A method of making a Schottky

A manufacturing method, dry etching technology, applied in the direction of final product manufacturing, sustainable manufacturing/processing, semiconductor/solid-state device manufacturing, etc., can solve problems such as high processing costs, affecting product profitability, and non-contribution, and achieve improvement Productivity, reduction of overlay requirements, and improvement of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The present invention will be further described below with reference to the accompanying drawings and specific embodiments.

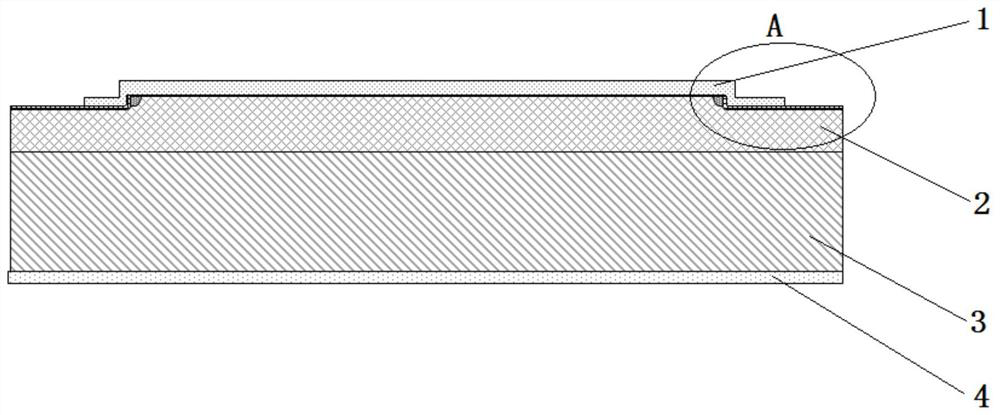

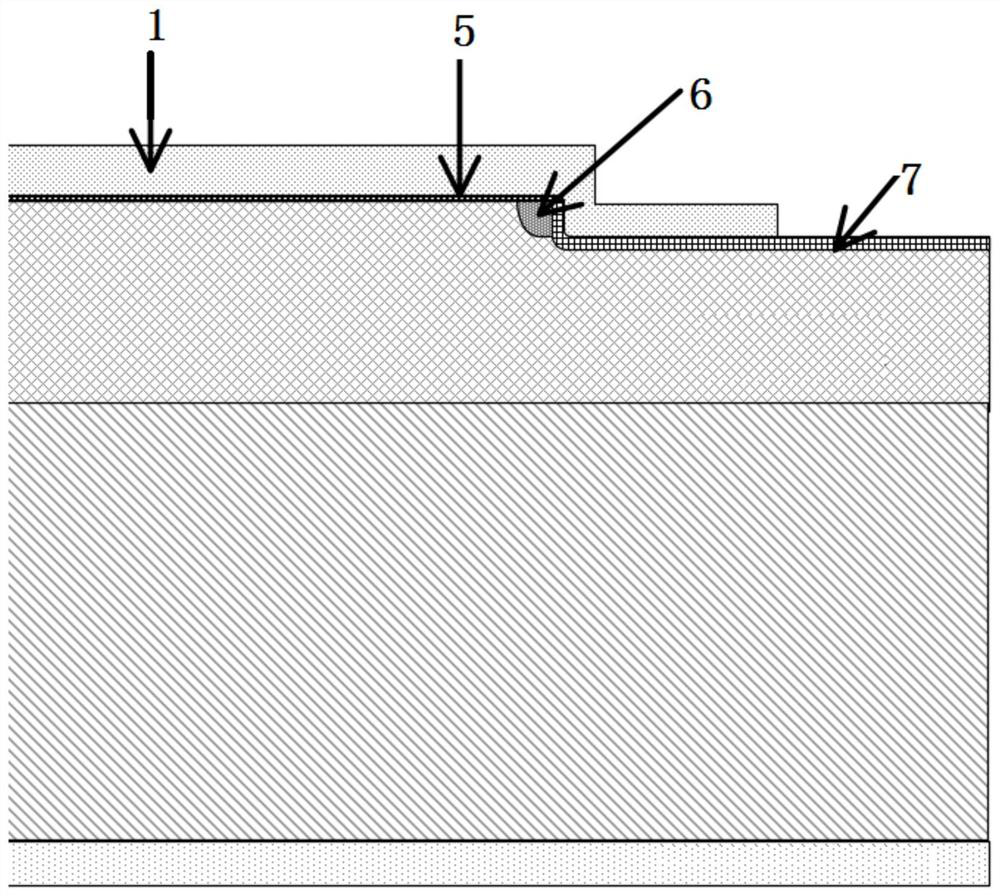

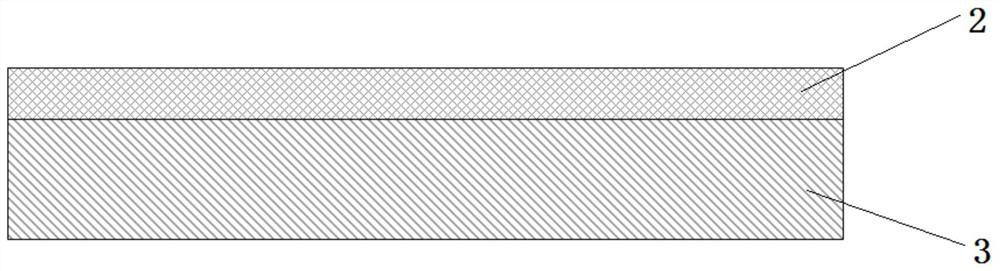

[0055] figure 1 and 2 A schematic structural diagram of an embodiment of the present invention is shown, and the structure of this embodiment is specifically shown. This embodiment relates to a Schottky manufacturing method, which is used to prepare the structure of a Schottky device. figure 1 and 2 The structure of the Schottky device prepared by this method is shown. The field limiting ring, hole self-alignment technology and LOCOS process are used to prepare, and the self-alignment of the barrier region and the field limiting ring is realized by two photolithography. Reduce the processing cost and equipment occupation, reduce the overlay requirements of the control layer and the field limit ring, especially the field limit ring structure with small line width, reduce the number of lithography layers processed, reduce the processing cost, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com