Mobile dust removing equipment and dust removing method of mobile sieving and crushing equipment

A technology of dust removal equipment and crushing equipment, which is applied in separation methods, chemical instruments and methods, and dispersed particle separation, etc., can solve the problems of manual dust removal, air environment pollution, and difficulty in realizing long-term continuous work, and achieves widening work adaptation. Scope, good handling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below through specific embodiments.

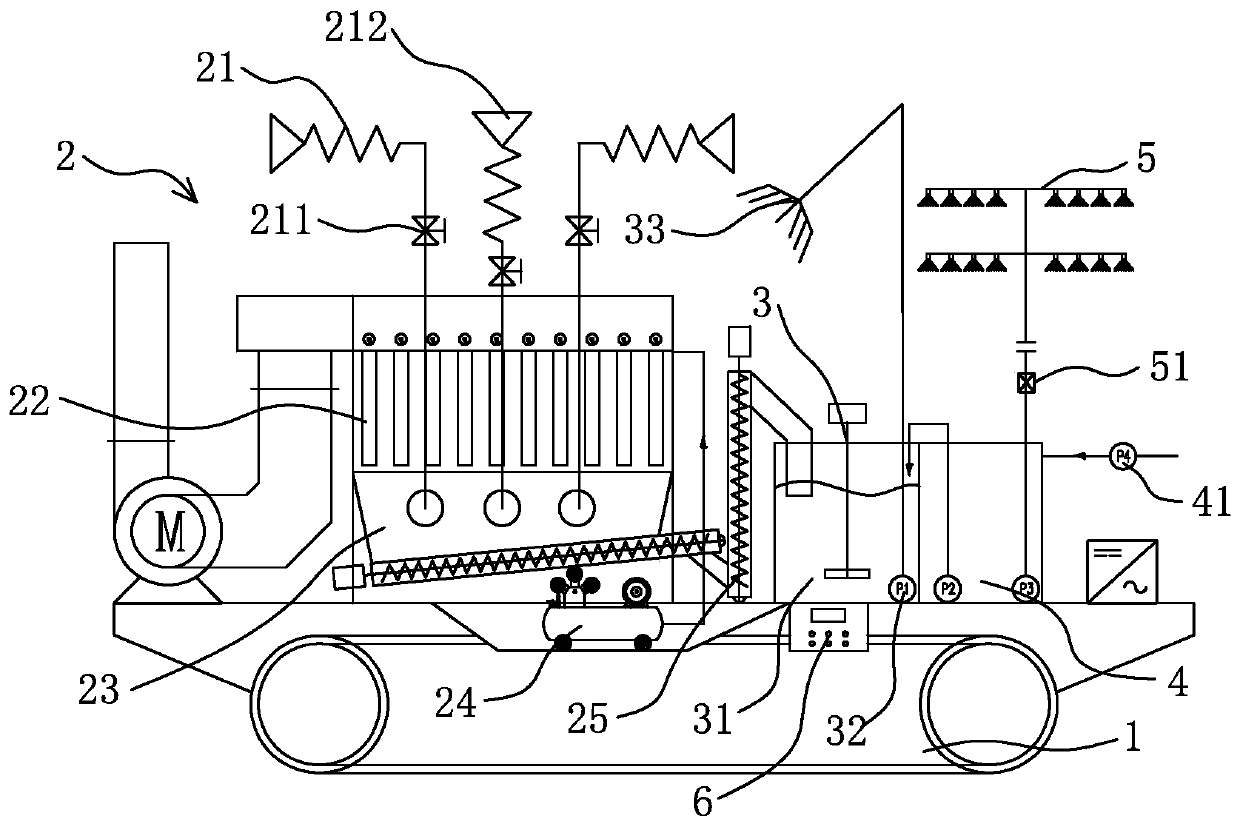

[0021] refer to figure 1 As shown, a mobile dust removal equipment is used in conjunction with mobile screening and crushing equipment, including a mobile mechanism 1, a dust collection mechanism 2, a powder processing mechanism 3, a water tank 4, a sprinkler 5, and a controller 6.

[0022] The moving mechanism 1 is a crawler belt walking mechanism, which can walk on complex mines and stones.

[0023] The powder processing mechanism 3 includes a mixing box 31 and a mud pump 32. The mixing box 31 is connected to the dust collection mechanism 2, and is used to send the powder absorbed by the dust collection mechanism 2 into the mixing box 31. The mixing box 31 is connected to the water tank 4, and the water pump The water in the water tank 4 is sent into the stirring tank 31, and the stirring rod 31 is provided with a stirring rod, which can mix powder and water to form mud water, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com