Method for continuously pulping to wash sand

A sand washing and pulping technology, which is applied to chemical instruments and methods, cleaning methods and utensils, cleaning methods using liquids, etc., can solve the problems of increasing the cost of sand treatment, difficulty in separating stones, and shutdown of the entire line, so as to achieve convenience The effect of direct recycling, improving the utilization rate of raw materials, and preventing mud sedimentation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and preferred embodiments.

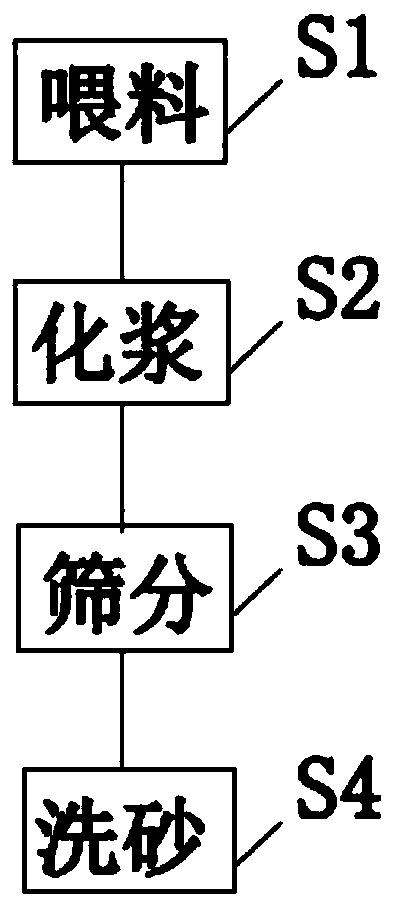

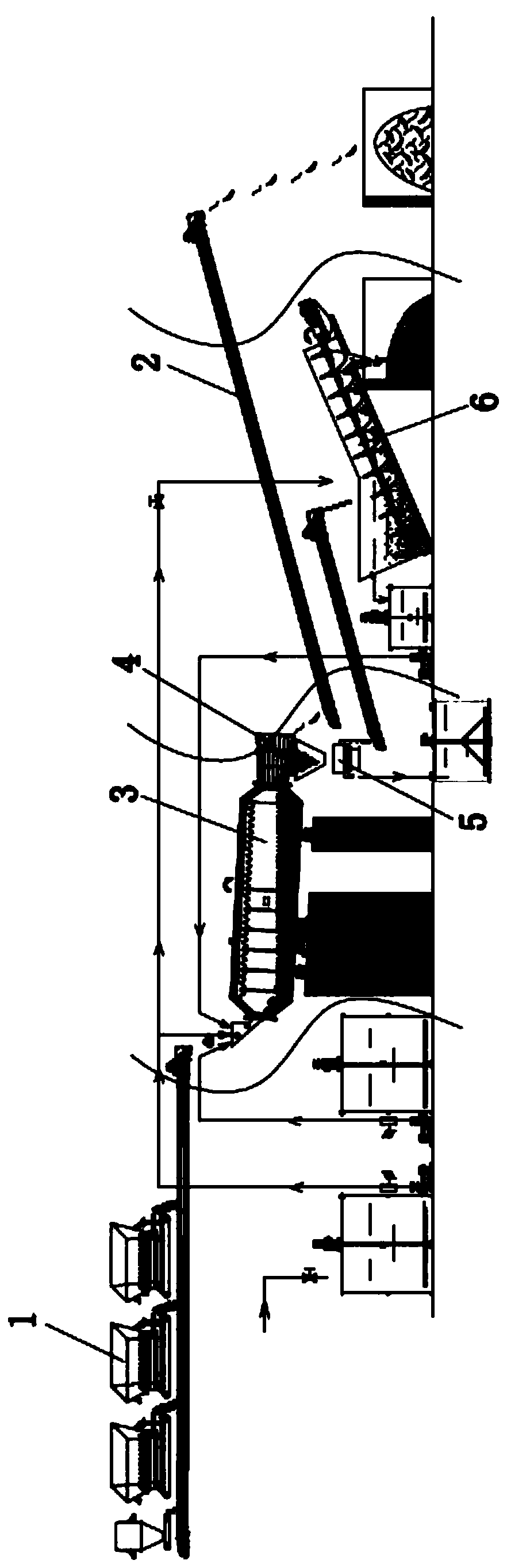

[0043] like Figure 1-5 Shown, a kind of continuous slurry washing method comprises the following steps:

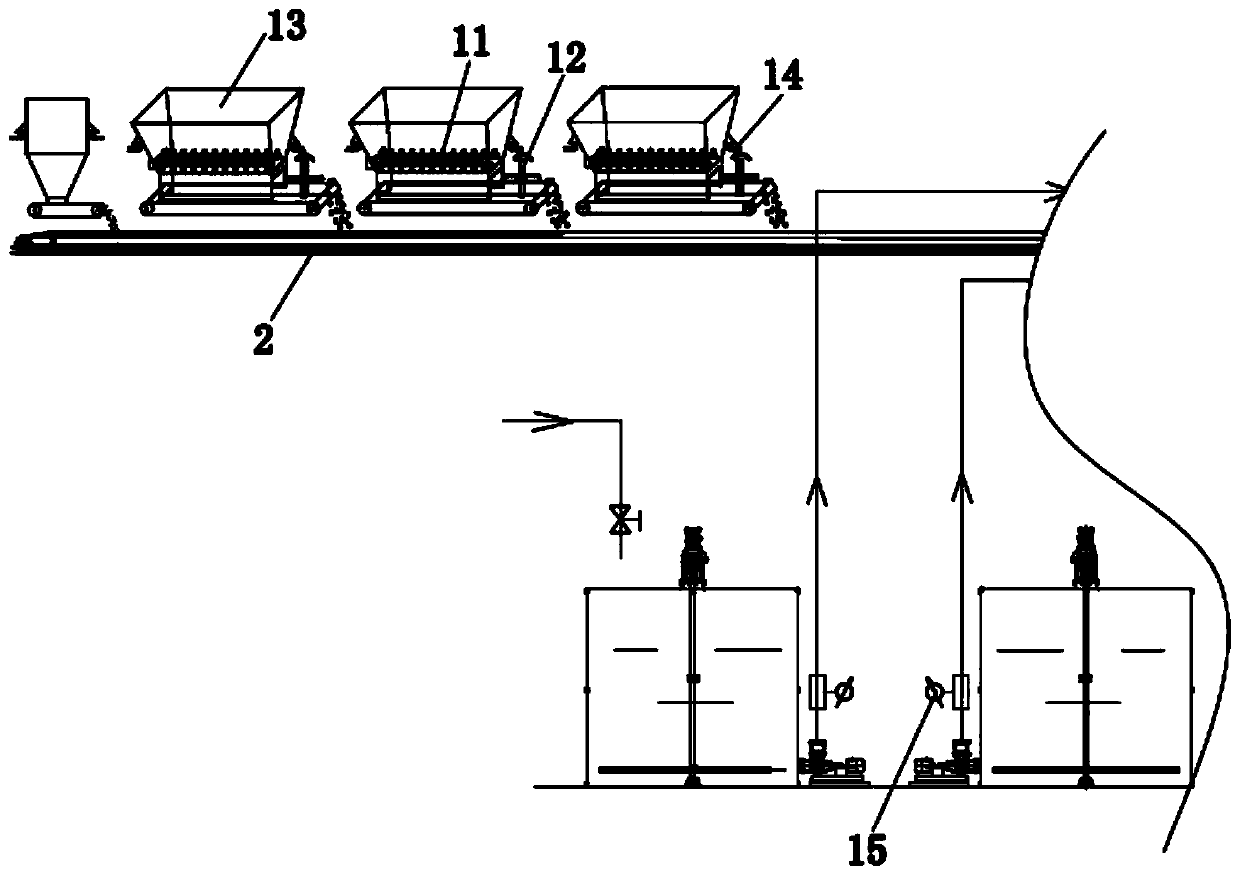

[0044] S1 feeding: raw materials are provided by the feeding mechanism 1, wherein the raw materials include mud, solid additives, liquid additives and water, and the mud is crushed by the arch-breaking stirring knife 11 and the mud crushing knife 12 in turn, and the crushed mud is Transported to the inside of the pulping mechanism 3 through the transmission mechanism 2, the solid additives are transported to the inside of the pulping mechanism 3 through the transmission mechanism 2, and the liquid additives and water are transported to the inside of the pulping mechanism 3 through pumps and pipelines;

[0045] Spec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com