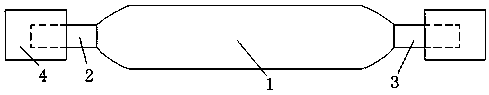

Air conditioner silencer unplugging machine

A muffler and air-conditioning technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of low efficiency and high labor intensity of workers, and achieve the effect of reducing labor intensity and high plugging efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

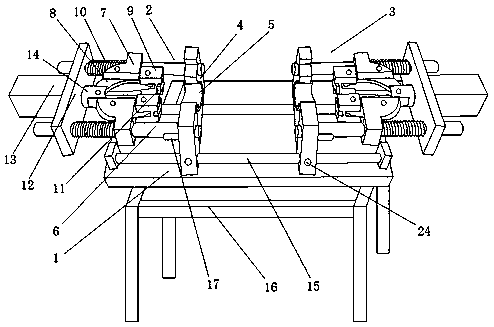

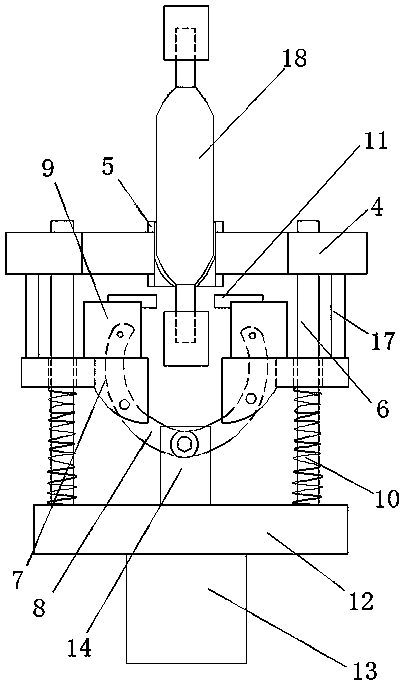

[0021] An embodiment of an air conditioner muffler of the present invention, such as Figure 2-Figure 6 As shown, including a bottom plate 1, a first plugging mechanism 2 and a second plugging mechanism 3 are symmetrically arranged on the bottom plate 1, and each plugging mechanism includes a vertical plate 4 arranged on the bottom plate 1, and each vertical plate 4 is provided with The supporting structure for placing the end of the muffler 18 and limiting it in the axial direction, the first plugging mechanism and the second plugging mechanism have the same structure. The support structure includes a support plate 5 adapted to the end of the muffler. The support plate 5 is an arc-shaped support plate with an upward opening. bit silencer. Two guide rods 6 are arranged horizontally at intervals on each vertical plate 4, and mounting blocks 7 are arranged for guiding movement on each guiding rod 6, and connecting arms are hinged on each mounting block 7, and each connecting ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com