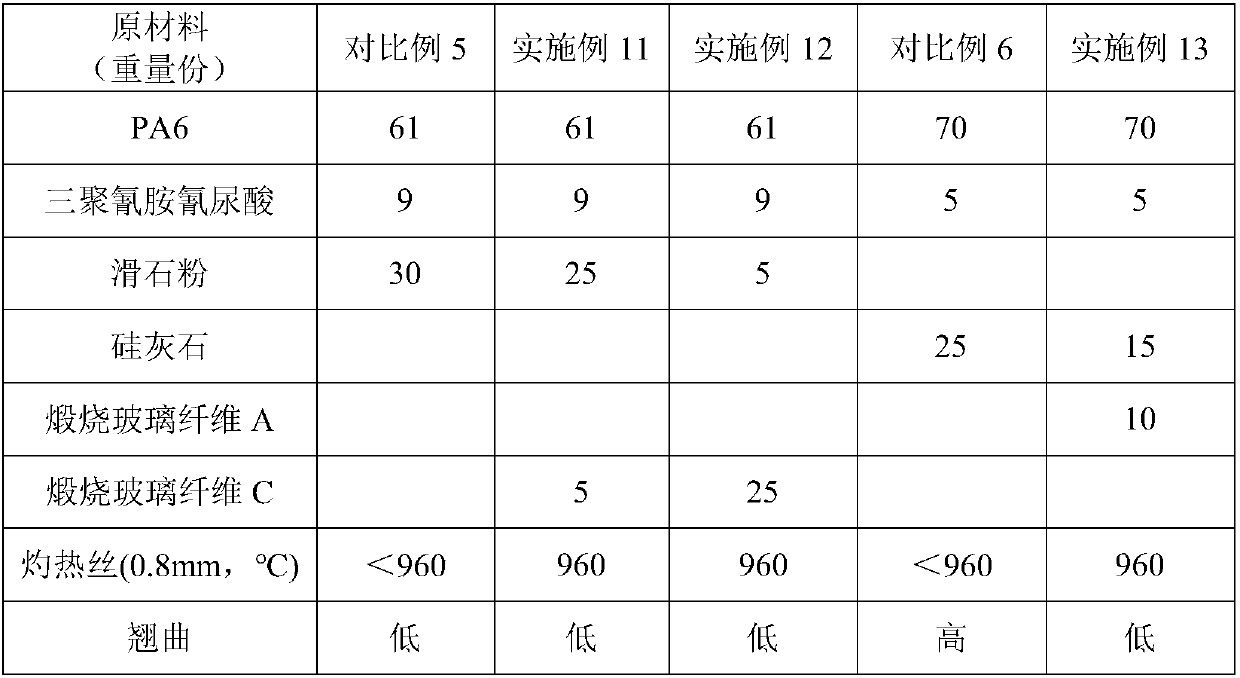

Embodiment 1-19 and comparative example 1-10

[0064] According to the formulas of each embodiment and comparative example in Table 1-4, the raw materials were weighed and blended, and the components of polyamide resin, halogen-free flame retardant, calcined glass fiber and other additive materials were first mixed evenly, and put into the twin-screw extruder Extrusion, strand drawing, cooling, air drying and granulation. The aspect ratio of the twin-screw extruder is 40:1, and the screw speed is 280rpm / min. After the particles are dried (usually in a vacuum oven at 80°C for 5-8 hours), the corresponding performance test standard specimens are molded in an injection molding machine.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com