Blank cutting device for sock processing

A cutting device and blank technology, which are applied in the cutting of textile materials, metal processing, textiles and papermaking, etc., can solve the problems of easy wrinkling, low work efficiency, and impact on work progress when laying fabrics, so as to be conducive to popularization and use and work efficiency. High, trouble-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

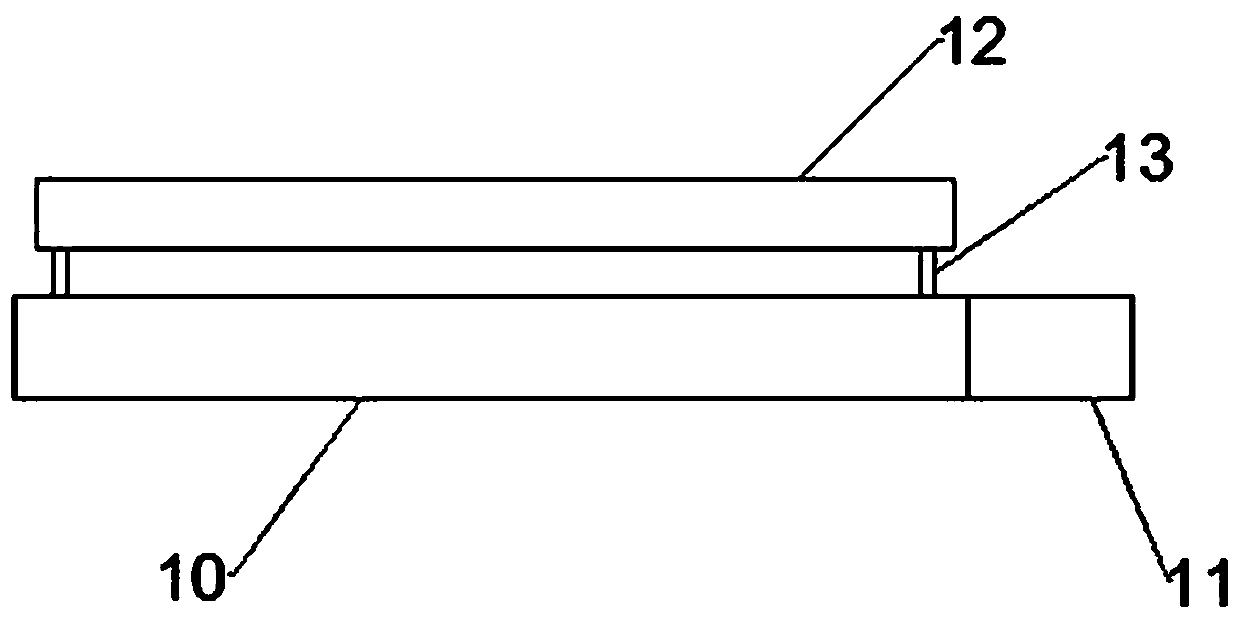

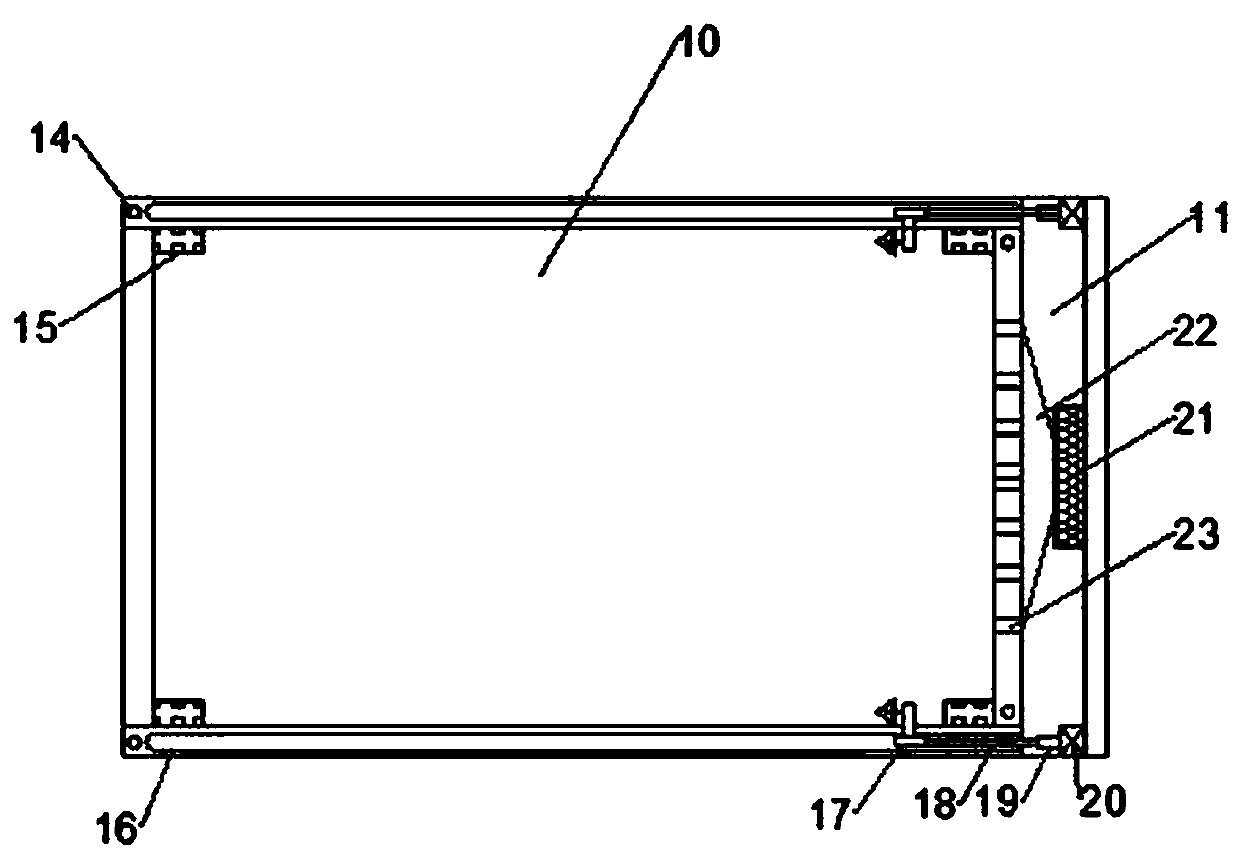

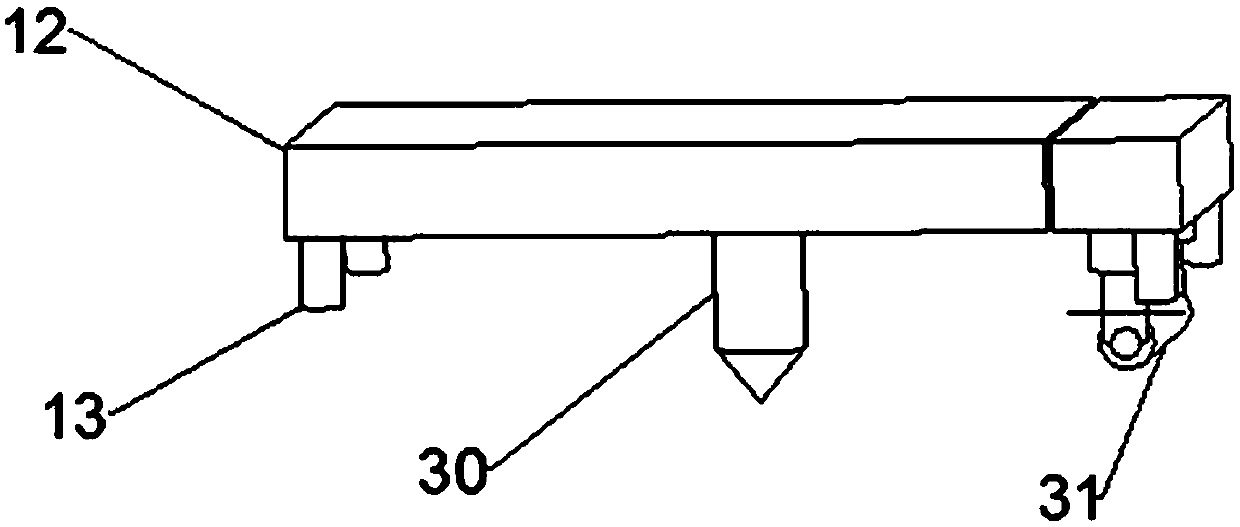

[0019] see Figure 1-5 , a blank cutting device for socks processing, comprising a cutting table 10, a control room box 11, a cutting frame 12 and a cutting knife 30; the control room box 11 is arranged on the right side of the cutting table 10, and the four corners of the bottom end of the cutting frame 12 are fixed Threaded rods 13 are installed, and the four corners of the cutting table 10 corresponding to the threaded rods 13 are provided with four groups of threaded grooves 14, and the threaded rods 13 and the threaded grooves 14 are threaded, so that the cutting frame 12 is installed on the upper side of the cutting table 10 . The lower side of the cutting frame 12 is provided with a cutting knife 30, and the sock blank inside the cutting table 10 is cut by the cutting knife 30. The bottom on the right side of the cutting frame 12 is provided with a pressing roller 31, which is used to press and hold the sock blank placed on the surface of the cutting table 10 to preven...

Embodiment 2

[0022] On the basis of Embodiment 1, a fan 21 is provided in the middle of the control room box 11, the left output end of the fan 21 is connected with an air chamber 22, and the outside of the air chamber 22 is connected with several sets of exhaust holes 23, The wind generated by the blower fan 21 is input into the air bin 22, and then the sock blanks in cutting are blown, thereby removing the dust and other impurity pollution produced by the sock blanks during cutting.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com