Heat insulation headlining and heat insulation system for vehicle

A technology for automobiles and canopies, which is applied to vehicle components, superstructure sub-assemblies, coatings, etc., can solve the problems of poor thermal insulation performance of thermal insulation canopies, and achieve the effect of reducing heat and simplifying the structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

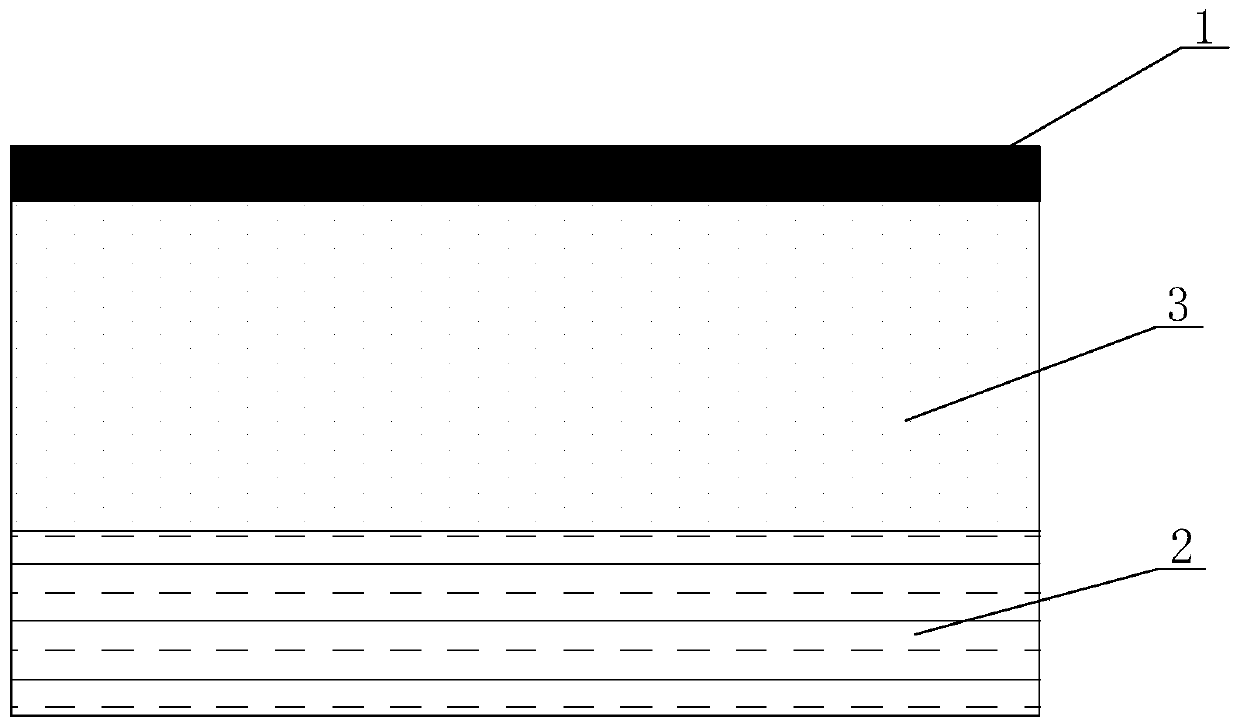

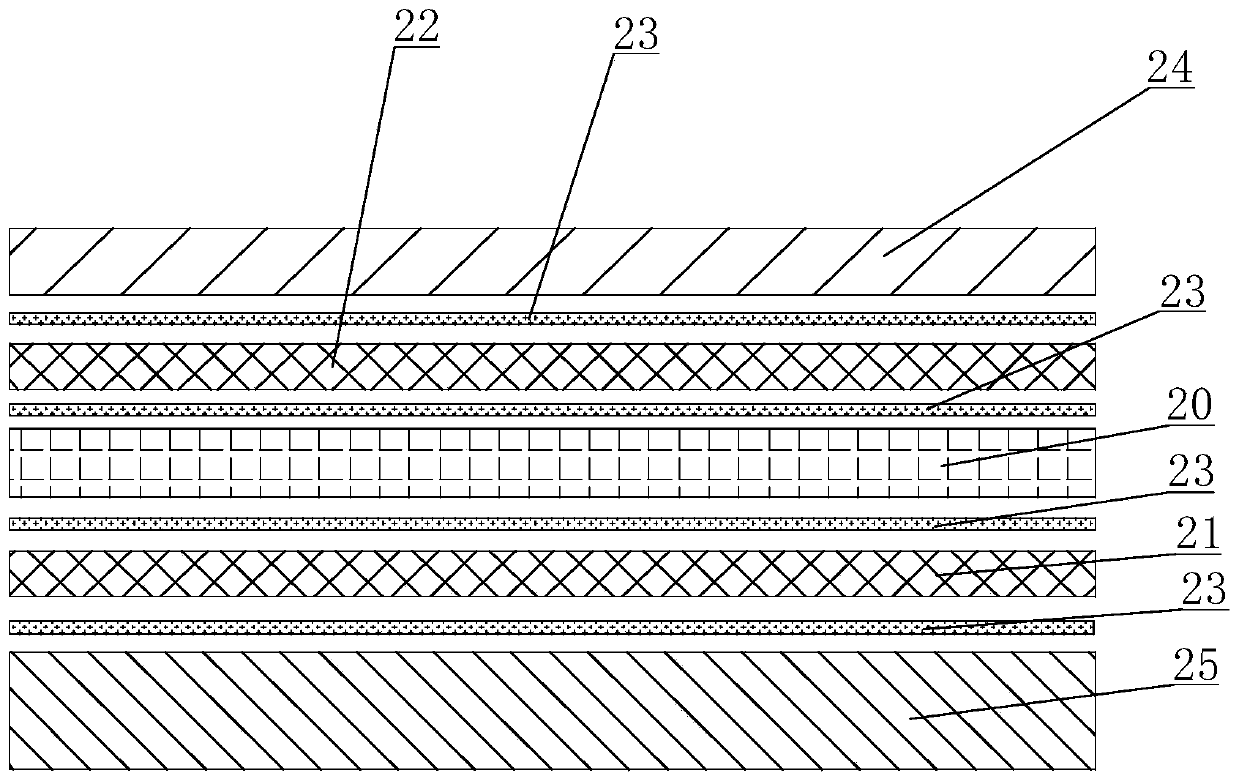

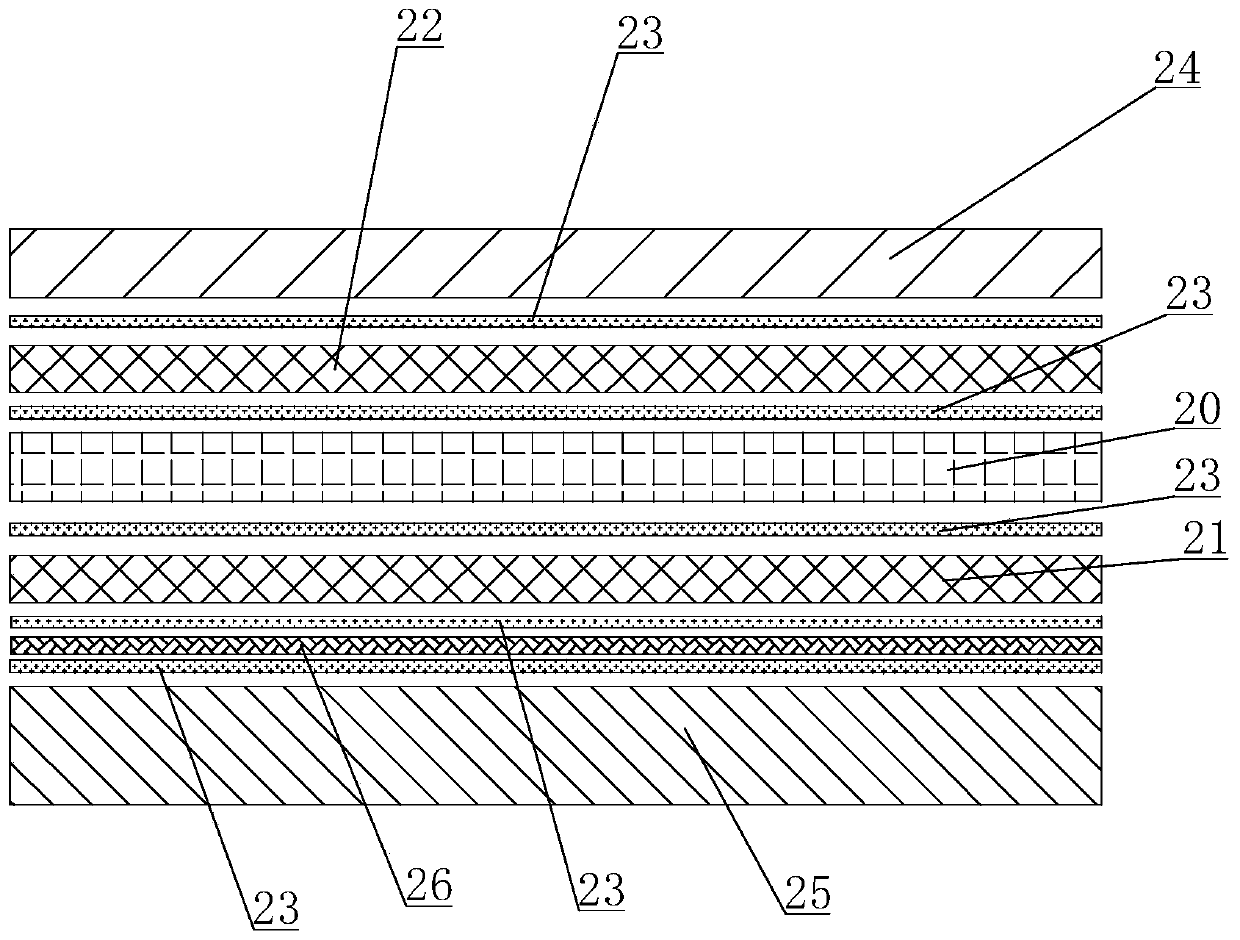

[0025] see figure 1 and figure 2 As shown, in this embodiment, a kind of heat insulation roof for automobiles, the heat insulation roof is a wet one-step roof structure, which includes a base material layer 20, the base material layer 20 adopts PU semi-rigid foam board, the thickness 8㎜~10㎜, preferably 8㎜, 9㎜ and 10㎜; the weight per cubic meter is 22kg~32kg, preferably 22kg, 26kg, 30kg and 32kg; the substrate layer 20 is close to the interior of the car The first reinforcement layer 21 is provided on the surface through the adhesive layer 23, and the first reinforcement layer 21 adopts a glass fiber board, and its weight per square meter is 70g to 200g, preferably 70g, 100g, 130g, 160g and 200g; The layer 20 is provided with a second reinforcement layer 22 on the surface outside the car compartme...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com