Boiler flue gas temperature adjusting device and adjusting method thereof

A temperature adjustment device, boiler flue gas technology, applied in the direction of reducing greenhouse gases, climate sustainability, feed water heaters, etc. , to avoid the effect of excessive volatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with specific embodiments and with reference to the accompanying drawings. Wherein the same components are denoted by the same reference numerals. It should be noted that the words "front", "rear", "left", "right", "upper" and "lower" used in the following description refer to directions in the drawings. The terms "inner" and "outer" are used to refer to directions toward or away from, respectively, the geometric center of a particular component.

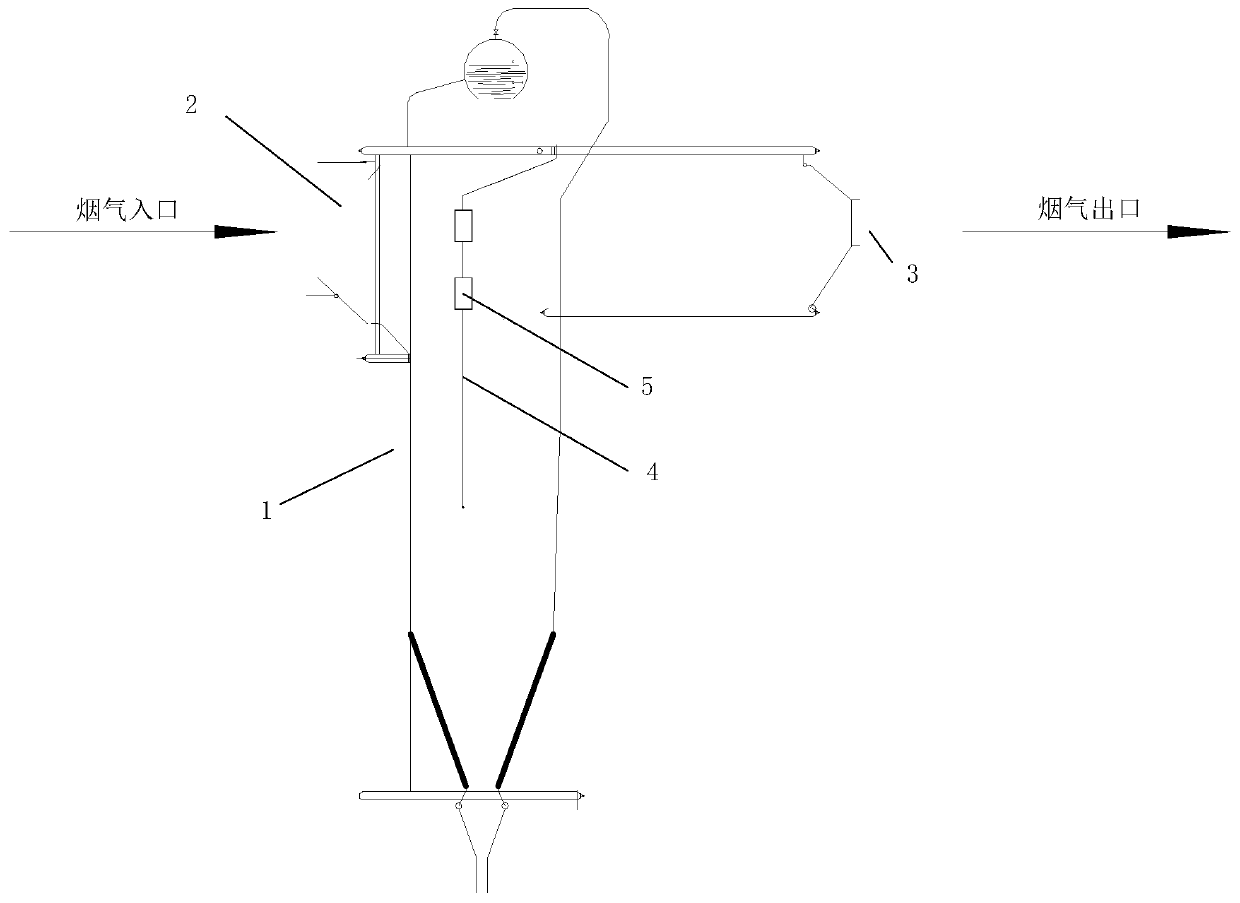

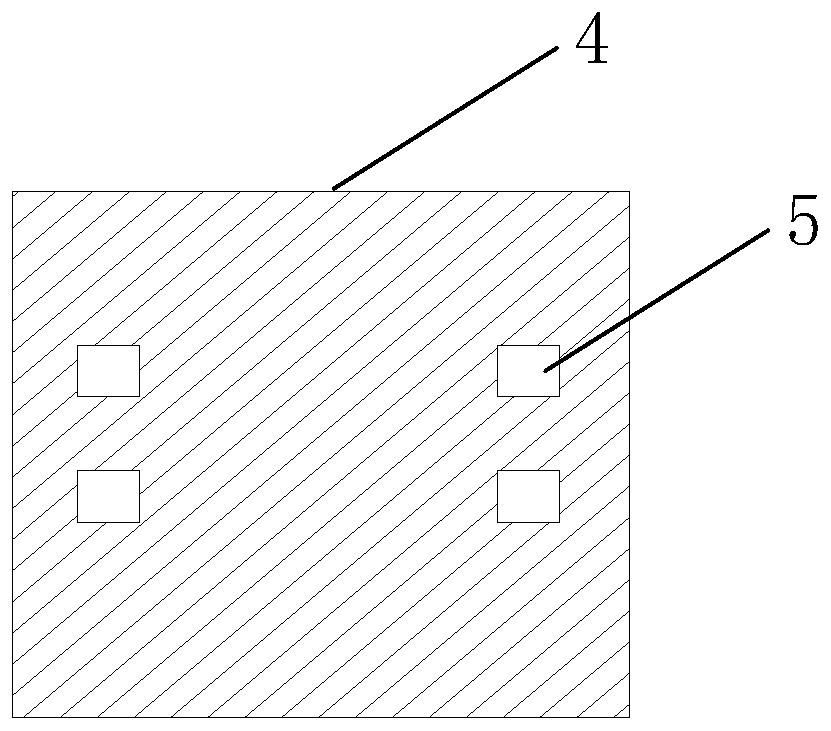

[0028] figure 1 It is a schematic diagram of a boiler flue gas temperature regulating device installed in a boiler and adopted in a specific embodiment of the present invention. Such as figure 1 As shown, the boiler 1 includes an installation port, an air inlet 2 and an air outlet 3 that are oppositely arranged, and the boiler flue gas temperature re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com