Smart garbage bin and garbage packing method with vacuuming and drainage functions

A garbage can, intelligent technology, applied in the direction of garbage cans, garbage collection, household appliances, etc., can solve the problems of low penetration rate, high sales price, complex structure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

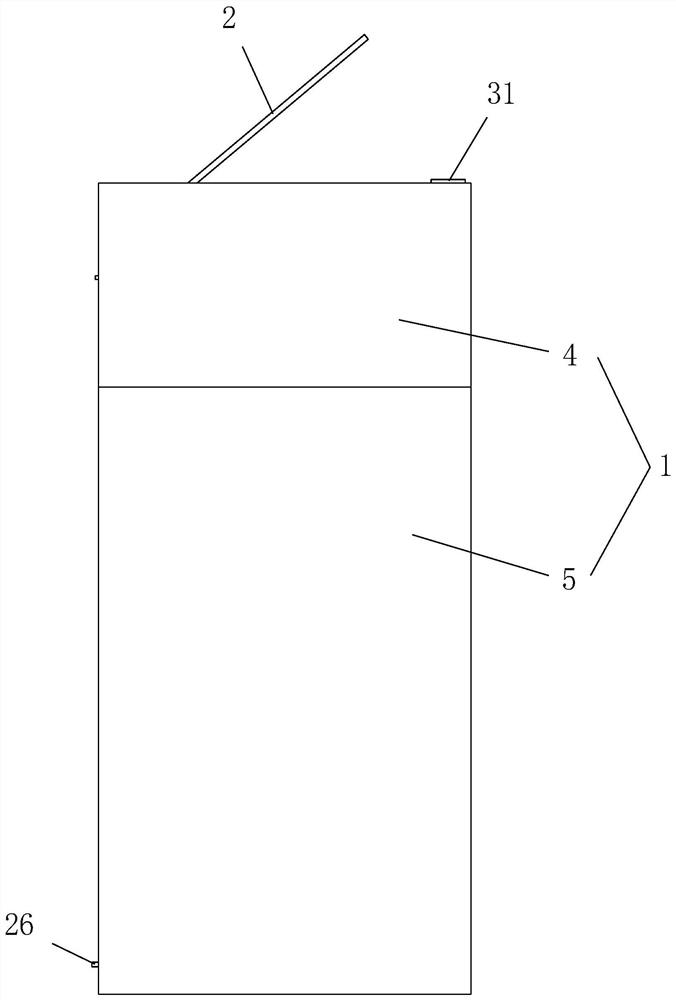

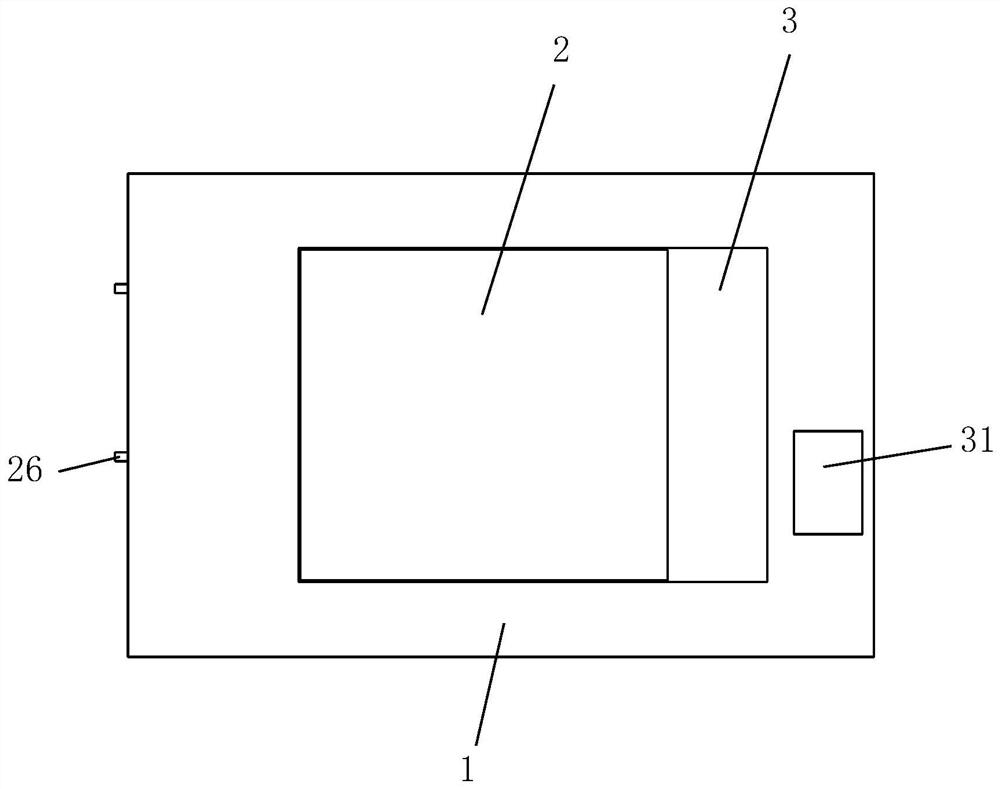

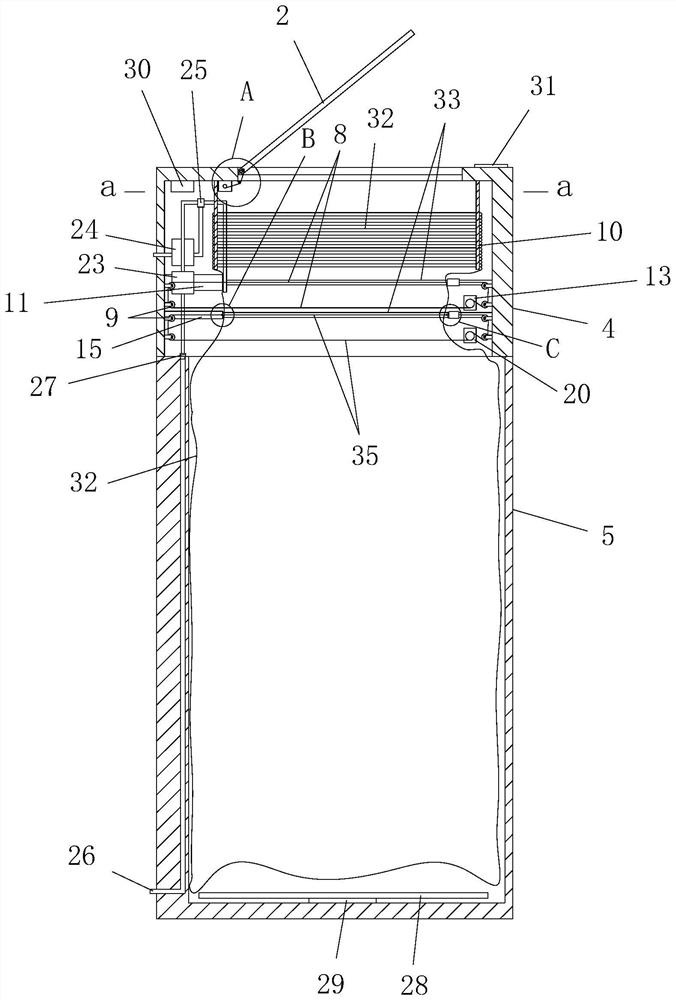

[0065] Such as figure 1 and Figure 4 As shown, this embodiment provides an intelligent trash can, which includes a barrel body 1 and a barrel cover 2 , and the barrel cover 2 is set on the upper opening 3 of the barrel body 1 . The cross section of the barrel body 1 can be circular, square, or other shapes, which are not limited. In this embodiment, a square is taken as an example. The bucket body 1 includes an upper casing 4 and a lower casing 5, the inside of the upper casing 4 is provided with a drive motor 6 that is in transmission connection with the bung cover 2, and the bung cover 2 and the upper casing 4 are provided with There is a torsion spring 7, and the opening of the bung 2 is realized by the reverse rotation of the driving motor 6 and the torsional force of the torsion spring 7, and the closing of the bung 2 is realized by the forward rotation of the driving motor 6. The drive motor 6 realizes the linkage with the bung 2 through the third traction rope 36 and...

Embodiment 2

[0080] This embodiment provides a method for packing garbage with a vacuum function, which is applied to the smart trash can in Embodiment 1, and specifically includes the following steps:

[0081] It also includes a control circuit board installed in the barrel, and a distance sensor installed on the inner surface of the barrel cover;

[0082] S1: The control circuit board makes the driving motor reverse, the lid is opened, and garbage is put in; after 10 seconds, the control circuit board makes the driving motor rotate forward, and the lid is closed;

[0083] S2: If the weighing component detects that the weight of the garbage is greater than the set weight, or the distance sensor detects that the distance between the garbage and the lid is less than the set distance, then the control circuit board controls the bag clamping mechanism, sealing and cutting mechanism and bag filling mechanism to perform packing operations ;

[0084] S21: The two first servo motors rotate forwa...

Embodiment 3

[0094] This embodiment provides a garbage packing method with a drainage function, which is applied to the smart trash can in Embodiment 1, and specifically includes the following steps:

[0095] It also includes a control circuit board installed in the barrel, and a distance sensor installed on the inner surface of the barrel cover;

[0096] S1: The control circuit board makes the driving motor reverse, the lid is opened, and garbage is put in; after 10 seconds, the control circuit board makes the driving motor rotate forward, and the lid is closed;

[0097] S2: If the weighing component detects that the weight of the garbage is greater than the set weight, or the distance sensor detects that the distance between the garbage and the lid is less than the set distance, then the control circuit board controls the bag clamping mechanism, sealing and cutting mechanism and bag filling mechanism to perform packing operations ;

[0098] S21: The two first servo motors rotate forward...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com