Preheater

A preheater and preheating cylinder technology, applied in chemical instruments and methods, lamination auxiliary operations, lamination, etc., can solve problems such as paper tension considerations, production process paper breaks, etc., to achieve precise water control and reduce paper The effect of scrap rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

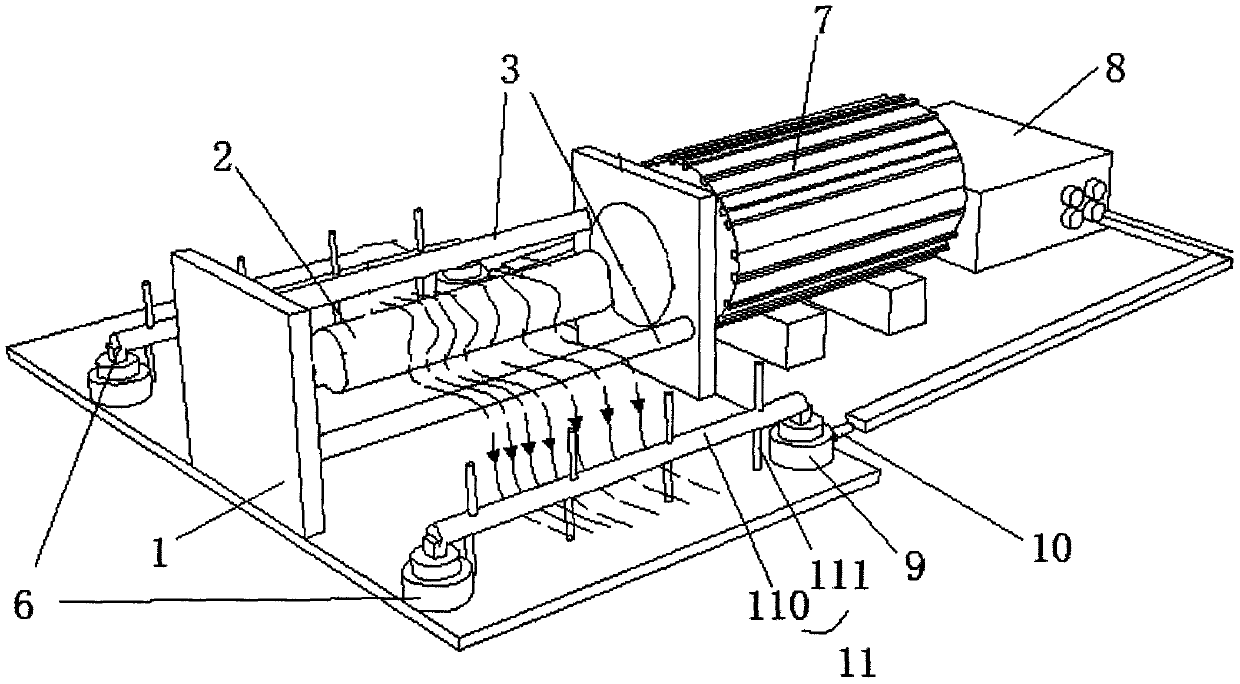

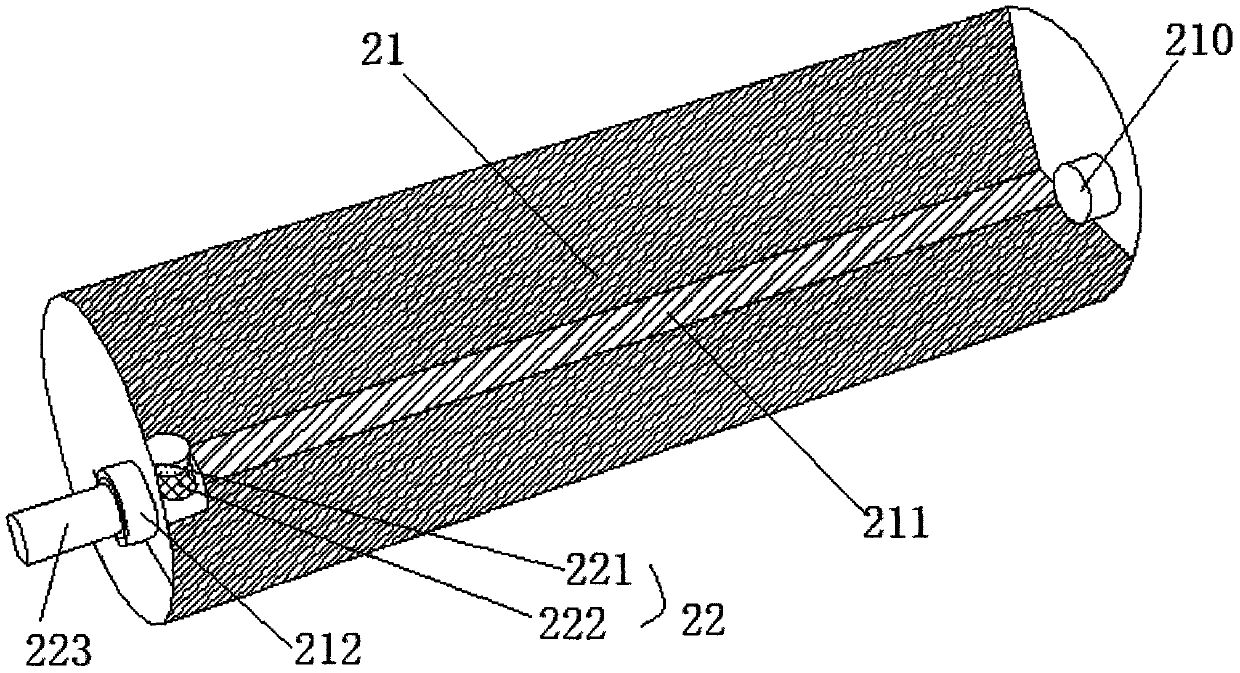

[0020] Such as figure 1 , 2 As shown, a preheater includes a frame 1, a preheating cylinder 2, and a paper guide roller 3, and the preheating cylinder 2 and the paper guide roller 3 are arranged on the frame 1, and also includes a humidity sensor, a servo motor 7. The controller 8, the humidity sensor is arranged at one end of the preheating cylinder 2 for paper feeding, the servo motor 7 is arranged on the frame 1, and the controller 8 is electrically connected with the humidity sensor and the servo motor 7 respectively The preheating cylinder 2 is cylindrical, and the preheating cylinder 2 is provided with a preheating chamber 21 in contact with corrugated paper. The fan-shaped arc of the preheating chamber 21 is 120 degrees, and the preheating chamber 21 is provided with a steam inlet 210; The preheating cylinder 2 is provided with a tension control mechanism 6 for controlling the tension of the paper on the paper feed side and the paper discharge side. The runner 11, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com