A kind of preparation method of high-purity calcium hydroxide

A calcium hydroxide, high-purity technology, applied in the field of preparation of high-purity calcium hydroxide, can solve the problems of complex calcium hydroxide process operation and low efficiency, and achieve the effects of improving resource utilization efficiency, reducing pollution, and improving dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

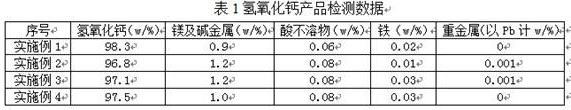

Examples

Embodiment 1

[0019] A kind of preparation method of high-purity calcium hydroxide, it specifically comprises the steps:

[0020] (1) Dry carbide slag under ultrasonic conditions for 1 hour, and then pass through a 250-mesh sieve to obtain carbide slag pretreatment; the ultrasonic drying is carried out at an ultrasonic frequency of 40kHz and a temperature of 50°C;

[0021] (2) Stir and mix the calcium carbide slag pretreated product obtained in step (1) and deionized water at a ratio of 1:12 by weight for 45 minutes to obtain a mixed solution, and then mix the mixed solution at a stirring speed of 400r / min. The liquid and the organic extractant are mixed according to the weight ratio of 10:2, extracted at 60°C for 2 hours, then left to stand for 20 minutes, and the organic phase is separated and removed by suction filtration to obtain a solid; the organic solvent is ethanediol It is obtained by mixing alcohol and tributyl phosphate according to the ratio of 4:1 by weight;

[0022] (3) Mix ...

Embodiment 2

[0024] A kind of preparation method of high-purity calcium hydroxide, it specifically comprises the steps:

[0025] (1) Dry carbide slag under ultrasonic conditions for 1.5 hours, and then pass through a 200-mesh sieve to obtain carbide slag pretreatment; the ultrasonic drying is carried out at an ultrasonic frequency of 30kHz and a temperature of 40°C;

[0026] (2) Stir and mix the calcium carbide slag pretreated product obtained in step (1) and deionized water at a ratio of 1:10 by weight for 30 minutes to obtain a mixed solution, and then mix the mixture at a stirring speed of 300r / min Liquid and organic extractant were mixed according to the weight ratio of 10:1, extracted at 80°C for 1 hour, then left to stand for 30 minutes, separated and removed the organic phase, and suction filtered to obtain a solid; the organic solvent was ethylene glycol It is obtained by mixing alcohol and tributyl phosphate according to the ratio of 3:1 by weight;

[0027] (3) Mix the solid obta...

Embodiment 3

[0029] A kind of preparation method of high-purity calcium hydroxide, it specifically comprises the steps:

[0030] (1) Dry carbide slag under ultrasonic conditions for 2 hours, and then pass through a 300-mesh sieve to obtain carbide slag pretreatment; the ultrasonic drying is carried out at an ultrasonic frequency of 60kHz and a temperature of 60°C;

[0031] (2) Stir and mix the calcium carbide slag pretreated product obtained in step (1) and deionized water at a ratio of 1:15 by weight for 60 minutes to obtain a mixed solution, and then mix the mixture at a stirring speed of 500r / min The liquid and the organic extractant are mixed according to the weight ratio of 10:1.5, extracted at 50°C for 1.5 hours, then left to stand for 15 minutes, and the organic phase is separated and removed, followed by suction filtration to obtain a solid; the organic solvent is ethylene glycol It is obtained by mixing alcohol and tributyl phosphate according to the ratio of 2:1 by weight;

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com