Household small pancake baking machine

A pancake and baking technology, which is applied in the field of household small pancake baking machines, can solve the problems of time-consuming, labor-intensive, and insufficient safety, and achieves the effects of compact and reliable structure, simple control, and small volume and space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

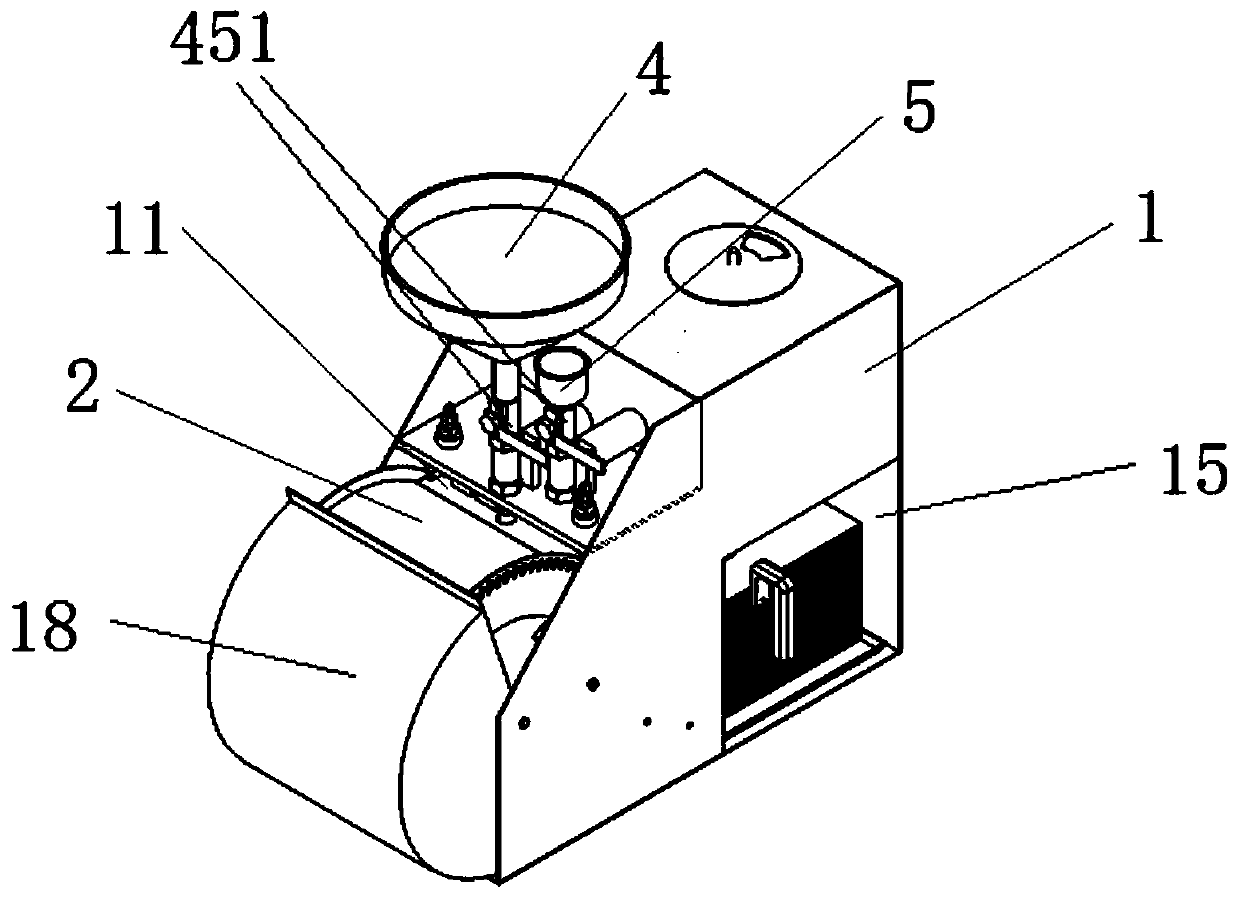

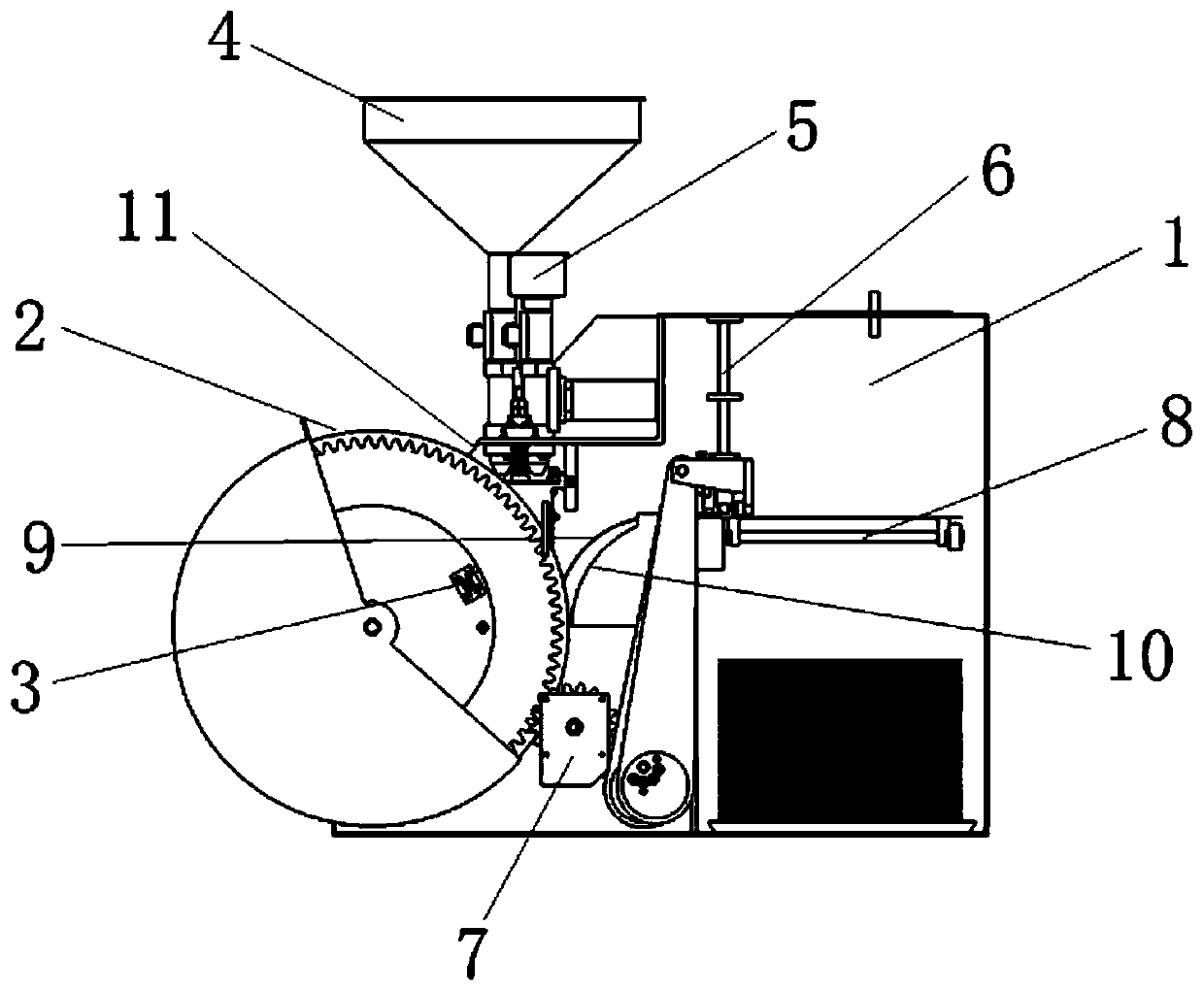

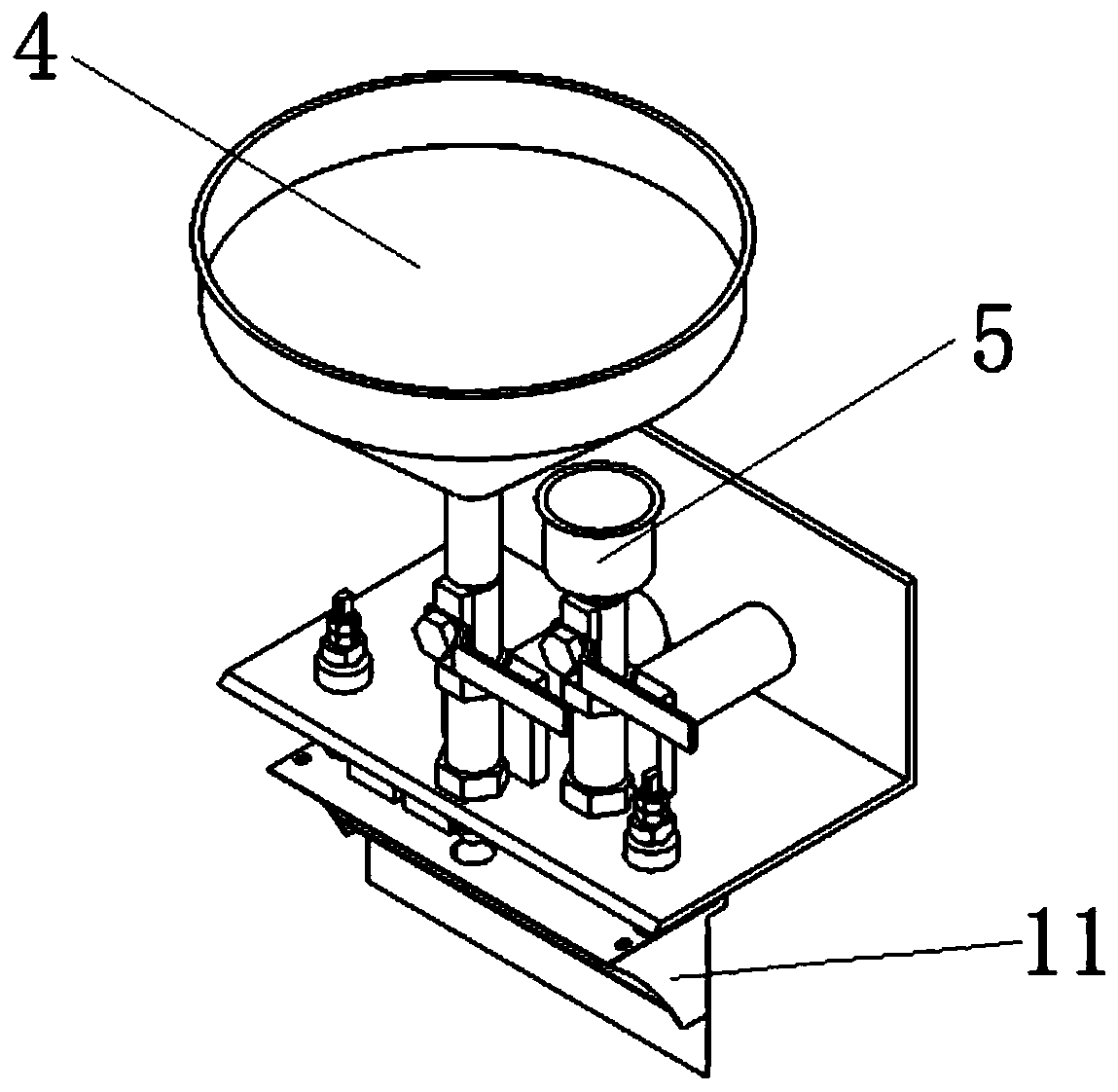

[0031] Specific implementation mode one: combine Figure 1-Figure 5 To illustrate the present embodiment, the present embodiment includes a frame 1, a drum 2, a heating device 3, a hopper 4, an oil hopper 5, a cutting device 6, a motor 7, a spatula 9, a coating tank 11 and a shaft 16;

[0032] The drum 2 is rotated on the shaft 16, and the shaft 16 is fixed on the frame 1. There is a heating device 3 inside the drum 2. The heating device 3 is fixedly connected with the shaft. The motor 7 drives the drum 2 to rotate through the first gear pair. The hopper 4 and the oil hopper 5 are fixed on the frame 1 respectively, the hopper 4 and the oil hopper 5 are respectively arranged above the drum 2 and correspond to the drum 2, the blade 9 is arranged on the discharge side of the drum 2, and the end of the blade 9 The cutting device 6 and the paint tank 11 are respectively fixed on the frame 1, the cutting device 6 is set on the same side as the blade 9, the paint tank 11 is set under...

specific Embodiment approach 2

[0036] Specific implementation mode two: combination Figure 4 To illustrate this embodiment, the heating device 3 of this embodiment includes a ceramic cylinder 3-1, a resistance wire, a temperature control switch and a high-temperature insulation terminal;

[0037] The ceramic cylinder 3-1 is fixed to the shaft 16, and the ceramic cylinder 3-1, the cylinder 2 and the shaft 16 are arranged concentrically, the cylinder 2 is set on the outside of the ceramic cylinder 3-1, and the outer surface of the ceramic cylinder 3-1 is provided with a spiral Slot 311, the resistance wire is wound and arranged in the spiral groove 311, the two ends of the resistance wire are connected with high-temperature insulation terminals, and the interface corresponding to the high-temperature insulation terminal and the resistance wire is connected to the power supply through a wire, and a temperature control switch is provided on the wire. The temperature measuring contact on the switch is fixed on ...

specific Embodiment approach 3

[0040] Specific implementation mode three: combination figure 2 To illustrate this embodiment, the blade 9 in this embodiment is lowered with an arc-shaped guide plate 10 , and the end of the arc-shaped guide plate 10 is disposed opposite to the cutting device 6 .

[0041] Such setting enables the pancakes produced by the spatula 9 to enter the cutting device 6 smoothly, which plays a good guiding role.

[0042] Other compositions and connections are the same as those in Embodiment 1 or Embodiment 2.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap