Subway shallow-buried excavation tunnel underneath pass main traffic road pipe curtain construction method

A shallow buried excavation and tunnel technology, which is applied in tunnels, tunnel linings, underground chambers, etc., can solve problems such as pipeline deformation, surrounding rock collapse and roof fall, and small vault distance, so as to save construction time and reduce road surface settlement Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

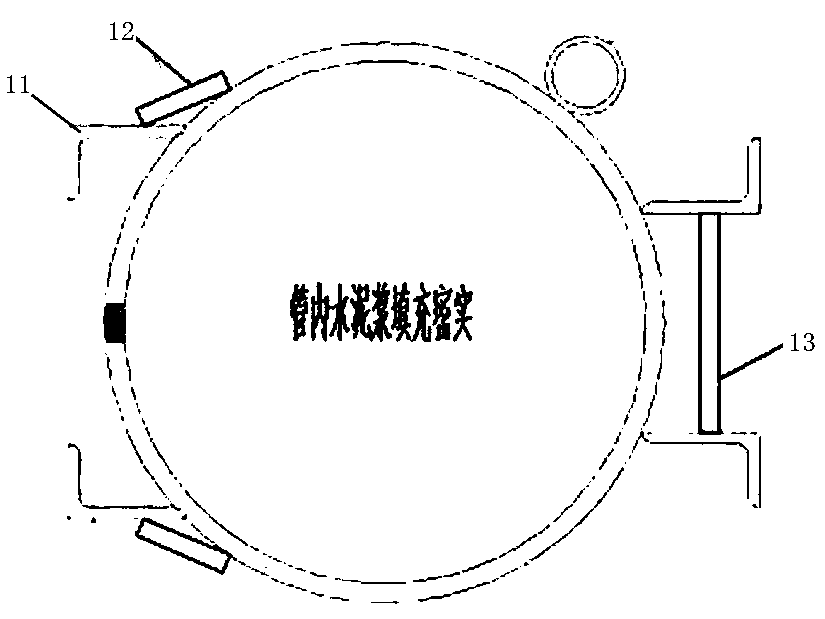

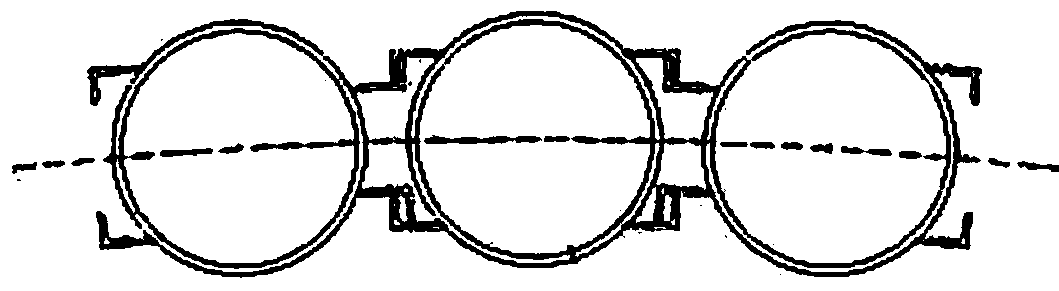

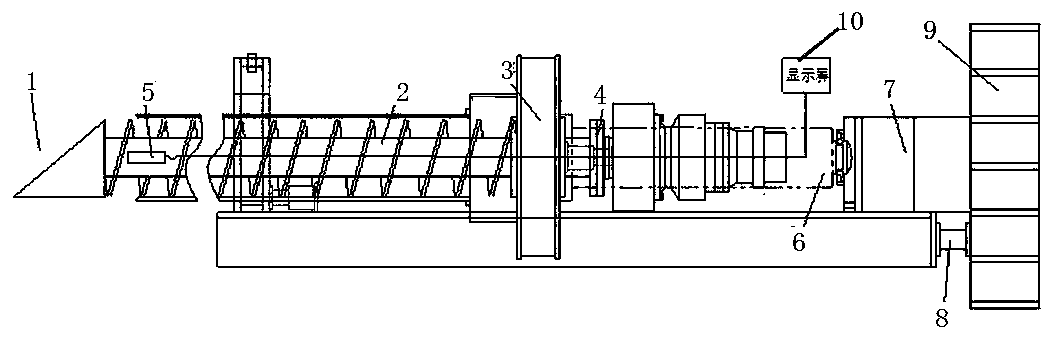

[0018] Such as figure 1 As shown in the figure, a subway shallow-buried underground excavation tunnel passes through the main traffic road pipe curtain construction method. The steps are as follows: 1) pipe installation: the outer side of the hollow steel pipe is welded with a locking structure, and several steel pipes are installed in sequence according to the direction of the locking structure; 2) Site leveling; 3) Measurement and stakeout; 4) Drilling pipe jacking: There is a coaxial auger rod 2 running through the middle of the steel pipe, and the center of the auger rod 2 is provided with a guiding measurement hole. The debris is discharged from the steel pipe through the auger drill pipe 2, and the jacking of the steel pipe and the unearthing of the screw are carried out at the same time, until the jacking of the steel pipe is in place, and each steel pipe is constructed in turn; 5) Grouting: use a double-liquid grouting pump for grouting , using cement slurry, the grout...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com