Hot aisle equipment with overload protection

An overload protection and hot channel technology, applied in the field of hot channel equipment, can solve the problems of closed needle damage, undetected adjustment to impermissible positions, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] If terms such as upper and lower or right and left are used below, these relate to the positions shown in the respective figures. The loading location can be different from it so that the concepts are relative to each other.

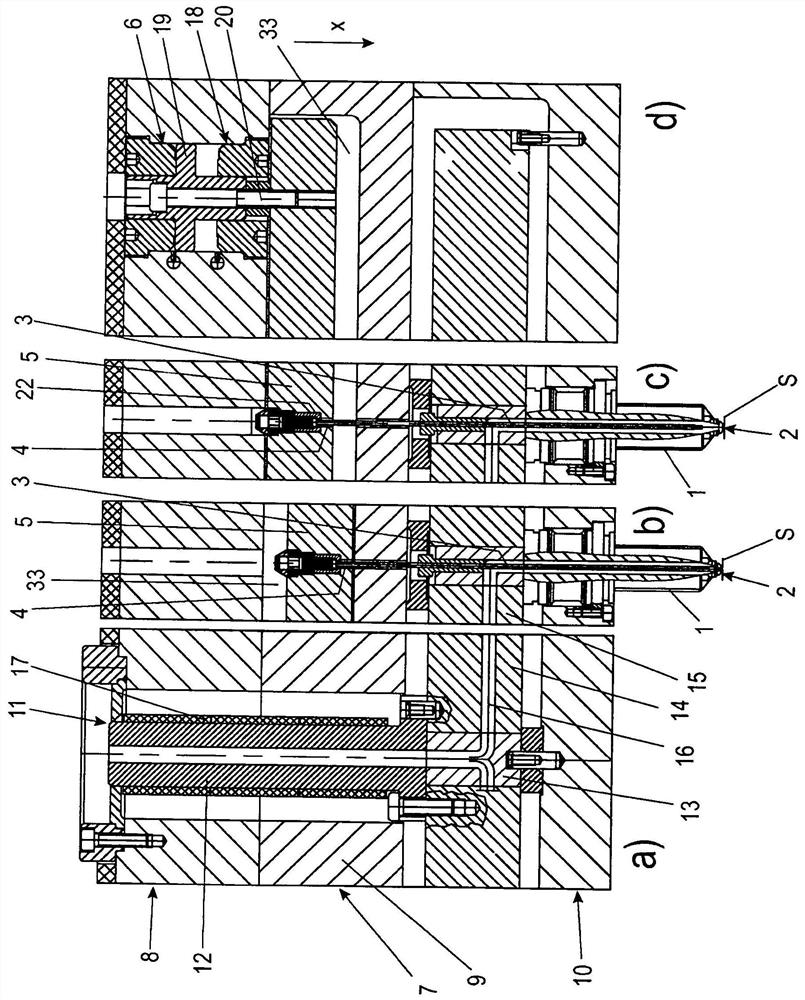

[0030] figure 1 In the interaction of parts a), b) and d) or a), c) and d), a sectional view of a section of a hot runner device with a needle closure nozzle 1 is shown in each case. This equipment is designed for injection molding of plastic components. The plastic component is injection-moulded in a mold, which is indicated here only by the line S as a shaped plate with openings and is otherwise not shown (see DE 10 2015 216 059 A1 for this, for example), which generally has a shaped plate with casting holes.

[0031] figure 1into four parts which are arranged at a distance from each other here for simplicity, wherein parts a), b) and d) show the hot runner device in the closed position in an imaginary connected state, and part a) , c) and d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com