External water circulation system having automatic control function and used for TBM and external water circulation method

A circulation system and external circulation technology, applied in household refrigeration equipment, cooling fluid circulation equipment, applications, etc., can solve the problems of difficult water return, large pressure drop of external water, difficult control of internal water temperature, etc., and achieve easy control and operation , Solve the effect that is difficult to control and cleverly designed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

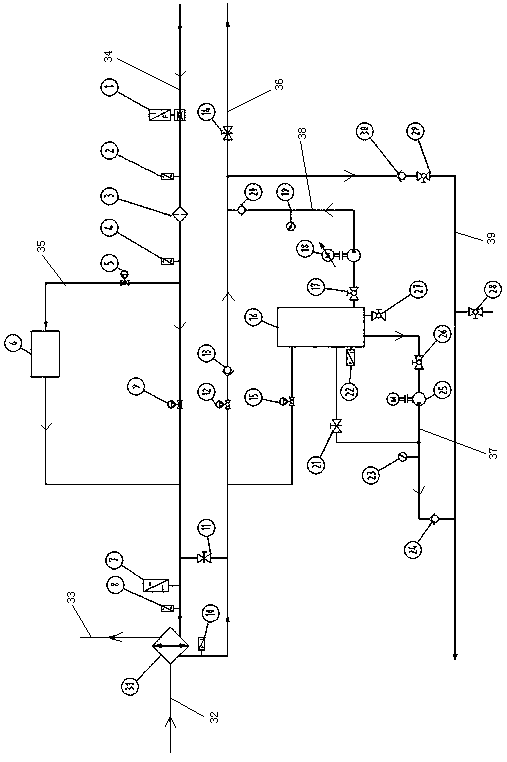

[0028] Embodiment 2, an external water circulation system with automatic control for TBM, the external circulation water outlet system includes a main water outlet pipeline 36, and a fourth pressure sensor 10, a third pneumatic The ball valve 12, the first one-way valve 13 and the first manual gate valve 14, the fourth pressure sensor 10 and the third pressure sensor 8 are located on both sides of the cooler respectively, and are used to monitor the pressure of the water inlet and outlet outside the cooler 31. When the two When the differential pressure exceeds the set value, the system will give an alarm, indicating that the cooler 31 is blocked. A warm water tank 16 is arranged in parallel between the third pneumatic ball valve 12 and the first manual gate valve 14, and a fourth pneumatic ball valve 15 is arranged on the water inlet pipeline of the warm water tank 16. water or not. The warm water tank 16 is provided with a first water outlet system and a second water outlet...

Embodiment 3

[0031] Example 3, such as figure 1 Shown, a kind of TBM uses the external water circulation method with the external water circulation system of automatic control, comprises the steps:

[0032] S1: When the tunnel distance is short, the flow rate of flow meter 1 is relatively large, and the return water distance does not exceed the maximum lift of the external water pump: the external water enters the cooler 31 through the main water inlet pipeline 34 to exchange heat with the internal circulating water, and the third pump is opened. The pneumatic ball valve 12 and the first manual gate valve 14 close the return water pump 18 and the third manual ball valve 29, and the external water returns directly under the action of the external water pump;

[0033] S2: When the tunnel distance is long, the flow rate of flow meter 1 is small, and the return water distance has exceeded the maximum lift of the external water pump, the external water enters the cooler 31 through the main wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com