Woven baler warp knitting machine

A technology of warp knitting machine and straw net, applied in the field of warp knitting machine, can solve the problems such as the unreasonable mechanical structure of the swing shaft of the groove needle bed, bar swing shaft, etc., achieve the simplification of the mechanical structure, simplify the mechanical structure, and increase the speed of the whole machine Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

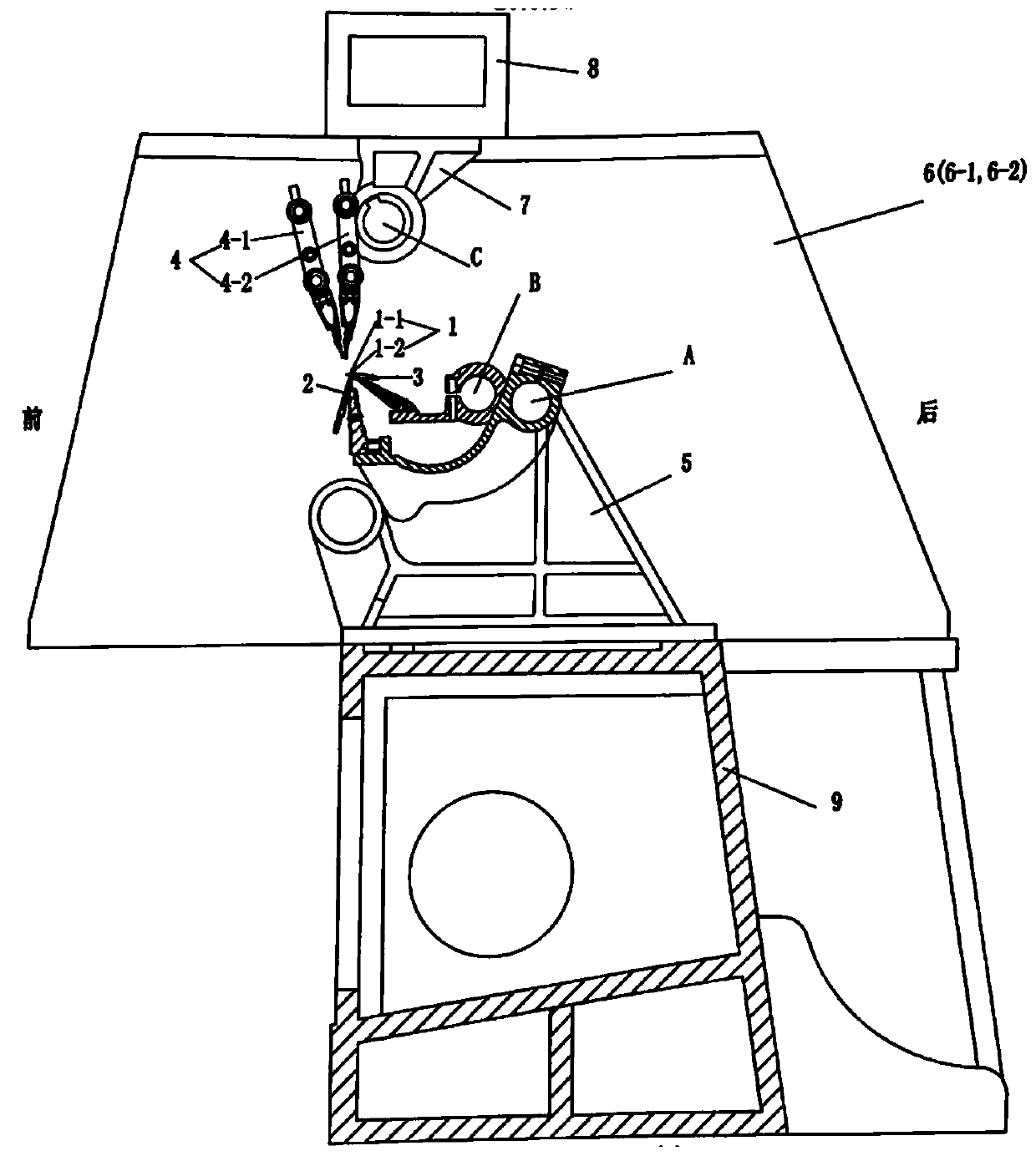

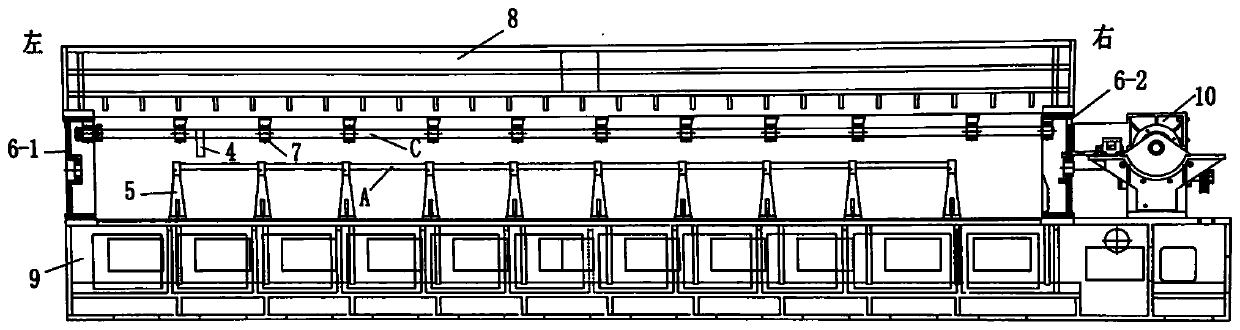

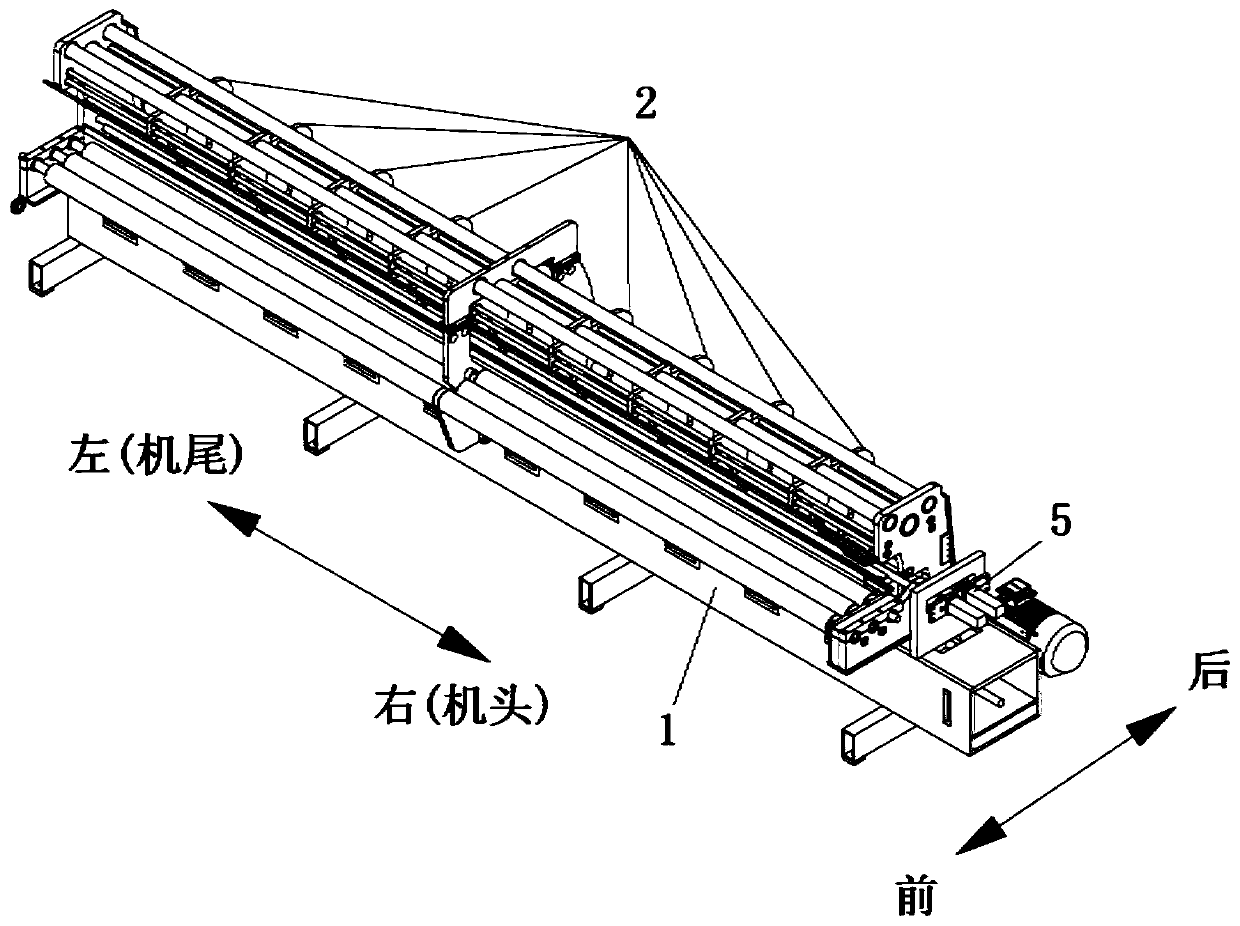

[0036] image 3 , 4 Shown in , 5 is the overall and partial structure of the bale net warp knitting machine, which is composed of an oil tank 1, a wallboard 2, a loop forming device 3, a bar 4, a traverse device 5, and pulling, coiling, and let-off, etc. Among them, the structure of oil tank 1, loop forming device 3, traverse device 5, and pulling, coiling, let-off, etc. is the same as that of commonly used warp knitting machines with few bars, and the structure and movement of wallboard 2 and bars 4 It is different from wall panels and bars in existing warp knitting machines.

[0037]Described wallboard 2 has the hole that supports groove needle pendulum shaft 6, needle core pendulum shaft 7, bar pendulum shaft 8 equiaxes, Image 6 As shown, these holes are all on the overall structure of the wallboard, and the mutual positional relationship between these holes is guaranteed by machining, so as to ensure the balance between the groove needle swing shaft 6, needle core swing...

Embodiment 2

[0053] Figure 8 Shown is another embodiment that the weft insertion bar 4-2 is installed in a fixed position and does not swing.

[0054] 12 is mounting seat, is made up of 12-1 and 12-2 two halves, and 14 is mounting shaft. Mounting shaft 14 is fixedly installed in the hole of wallboard 2 and prohibits motionless. The bolt 13 connects the two halves of the mounting base 12 - 1 and 12 - 2 into a whole, so that it is fixed on the mounting shaft 14 . Bolt 11 (11-1, 11-2) passes through the waist hole of slide bar seat 4-2-1, is tightened in the threaded hole of mounting seat 12, and weft inserting bar 4-2 is fixedly installed in mounting seat 12 superior. Also can have two light holes that pass on the mounting seat 12, bolt 11 passes light hole, utilizes nut and bolt 11 to cooperate and tighten, and weft insertion bar 4-2 is fixedly installed on the mounting seat 12.

[0055] Because mounting base 12 is fixed on the mounting shaft 14, and mounting shaft 14 is fixedly instal...

Embodiment 3

[0059] Figure 9 Shown is another embodiment of the fixed position support to which the weft insertion bar 4-2 is mounted.

[0060] 15 is a hanging seat, which is made up of two halves of 15-1 and 15-2. There are semicircular holes on 15-1 and 15-2, and 15-1 and 15-2 are fixed on the connecting shaft 9 by bolts, as Install the fixing seat of the weft inserting bar. The suspension seat 15 is installed between the parallel wallboards 2, a suspension seat 15 is installed between every two wallboards, and a suspension seat 15 can also be installed between the multi-bar wallboards.

[0061] Threaded hole is arranged on the suspension seat 15, or the light hole of passing through, by bolt 10, weft insertion bar 4-2 is fixed on the suspension seat 15.

[0062] The mechanical structure of the weft-inserting bar of the present invention is the same as that of the existing machine, and the structure of the traversing motion device is different. Since no swing is required, the new stru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com