Electronically controlled skimmer

A skimmer and electric controller technology, applied in chemical instruments and methods, filtration separation, separation methods, etc., can solve the problems of low slag removal efficiency, low cleaning efficiency, and high labor intensity, and achieve safe and convenient operation and low operating costs. The effect of low and high slag collection rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

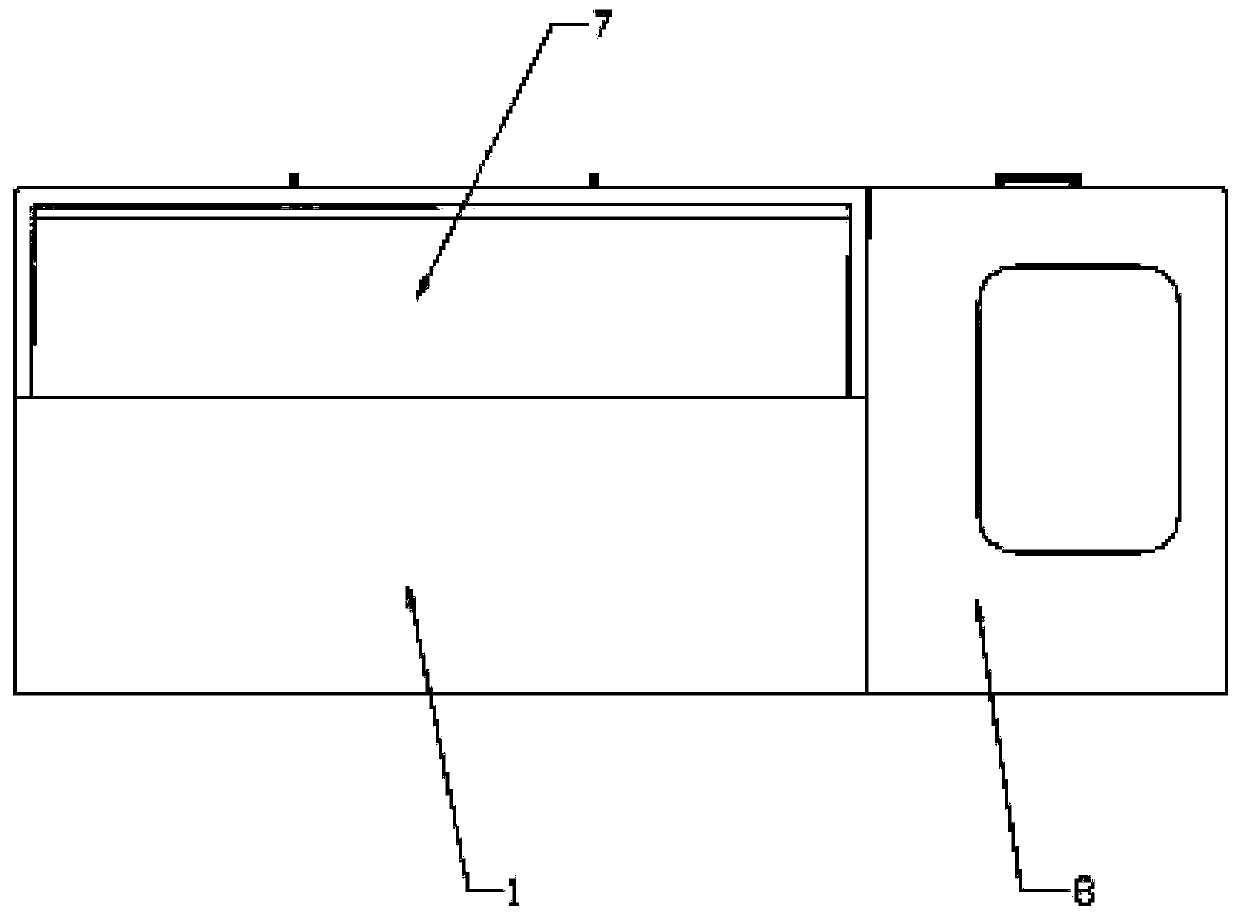

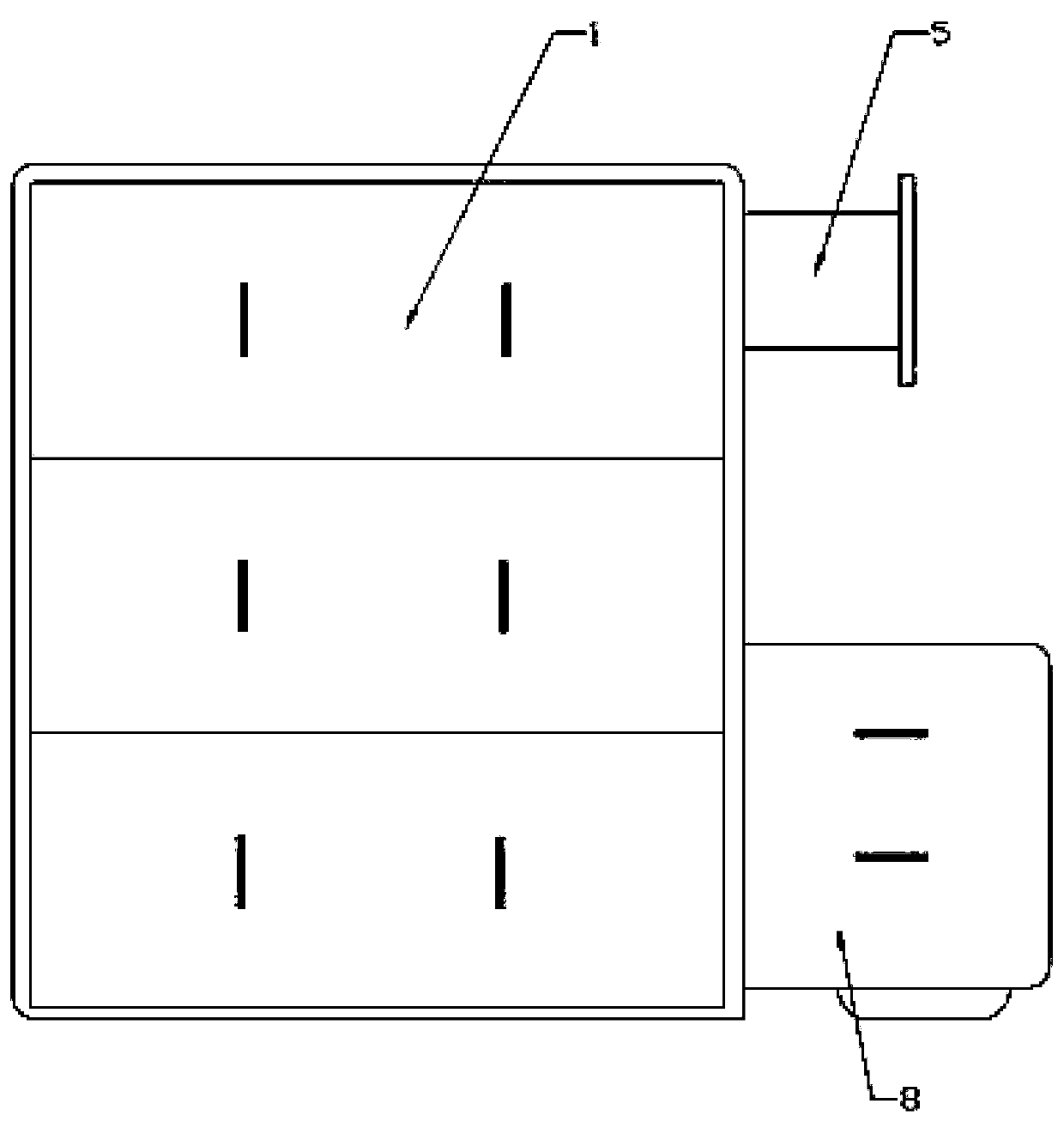

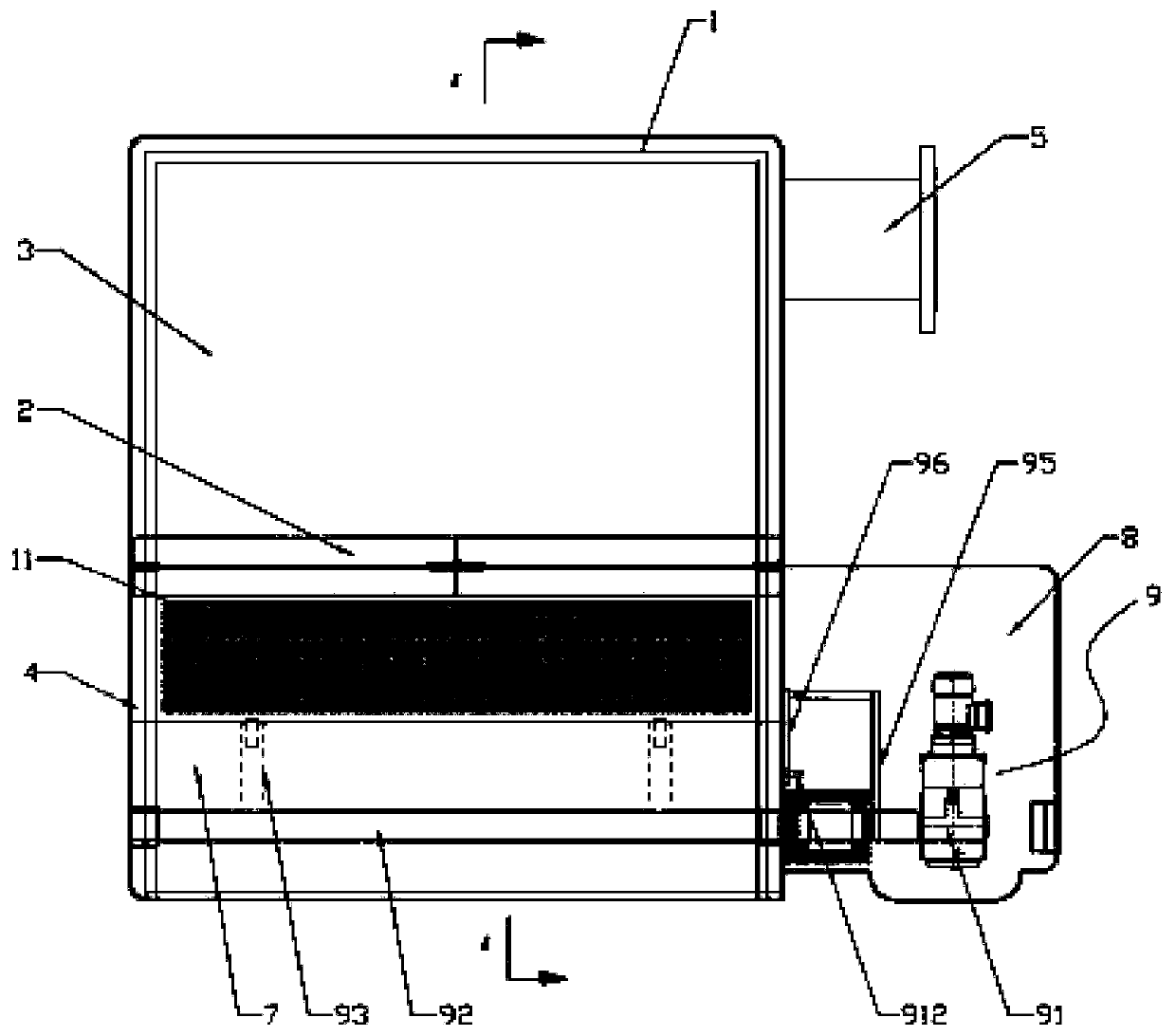

[0023] Such as Figure 1 to Figure 5 As shown, in this embodiment, the present invention includes a main box body 1, and a filter plate 2 is arranged inside the main box body 1, and two sides of the inside of the main box body 1 are welded to match the filter plate 2. The guide groove, the filter plate 2 is adapted to be inserted in the guide groove, this installation method makes the filter plate 2 separate the main box body 1 into a clean water storage tank 3 and a sedimentation tank 4, and the sedimentation tank 4 A scum collection basket 11 is installed, and the scum collection basket 11 is welded by a permeable orifice plate, the clear water storage tank 3 is provided with a drain pipe 5, the sedimentation tank 4 is provided with a water inlet 6, and the water inlet An adjustable slag-introducing water retaining plate 7 is obliquely installed at the nozzle 6, and a waterproof case 8 is provided at one end of the main box body 1, and a water-proof case 8 connected with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com