Method for manufacturing screen printing plate

A production method and screen technology, which are used in printing plate preparation, screen printing machines, printing, etc., can solve the problems of uncontrollable thickness, affecting the printing performance of printing patterns, and uneven coating of photosensitive adhesives.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

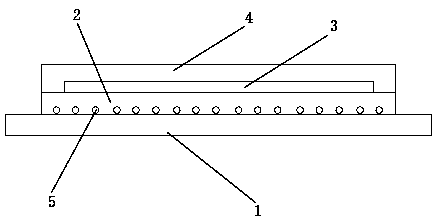

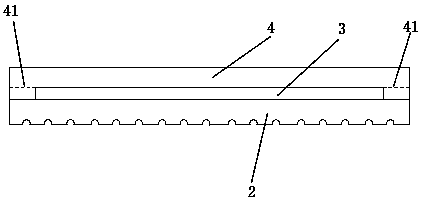

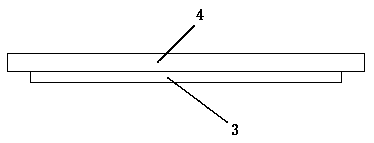

[0024] The content of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0025] like Figures 1 to 4 Shown, a kind of screen making method, the steps are as follows:

[0026] S1. Wire mesh weaving: Weave multiple metal wefts and multiple metal warps in an up-and-down staggered manner to form a mesh; the metal warps and metal wefts are made of stainless steel, tungsten steel, titanium, aluminum, copper One of nickel and nickel, the metal warp and metal weft made of aluminum can be selected in this embodiment.

[0027] S2. Stretching the net: the metal weft and the weft are stretched with tension and fixed on a screen frame to form a screen.

[0028] S3, prefabricated photosensitive film: choose a base film 1, evenly sprinkle activated alumina powder 5 on the base film 1, spray the first layer of photosensitive adhesive 2 on the base film sprinkled with activated alumina powder 5; The middle position of layer photo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com