Regulating raw material for improving aging rate of baked steamed bread and strengthening nutrition and application thereof, and method for improving aging rate of baked steamed bread

A technology for raw materials and baked buns, which is applied in the application, baking, dough processing and other directions, and can solve the problems of hard texture, single nutrition, and long baking and curing time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

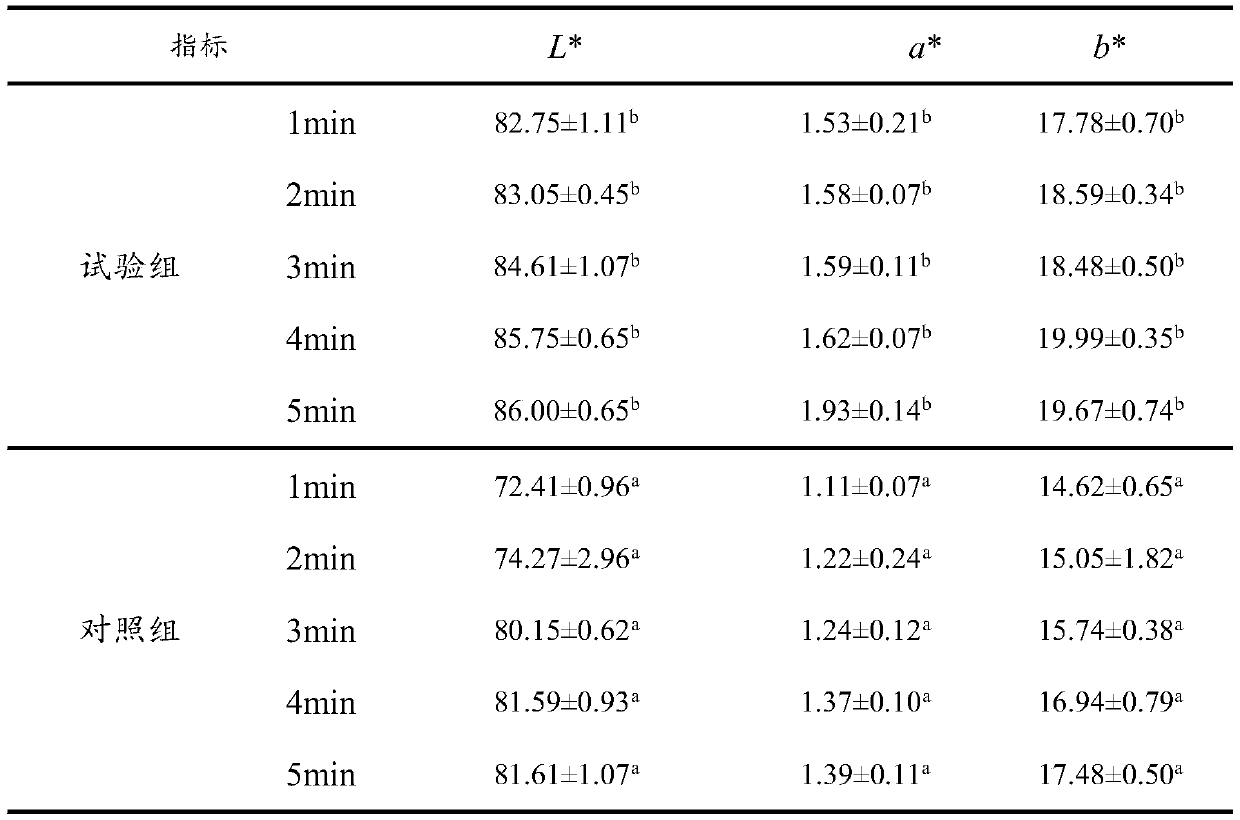

Image

Examples

Embodiment 1

[0038] 1. Grind the whole potato powder in a high-speed mill to form an adjusted raw material with a particle size of 100 μm, uniform dispersion, and unchanged physical properties;

[0039] 2. Fully mix the adjusted raw material prepared in step 1 with pure wheat flour according to the mass ratio of 15:100 to obtain the raw material for baked bun;

[0040] 3. Add water and flour to the baked bun ingredients, and ferment, add oil, sugar, eggs, yeast, salt and alkali to the fermented dough, and then steam; after steaming, send it to the oven and bake at 150°C until fully cooked. Pack it after cooling to get the baked bun.

Embodiment 2

[0042] 1. Grind the lily powder in a high-speed mill to form an adjusted raw material with a particle size of 200 μm, uniform dispersion, and unchanged physical properties;

[0043] 2. Fully mix the adjusted raw material prepared in step 1 with pure wheat flour according to the mass ratio of 15:100 to obtain the raw material for baked bun;

[0044] 3. Add water and flour to the baked bun ingredients, and ferment, add oil, sugar, eggs, yeast, salt and alkali to the fermented dough, and then steam; after steaming, send it to the oven and bake at 150°C until fully cooked. Pack it after cooling to get the baked bun.

Embodiment 3

[0046] 1. After mixing the whole potato powder and lily powder according to the mass ratio of 65:35, grind it in a high-speed mill to form an adjusted raw material with a particle size of 100 μm, uniform dispersion, and no change in physical properties;

[0047] 2. Fully mix the adjusted raw material prepared in step 1 with pure wheat flour according to the mass ratio of 15:100 to obtain the raw material for baked bun;

[0048] 3. Add water and flour to the baked bun ingredients, and ferment, add oil, sugar, eggs, yeast, salt and alkali to the fermented dough and steam it; after steaming, send it to the oven and bake it at 150°C until it is fully cooked. Pack it after cooling to get the baked bun.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com