Visual positioning method in complex environment

A visual positioning and complex environment technology, applied in the field of visual positioning, can solve the problem of low positioning accuracy of robots and achieve the effect of improving positioning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0039] A visual positioning method in a complex environment, including long-distance left-right calibration and short-distance left-right calibration for the position of the robot;

[0040] The long-distance left-right calibration includes the following steps:

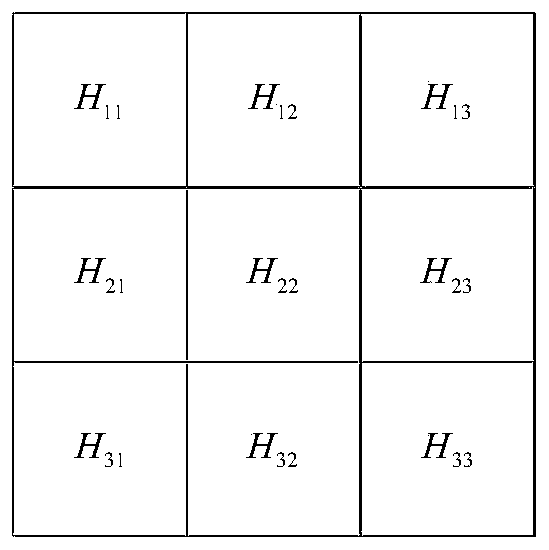

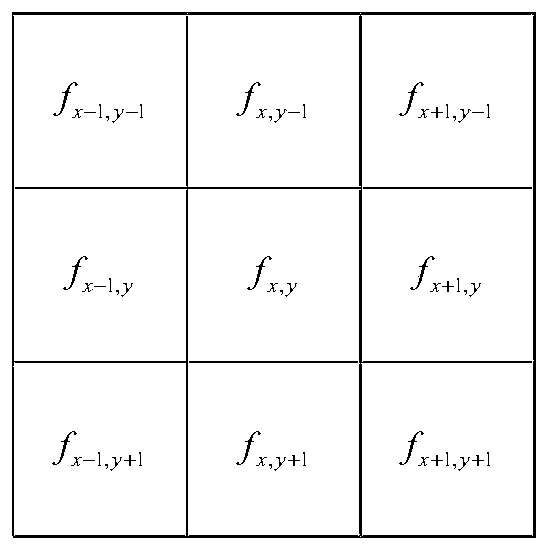

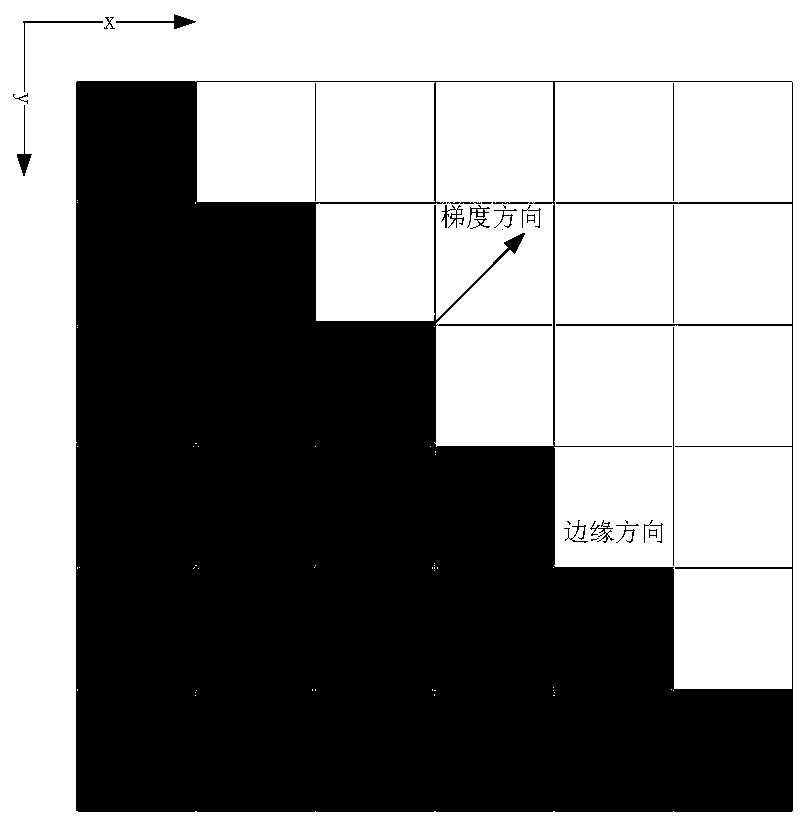

[0041] Target detection, three steps of graphic edge extraction, small outline removal and image morphology processing are performed on the image collected by the camera to obtain the original image in each outline area;

[0042] Graphical similarity comparison, use the image hash algorithm to compare the original image in each contour area with the surface template image, and find the contour with the highest similarity as the final matching result;

[0043] Calculate the position deviation, compare the final matching result with the template image to obtain the position deviation between the actual position of the robot and the position of the template;

[0044] The short-range left and right calibration includes: i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com