Knitting machine cross beam and production process thereof

A production process and knitting machine technology, applied in knitting, weft knitting, warp knitting, etc., can solve the problems that the finished product cannot meet the actual demand and the production process is backward, so as to promote further development, low production cost and wear resistance high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

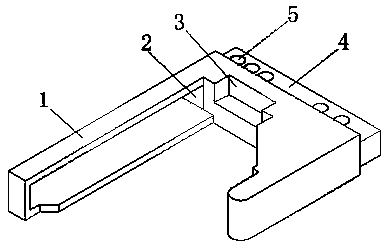

[0032] Embodiment 1: see figure 1 :

[0033] A knitting machine crossbeam and its production process, comprising a crossbeam body 1, a first groove 2 is opened on the left side of the inner cavity of the crossbeam body 1, a second groove 3 is opened on the top of the crossbeam body 1, and the rear side of the crossbeam body 1 The convex plate 4 is fixedly connected, and the top of the convex plate 4 is provided with fixing holes 5, and the number of the fixing holes 5 is five.

[0034] Among the present invention: the production formula of crossbeam of knitting machine is as follows:

[0035] Epoxy resin 67%;

[0036] Cobalt isooctanoate accelerator 1%;

[0037] Methyl ethyl ketone peroxide curing agent 2%;

[0038] Glass fiber 10%;

[0039] Polyurethane glue 5%;

[0040] Dibutyl phthalate 10%;

[0041] Ethylenediamine 5%.

[0042] Among the present invention: the production steps of knitting machine beam are as follows:

[0043] Step 1: Mold finishing; after cleaning...

Embodiment 2

[0051] Embodiment 2: see figure 1 :

[0052] A knitting machine crossbeam and its production process, comprising a crossbeam body 1, a first groove 2 is opened on the left side of the inner cavity of the crossbeam body 1, a second groove 3 is opened on the top of the crossbeam body 1, and the rear side of the crossbeam body 1 The convex plate 4 is fixedly connected, and the top of the convex plate 4 is provided with fixing holes 5, and the number of the fixing holes 5 is five.

[0053] Among the present invention: the production formula of crossbeam of knitting machine is as follows:

[0054] Epoxy resin 65%;

[0055] Cobalt isooctanoate accelerator 2%;

[0056] Methyl ethyl ketone peroxide curing agent 2%;

[0057] Glass fiber 12%;

[0058] Polyurethane glue 5%;

[0059] Dibutyl phthalate 10%;

[0060] Ethylenediamine 3%.

[0061] Among the present invention: the production steps of knitting machine beam are as follows:

[0062] Step 1: Mold finishing; after cleaning...

Embodiment 3

[0070] Embodiment 3: see figure 1 :

[0071] A knitting machine crossbeam and its production process, comprising a crossbeam body 1, a first groove 2 is opened on the left side of the inner cavity of the crossbeam body 1, a second groove 3 is opened on the top of the crossbeam body 1, and the rear side of the crossbeam body 1 The convex plate 4 is fixedly connected, and the top of the convex plate 4 is provided with fixing holes 5, and the number of the fixing holes 5 is five.

[0072] Among the present invention: the production formula of crossbeam of knitting machine is as follows:

[0073] Epoxy resin 66%;

[0074] Cobalt isooctanoate accelerator 1%;

[0075] Methyl ethyl ketone peroxide curing agent 3%;

[0076] Glass fiber 12%;

[0077] Polyurethane glue 5%;

[0078] Dibutyl phthalate 10%;

[0079] Ethylenediamine 3%.

[0080] Among the present invention: the production steps of knitting machine beam are as follows:

[0081] Step 1: Mold finishing; after cleaning...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com