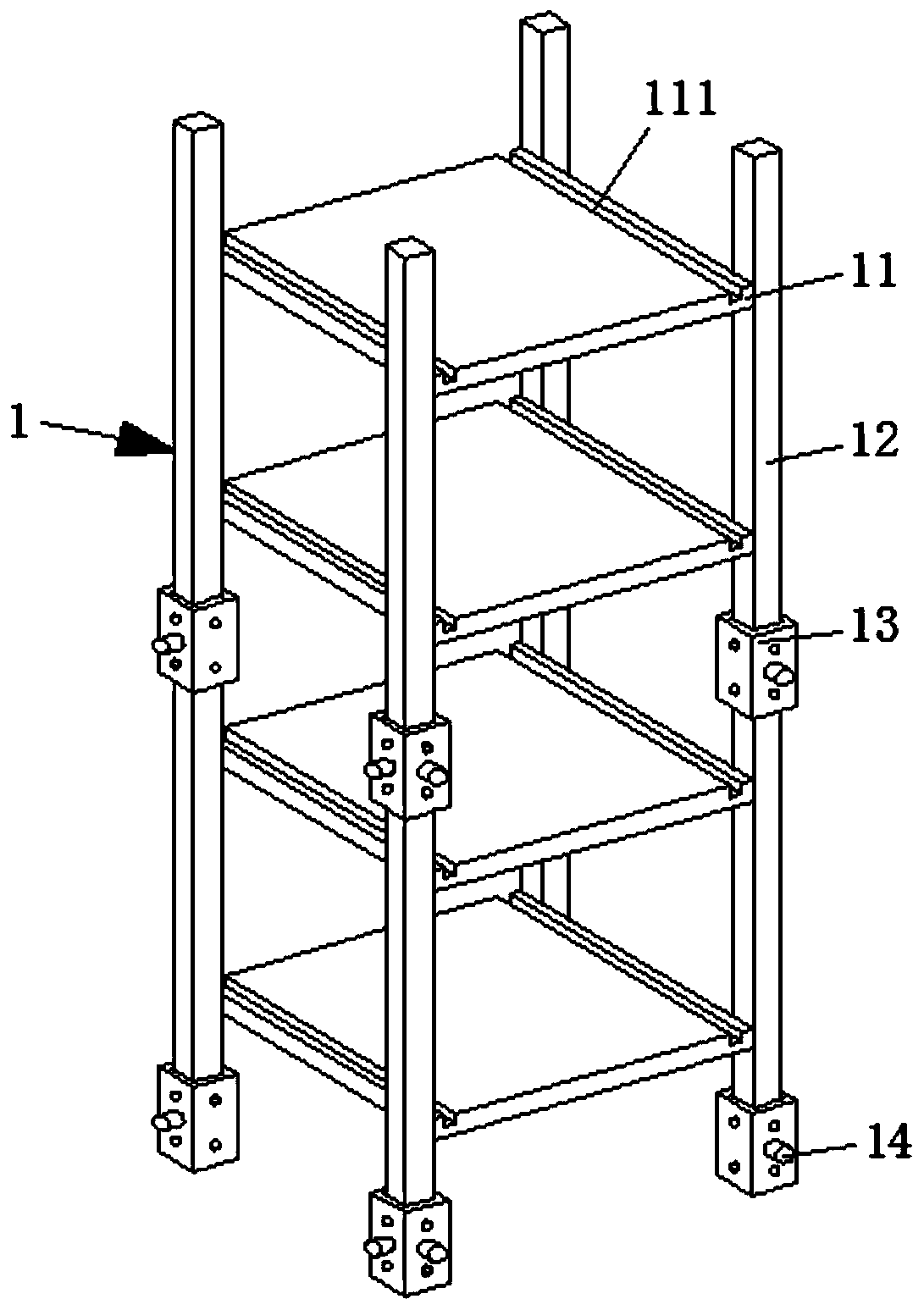

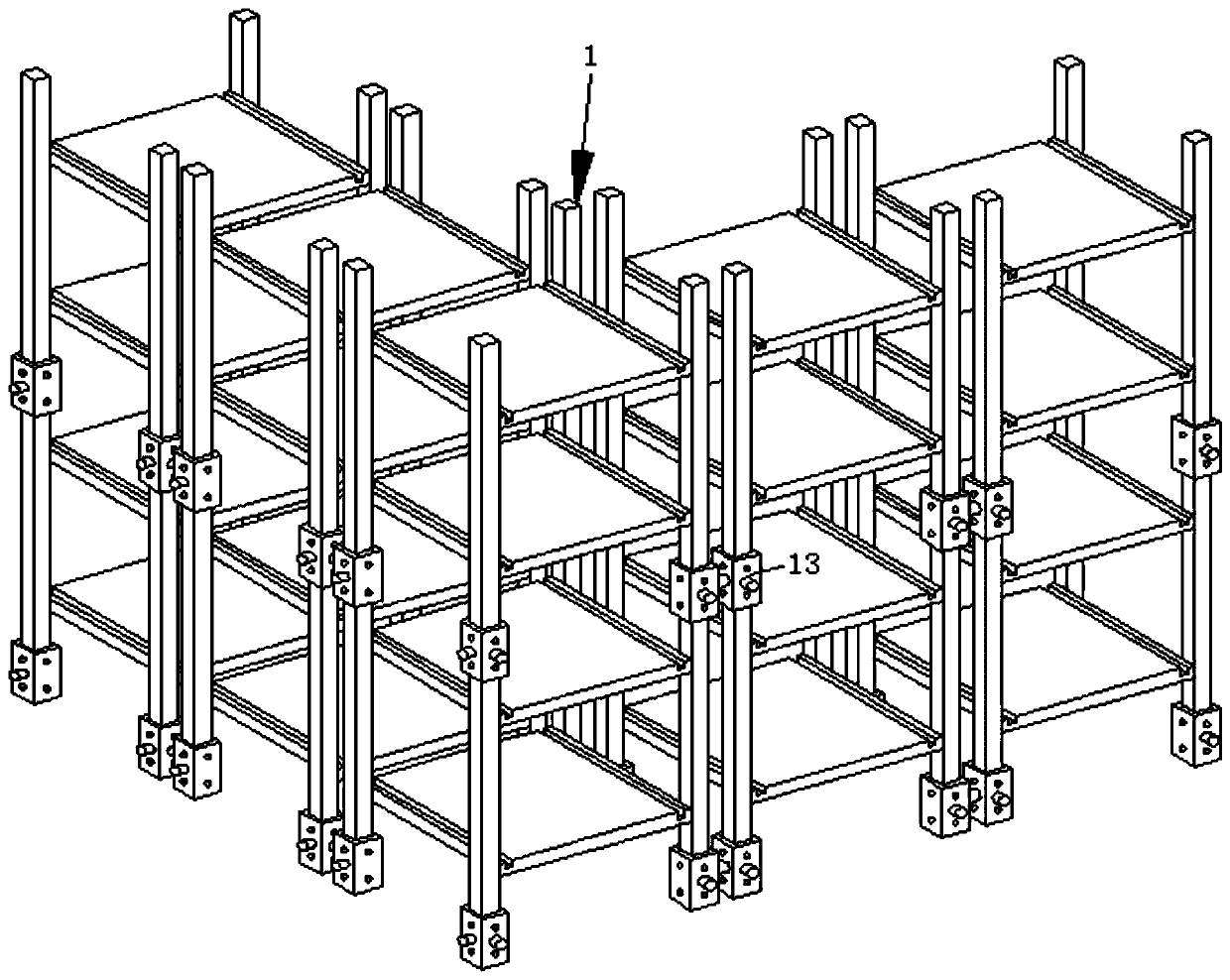

Combined three-dimensional shelf and automatic loading and unloading mechanism thereof

A three-dimensional shelf and automatic loading and unloading technology, which is applied in the field of shelves, can solve the problems of increasing logistics flow and increasing the storage capacity of small and medium-sized warehouses, and achieve the effects of easy control, reduced manual labor intensity, and improved storage capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

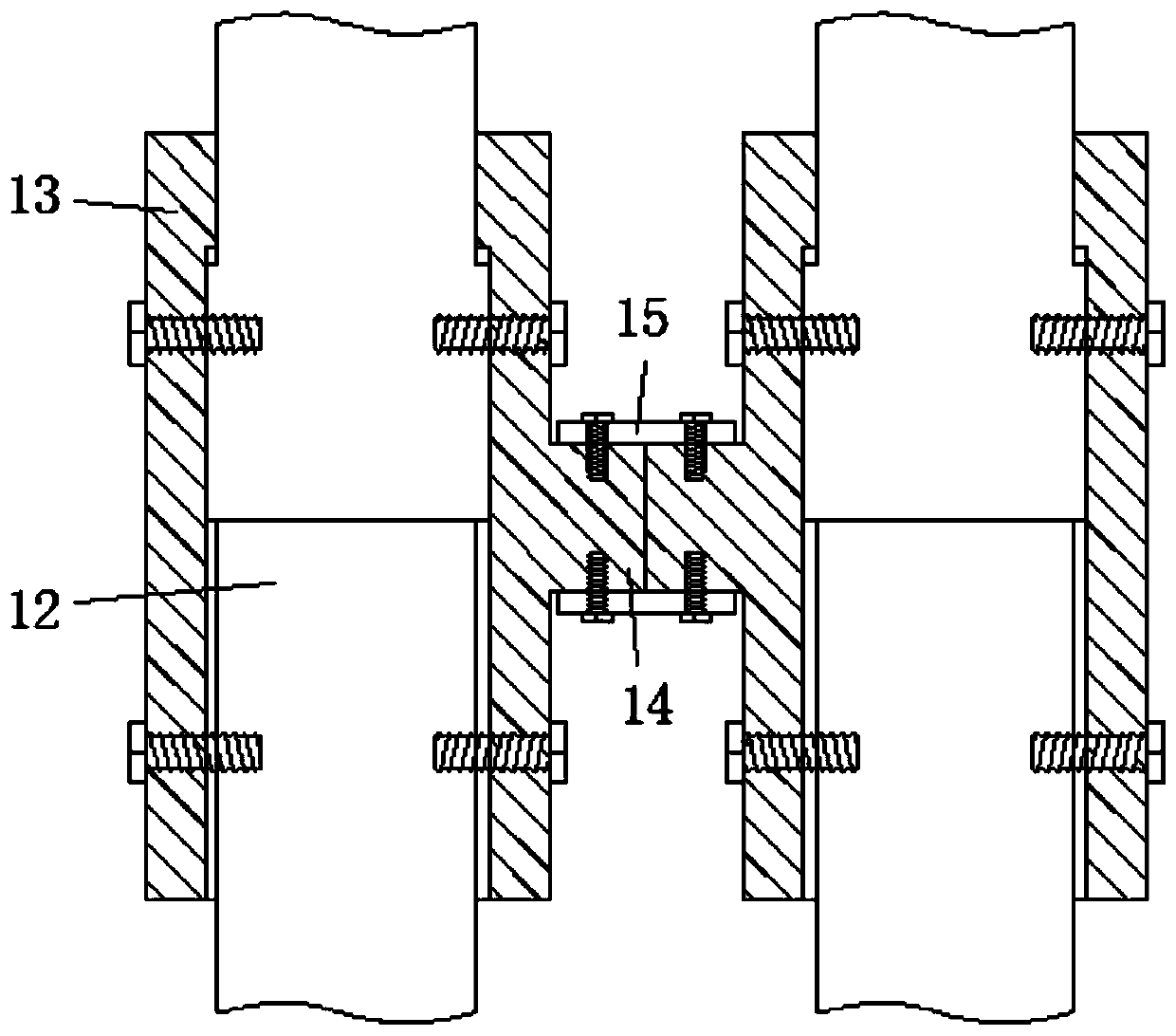

Embodiment 1

[0066] Not shown in the figure, both i and ii are empty laminates, set the clamping manipulator 3 to be positioned on i, at this time, the infrared positioning probe 313 detects within the diameter range of 3L, and can detect an object in front of i (i.e. ii), in this state, the second walking trolley 312 continues to move, so that the material clamping manipulator 3 is transferred to i, thereby completing the transfer of the material clamping manipulator 3 between the empty layers, to ensure that the material clamping manipulator 3 can effectively Realize the movement inside the shelf body 1;

Embodiment 2

[0068] Figure 12 As shown, i is an empty shelf, and ii is a shelf that has been placed with items. At this time, the clamping manipulator 3 moves to i, and the infrared positioning probe 313 detects within the diameter range of 3L, and can detect that there are two shelves in front of i. objects (i.e. the items stored on ii and ii), in this state the second walking trolley 312 stops moving, and performs a discharging operation, so that the items carried on the gripping manipulator 3 are placed on i, thereby accurately realizing The orderly discharge of the clamping manipulator 3 inside the shelf body 1;

Embodiment 3

[0070] Figure 13 As shown, i is an empty layer, and the infrared positioning probe 313 detects that there is no object in front of i, and the second walking trolley 312 stops moving at this time, and performs the discharging operation; in this embodiment, i represents the overall three-dimensional shelf Laminates at the edge, under this setting, can effectively avoid the phenomenon of excessive movement of the clamping manipulator 3, thereby ensuring the safety of the material clamping manipulator 3 moving and placing materials inside the shelf body 1;

[0071] In addition, when the hoisting device 23 drives the lifting plate 24 and the clamping manipulator 3 to carry out the lifting operation, it also uses the infrared positioning probe 313 to detect and locate the position of the lifting plate 24. The specific detection principle is the same as the above process: After loading the item at the bottom position, it is lifted, and the infrared positioning probe 313 detects from...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com