A hydraulic unblocking tubing anchor

A technology for hydraulic unsealing and tubing anchors, which can be used in wellbore/well components, earth-moving drilling, etc., and can solve the problem of high operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

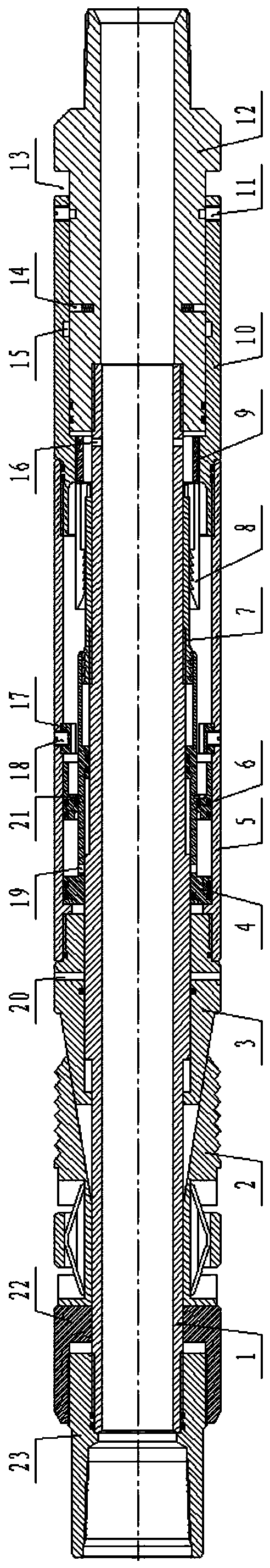

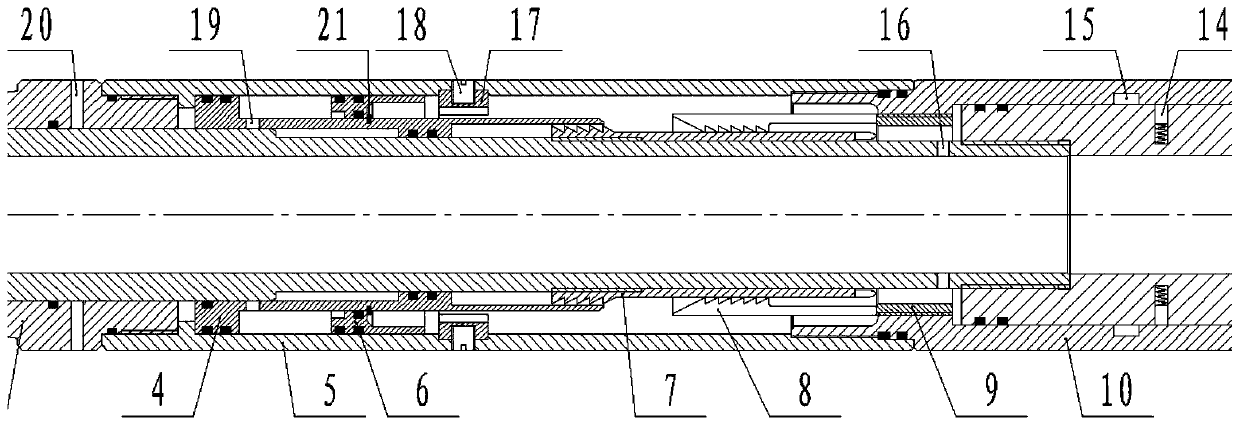

[0014] The present invention will be further described below in conjunction with accompanying drawing:

[0015] This embodiment includes an upper joint 23, a central pipe 1, slips 2 and a seating and unsealing mechanism. The above are common structures in the prior art, and will not be repeated here.

[0016] The upper joint 23 is connected to the upper end of the central tube 1 through threads, and the setting and unsealing mechanism includes a cone 3, a setting piston, a piston sleeve 5, a locking sleeve 9, a setting sleeve 10, a locking spring hanger 7, a lower joint 12 and a setting pin 11. The cone 3 is connected to the upper end of the piston sleeve 5 through threads, the setting piston is arranged in the piston sleeve 5, the piston sleeve 5 and the setting sleeve 10 are integrally connected through threads, and the locking sleeve 9 is connected to the setting sleeve 10 through threads, The lower joint 12 is screwed to the lower end of the central pipe 1, the setting sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com