Blockage removing pipeline and blockage removing method for double-sleeve long-distance pneumatic material conveying

A pneumatic conveying and long-distance technology, which is applied in the direction of conveying bulk materials, conveyors, transportation and packaging, etc., can solve the problems of high investment and annual operating costs, a large number of air compressors, and poor economy, so as to avoid the waste of compressed air , high degree of automation and short blowing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

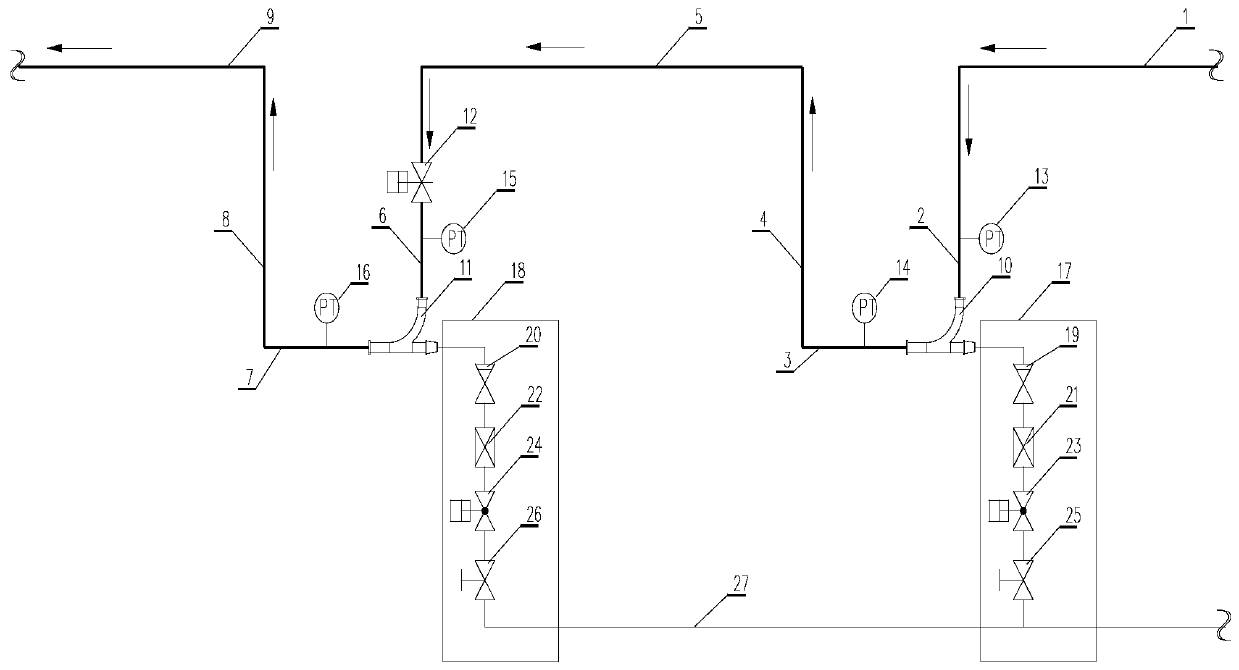

[0027] see figure 1 , taking two groups of U-shaped pipeline segments as an example, the anti-blocking pipeline for long-distance pneumatic conveying of materials with double sleeves in the present invention includes a first wear-resistant tee joint 10, a second wear-resistant tee joint 11 and a first wear-resistant tee joint 11. The pressure transmitter 13, the second pressure transmitter 14, the third pressure transmitter 15, the fourth pressure transmitter 16, the first horizontal section 1 of the first U-shaped arrangement of the long-distance double-pipe conveying material pipeline and the third horizontal section 5 through the first descending section 2, the second horizontal section 3 and the first ascending section 4; the third horizontal section 5 and the second U-shaped arrangement of the long-distance double casing conveying materia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com