Method and device for quickly detecting cleanliness of mechanical part

A technology of mechanical parts and detection devices, which is applied in the field of rapid detection of cleanliness of mechanical parts, can solve the problems of difficult online and timely detection, time-consuming, troublesome detection methods, etc., and achieves the effects of simple structure, high precision and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] like Figure 4 , directly use an ordinary electronic scale 27 with an accuracy of 0.01g to measure the cleanliness of the gear 26 of a certain specification before and after cleaning. Put the gear 26 of a certain specification before cleaning into an ordinary electronic scale 27 with an accuracy of 0.01g, and read out its mass before cleaning after the reading is stable, and record it as Δm1; then take out the above-mentioned gear 26 for cleaning and drying To the original state, put it into an ordinary electronic scale 27 with an accuracy of 0.01g, read out the mass after the cleaning after the reading is stable, and record it as Δm2, and calculate the weight difference of the gear 26 before and after cleaning as Δx1=Δm1- Δm2, so repeated many times, the average value of the weight difference obtained is the cleanliness of the gear 26 of this specification. Because gears do not have high requirements on cleanliness, they can be directly measured with an ordinary elect...

Embodiment 2

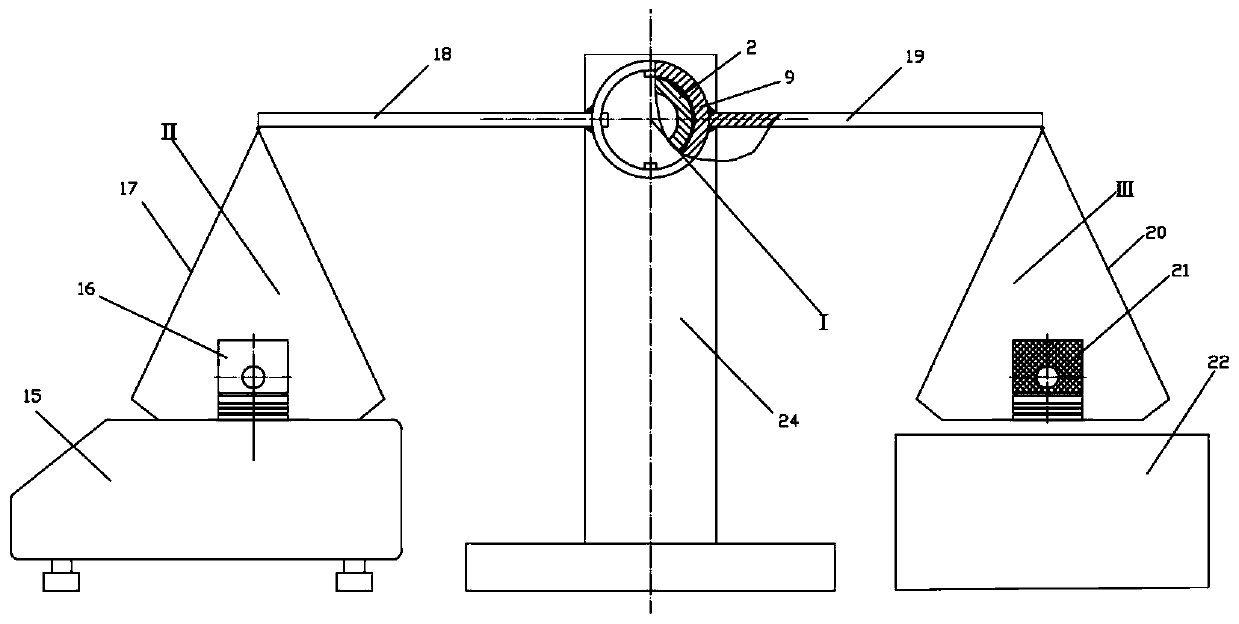

[0037] like Figure 5 , Common triangular balance measuring device is made up of left lever arm 18, right lever arm 19, left weighing pan 17, right weighing pan 20, the precision electronic scale 15 that precision is 0.001g, support base 22 and tripod 25 jointly. The left lever arm 18 and the right lever arm 19 are located on both sides of the tripod 25 respectively, a left weighing pan 17 is hung from the left end of the left lever arm 18, a right weighing pan 20 is hung from the right end of the right lever arm 19, and a precision electronic scale 15 with an accuracy of 0.001g It is located under the left weighing pan 17, and the supporting base 22 is located under the right weighing pan 20. Put the above-mentioned piston 16 of the same specification before cleaning into the middle of the left weighing pan 17, put the piston standard room 21 of the same specification into the middle of the right weighing pan 20, and read the reading of the precision electronic scale 15 with ...

Embodiment 3

[0039] see figure 1A method and device for quickly detecting the cleanliness of mechanical parts. The detection device includes a balance, a precision electronic scale 15 with an accuracy of 0.001 g, and a bottom seat 22. The balance adopts an air-floating supporting balance, and the air-floating supporting balance includes: Floating support system Ⅰ, sample detection area Ⅱ and standard part reference area Ⅲ.

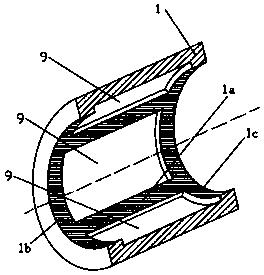

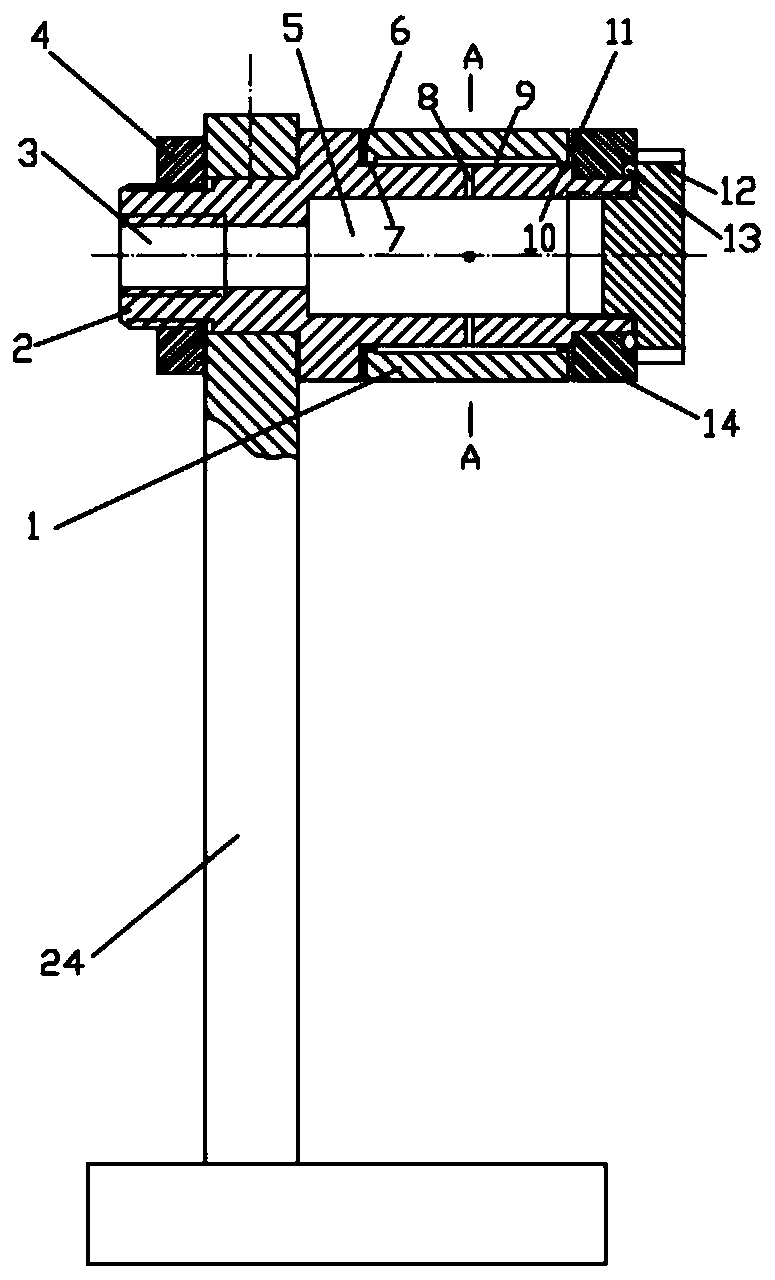

[0040] see figure 1 , figure 2 , Figure 3a and Figure 3b , the air bearing system includes an air bearing and a fixed bracket 24, the air bearing includes an air bearing rotor 1, an air bearing stator 2 and a retaining ring 14, the air bearing stator 2 is fixedly installed on the fixing bracket 24, and the air bearing The rotor 1 is sleeved on the air-floating stator 2, and the two are clearance fit; the air-floating stator 2 is a hollow structure, one end of the air-floating stator 2 is a compressed air interface 3, and the other end is sealed by an end cover 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com