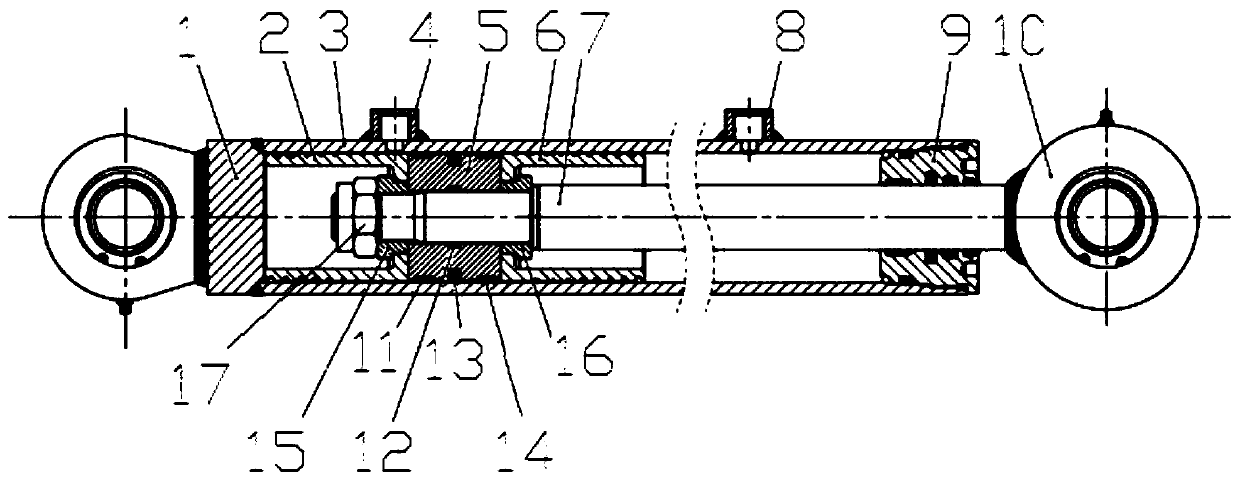

Lifting hydraulic oil cylinder buffering structure of garbage transfer truck

The technology of a garbage transfer vehicle and hydraulic cylinder is applied in the field of hydraulic machinery to achieve the effects of stable and reliable working performance, simplified structure, and simple buffer structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

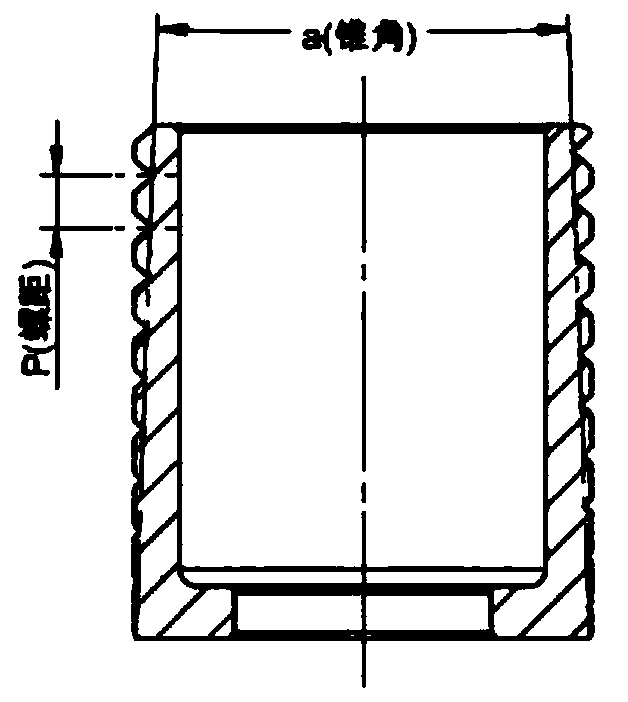

[0033] To further facilitate processing and assembly, the end of the piston rod 7 connected to the piston 5 is provided with a positioning step surface, and the end of the piston rod 7 is connected with a lock nut 17; both the piston 5 and the buffer piston have holes for the piston rod 7 to pass through. The piston 5 and the buffer piston are fixedly installed between the positioning step surface and the lock nut 17 through the lock nut 17; a piston bush is provided between the inner hole of the buffer piston and the outer wall of the piston rod 7. The inner diameter of the piston bushing is matched with the outer diameter of the piston rod 7 at the corresponding position, and the outer diameter of the piston bushing is matched with the inner hole diameter of the buffer piston at the corresponding position; for the same group of buffer pistons, only need to replace different specifications Piston bushings can be applied to piston rods 7 with different outer diameter specificati...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap