Method and device for rapid detection of cleanliness of mechanical parts

A detection device and a technology of mechanical parts, which are applied in the preparation of test samples and weighing by removing certain components, can solve the problems of difficult online detection in time, time-consuming, troublesome detection methods, etc., and achieve simple structure and high efficiency. The effect of precision and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] like Figure 4 The gear 26 of a certain specification is measured directly with a general electronic referred to as a precision of 0.01 g. The gear 26 before cleaning the gear 26 is placed in a normal electronic referred to in the precision of 0.01 g, and the quality before reading it is stabilized, and the quality prior to the cleaning is stabilized, and it is ΔM1; then the above-mentioned gear 26 is cleaned, dried In the original state, the re-placing accuracy is 0.01G, and the quality of the cleaning is read after the number of copies is stabilized, and the weight difference of the gear 26 is ΔX1 = ΔM1- ΔM2, so repeatedly, the average value of the weight difference is the cleaning degree of the cleaning of the gear 26 of the specification. Because the gear is not required to clean the cleanliness, it can be measured directly with ordinary electronics referred to in the range and accuracy, to demonstrate the rapid detection of the rapid detection of the mechanical parts cl...

Embodiment 2

[0037] like Figure 5 , The ordinary triangular horizontal measuring device is constructed by the left lever arm 18, the right lever arm 19, the left weighing disk 17, the right scales 20, and the precision electron is integrated with 0.001 g of the precision electron, and the main seat 22 and the triangular bracket 25 are commonly constructed. The left lever arm 18 and the right lever arm 19 are located on both sides of the triangular bracket 25, and the left lever arm 18 is suspended a left scales 17, and the right lever arm 19 is hoverted to hang a right scale plate 20, precision electron with accuracy is 0.001G. Located below the left scales 17, the bottom seat 22 is located below the right scale plate. The piston 16 before the same specification is cleaned is placed in the middle of the left scales 17, and the same specification is placed in the middle of the right scales 20, and the precision electron is said to be a precision electron number of 0.001 g of the precision of 0....

Embodiment 3

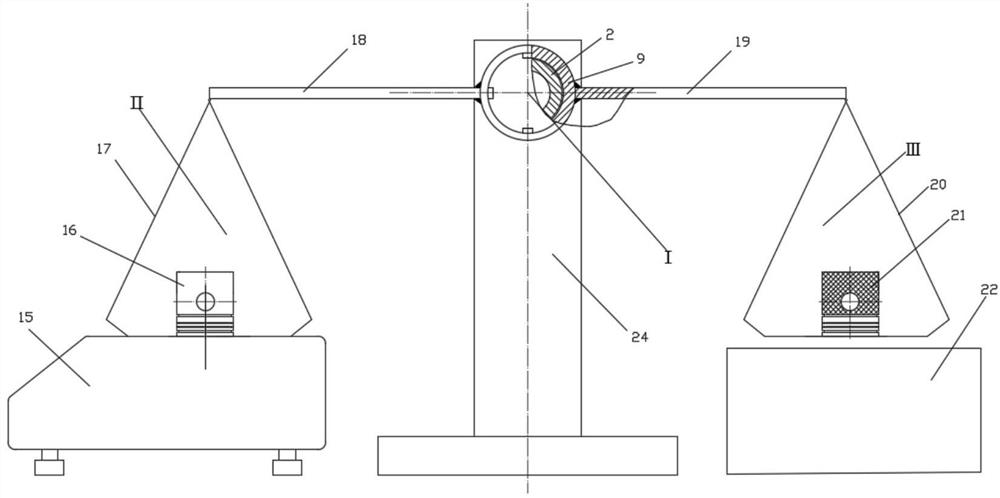

[0039] See figure 1A quick detection method and apparatus for mechanical components, detecting devices include balance, precision electronics, referred to, 20.001G, retrieval-sitting 22, and balance use air floture supporting balance, gas flotive support Tianping includes: gas Floating Handling System I, Sample Test Area II and Standard Part III III.

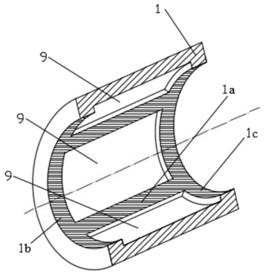

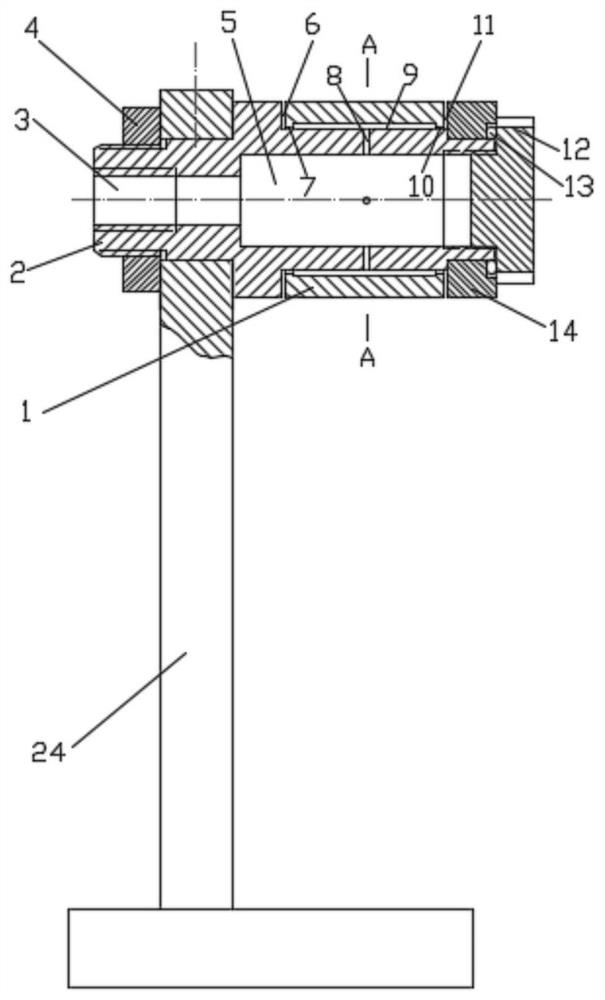

[0040] See figure 1 , figure 2 , Figure 3A and Figure 3B The gas float support system includes a gas flore bearing and a fixed bracket 24 including a gas float rotor 1, a gas floating stator 2, and a gear ring 14, and the air float stator 2 is fixedly mounted on the fixed bracket 24, air float The rotor 1 is set to the air floating stator 2, both of which are gaps; the air float stator 2 is a hollow structure, and the air float stator 2 is a compressed air interface 3, and the other end is sealed by the end cap 12, thereby forming a cavity 5; The gear ring 14 is set to one end of the air float stator 2 close to the end cover 12 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com