Ceramic product sintering temperature testing method and ceramic product metal element precipitation amount testing method

A technology of sintering temperature and test method, applied in the field of ceramic products, can solve the problems of damage to ceramic products, complicated sintering temperature test method, and inability to detect sintering temperature, etc., and achieve the effect of simple test method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

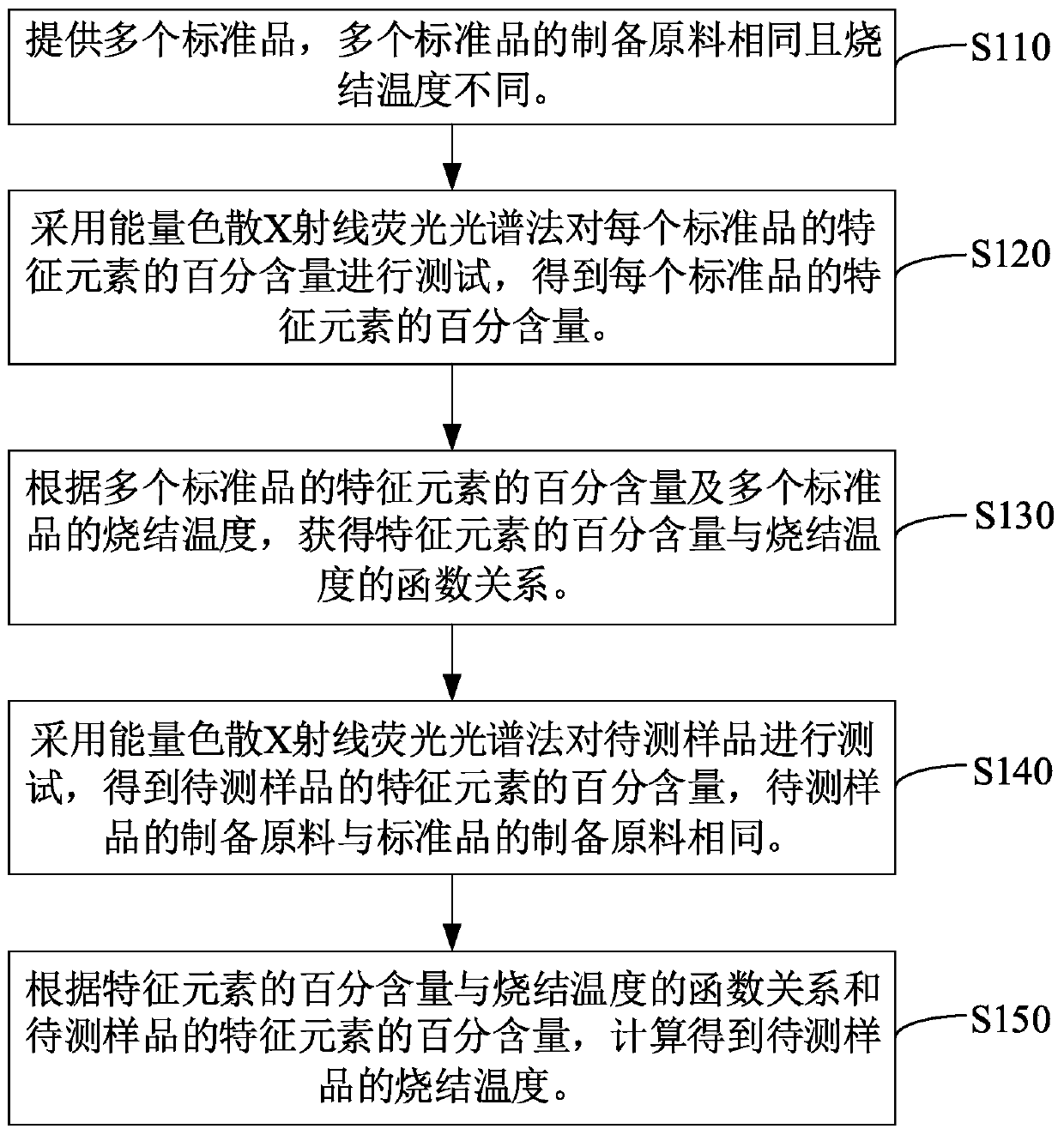

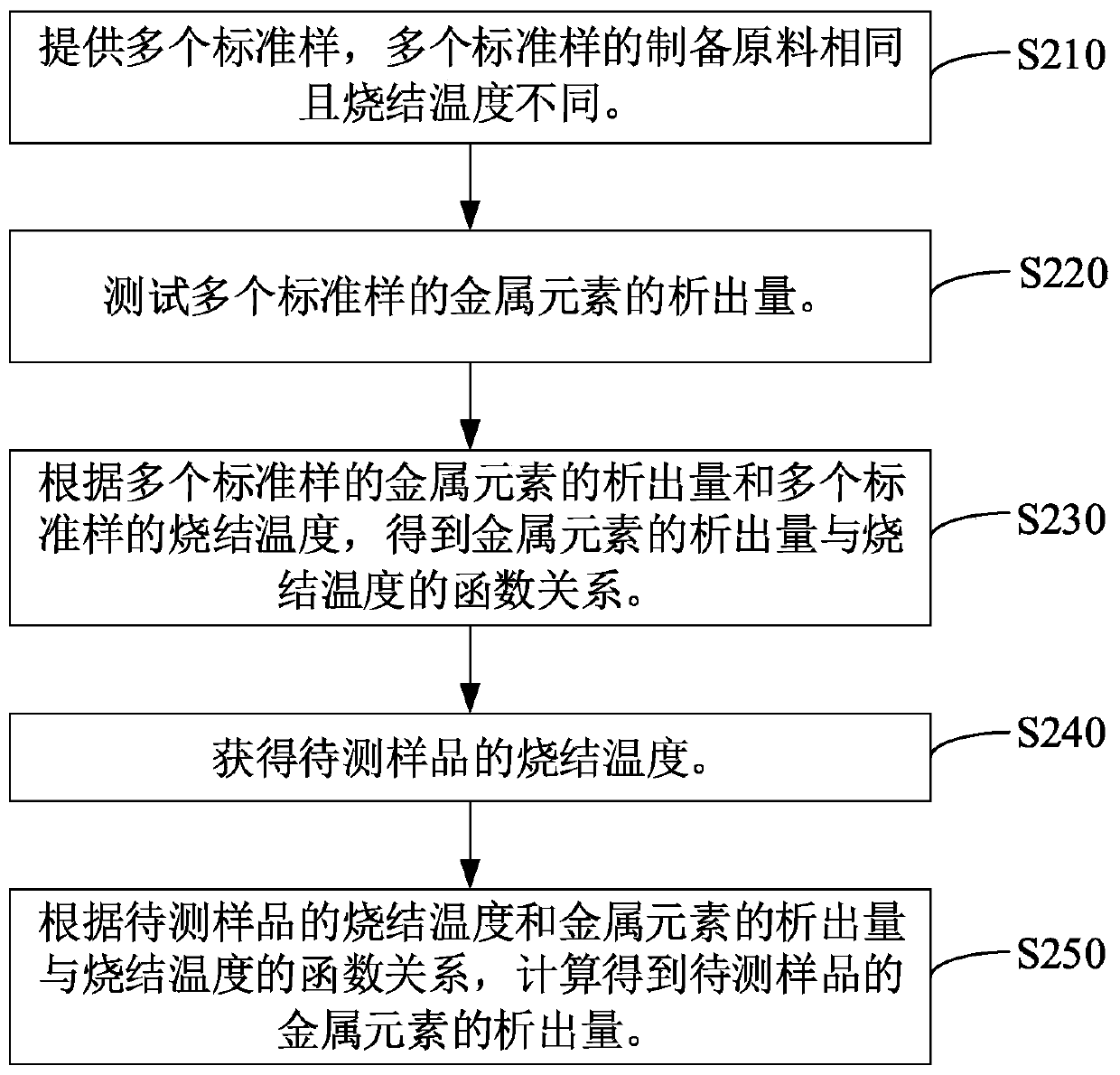

Method used

Image

Examples

preparation example Construction

[0052] Although the raw materials for the preparation of the above standard products are the same, they are sintered at different sintering temperatures. Due to the ignition loss effect in the high temperature sintering process, the percentage content of some elements will decrease. The greater the reduction, the different percentages of the characteristic elements in the resulting standard.

[0053] Based on the shrinkage effect of high-temperature firing, due to the volume reduction of ceramic products (taking purple sandware as an example, the firing shrinkage rate is about 3% to 10%), the higher the sintering temperature, the greater the firing shrinkage rate. Therefore, under the same test conditions of energy dispersive X-ray fluorescence spectrometry for ceramic products prepared at different sintering temperatures, the measured characteristic elements will have obvious differences and quantitative data that can be distinguished. In this embodiment Use this as the test ...

Embodiment 1

[0094] The specific process of the test method of the sintering temperature of the sample to be tested of embodiment 1 is as follows:

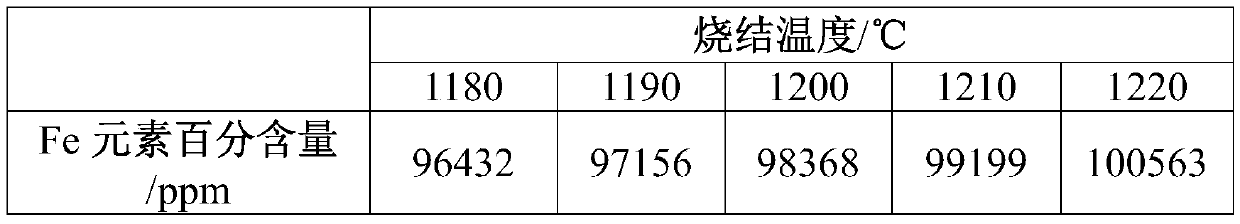

[0095] Taking the green (tender mud) at the bottom of the purple mud tank as an example, five groups of samples were made from 1180°C to 1220°C at 10°C, and each set of samples included 10 purple sand test pieces. It is fired at 1190°C, 1200°C, 1210°C and 1220°C for the same time, and then the percentage of characteristic elements of the purple sand test piece is tested by energy dispersive X-ray fluorescence spectrometry, and the percentage of characteristic elements of each group of samples is obtained The average value of the content is shown in Table 1 below. Then according to the percentage content of the characteristic element and the sintering temperature, the functional relationship between the percentage content of the characteristic element Fe and the sintering temperature is obtained: y=103.05x-25316, where x represents the sinterin...

Embodiment 2

[0101] The specific process of the test method of the sintering temperature of the sample to be tested of embodiment 2 is as follows:

[0102] Taking the green mud of Jiani Mine in Qinglong Mountain as an example, the sintering temperature is generally around 1200°C to 1230°C, and 8 groups of samples with different sintering temperatures are fired at 1170°C to 1240°C. The sintering temperature of each group of samples is shown in Table 2 below . There are 10 samples in each group, and energy dispersive X-ray fluorescence spectrometry is used to obtain the percentage content of the characteristic elements of each sample in each group of samples, and calculate the average of the percentage contents of the characteristic elements of each group of samples Values, the data table of the sintering temperature and the percentage content of the characteristic elements shown in Table 2 below is obtained.

[0103] According to the percentage content of characteristic element shown in ta...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap