Polypropylene melt index hybrid modeling method based on dynamic error compensation mechanism

A compensation mechanism and melt index technology, applied in chemical machine learning, chemical data mining, chemical property prediction, etc., can solve problems such as inability to guarantee prediction accuracy and weak model stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0073] The present invention will be further described below in conjunction with the accompanying drawings.

[0074] refer to Figure 1 to Figure 7 , a polypropylene melt index mixing modeling method based on a dynamic error compensation mechanism, including the following steps:

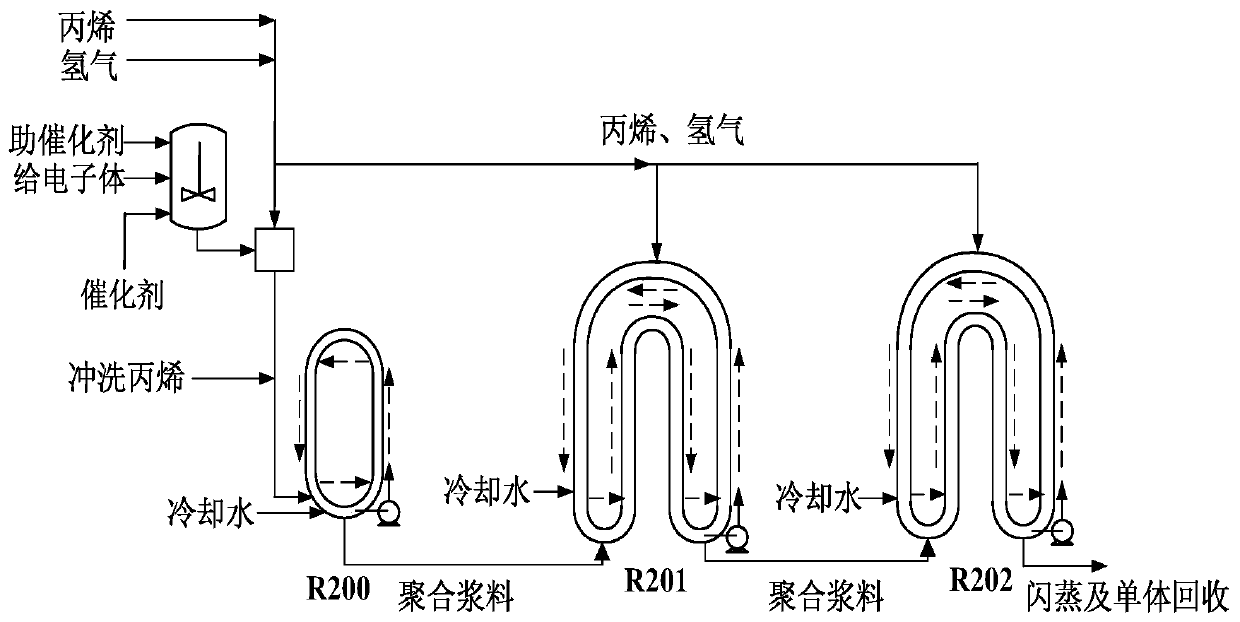

[0075] 1) The process diagram of the double-loop polypropylene production unit in a petrochemical enterprise is as follows figure 1 As shown, on the basis of detailed analysis of propylene polymerization kinetics and Spheripol double-loop process characteristics, the appropriate auxiliary variables and leading variables are selected. Auxiliary variables for polypropylene melt index soft measurement include first loop hydrogen concentration H 21 (ppm), hydrogen concentration H in the second loop 22 (ppm), catalyst flow rate C cat (kg / h), the first loop propylene monomer flow rate C 31 (t / h), second loop propylene monomer flow rate C 32 (t / h), the first loop reactor temperature T 1 (°C), second ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com