A transmission mechanism with compact structure and wide transmission ratio

A transmission mechanism, a technology with a compact structure, applied in the transmission device, transmission device parts, transmission device control and other directions, to achieve the effect of compact components, small size and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

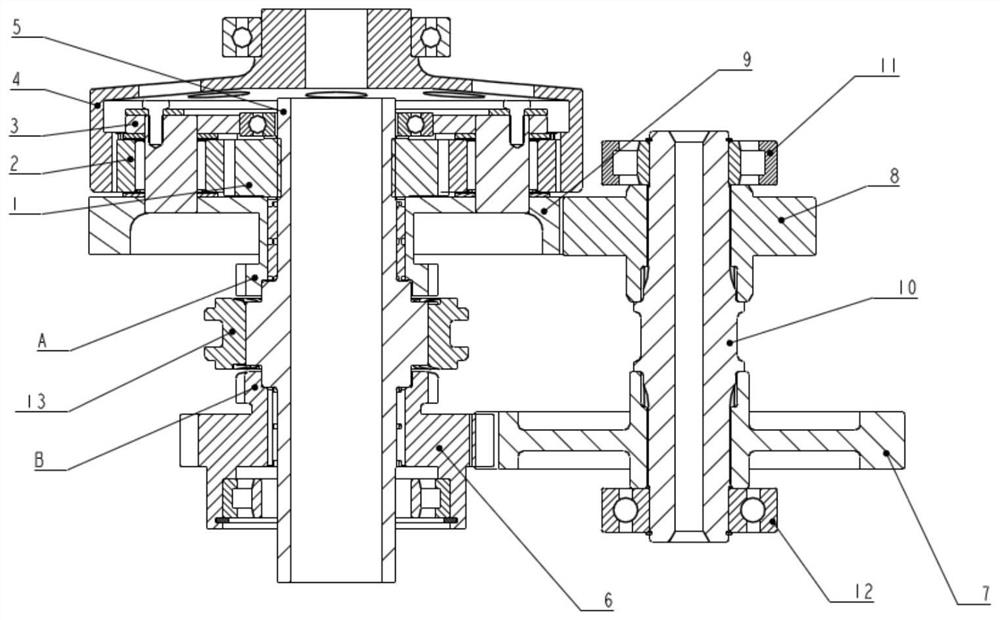

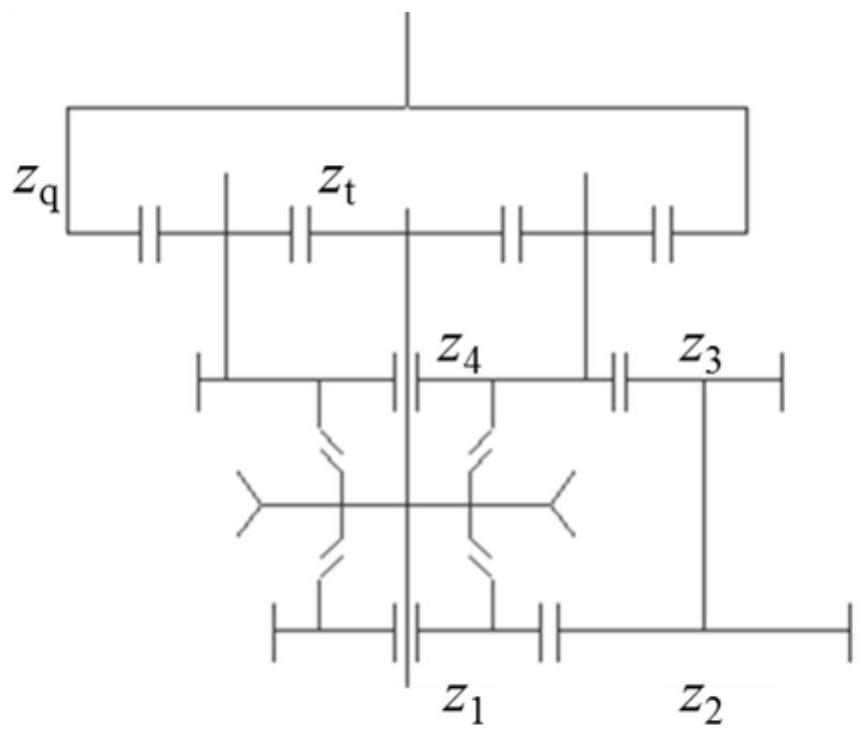

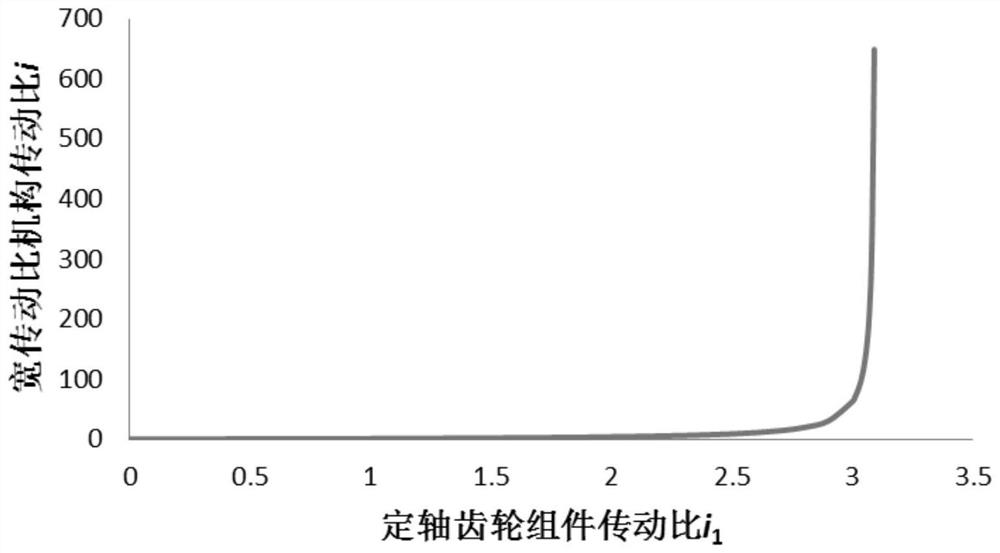

[0033] Such as Figure 1 to Figure 2 As shown, the present invention provides a transmission mechanism with a compact structure and a wide transmission ratio. Connected fixed shaft gear assembly;

[0034] The sun gear 1 is sleeved on the input shaft 5, and the ring gear 4 is connected with the output shaft;

[0035] The fixed shaft gear assembly includes a first spur gear 6 sleeved on the input shaft 5, a second spur gear 9 fixedly connected to the planet carrier, and a third spur gear sleeved on the transmission shaft 10 respectively. 7 and the fourth spur gear 8; the first spur gear 6 meshes with the third spur gear 7; the second spur gear 9 meshes with the fourth spur gear 8;

[0036] A shift fork sleeved on the input shaft 5 is provided between the first spur gear 6 and the sun gear 1; A fixed piece A and a low-speed fixed piece B; the high-speed fixed piece A is connected to the second spur gear 9 , and the low-speed fixed piece B is connected to the first spur gear 6 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com