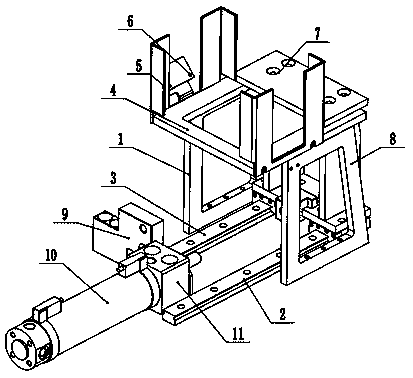

Three-laminating plate machining automatic feeding device

An automatic feeding and three-ply board technology, which is applied to feeding devices, wood processing equipment, manufacturing tools, etc., can solve problems such as low work efficiency, easy loosening of boards, and affecting work efficiency of sawing edges, so as to improve work efficiency and processing speed Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

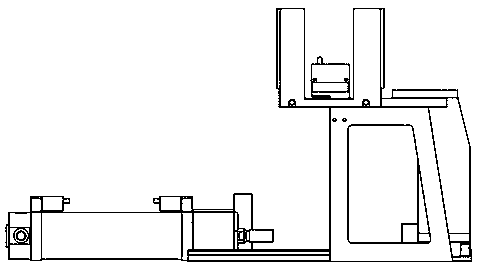

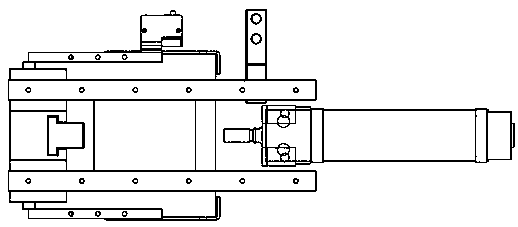

Method used

Image

Examples

Embodiment 2

[0031] Embodiment 2: a kind of self-unloading type plank feeder, when considering that plank 7 is unloaded to plank frame 8 from plywood support frame 1 in embodiment 1, if the plank 7 on the plank frame cannot be moved to other places in time, just Can cause the accumulation of plank 7 on plank frame 8, be unfavorable for the finishing of plank 7.

[0032] Therefore wooden pallet 8 has been improved. Plank frame 8 is changed into the mode of conveyer belt, is provided with bent plate chain 15 at both sides, and bent plate chain 15 is linked on the bent plate sprocket 16, and the middle of bent plate sprocket 16 passes and is provided with axle 18. One end of the wheel shaft 18 is connected with the motor through a bearing 19 .

[0033] Working process: when transferring the wooden board 7, the wooden board 7 is placed on the roller 6, and the angle iron piece 5 drives the roller 6 to rotate to transfer the wooden board 7 to the limit block 9 along the direction of the guide ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com