Method for regulating plant available heavy metals in municipal sludge composting

A heavy metal and sludge technology, applied in the preparation and application of sewage/sludge fertilizer, organic fertilizer, etc., can solve the problems of lack of targeted stabilization, endangering human health, etc., and reduce the content of heavy metals in plant-available state. , the effect of promoting reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] 1) Collect municipal sludge products at a depth of 20cm.

[0035] 2) Pretreatment: Vacuum dry the municipal sludge below -54°C until the moisture content is lower than 0.1%; then grind the municipal sludge to 100 mesh with an agate mortar, sieve and collect the municipal sludge powder, and use the same method to obtain straw powder.

[0036] 3) Take 10g of municipal sludge powder after pretreatment, soak the sludge powder with 10ml of 0.5mol / L HC1 for every 1g of sludge, wash the sample with pure water after standing for 10h, wash 3 times, and then freeze-dry, Detect carbon content and nitrogen content wherein with elemental analyzer, calculate carbon-nitrogen ratio to be 6.88;

[0037] Take 10 g of the pretreated straw powder, detect the carbon content and nitrogen content in it with an elemental analyzer, and calculate the carbon-nitrogen ratio to be 319.

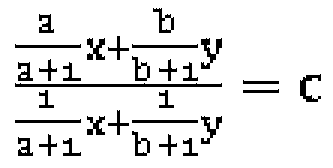

[0038] 4) According to the above calculation formula (I), bring in the carbon-nitrogen ratio of municipal slud...

Embodiment 2

[0041] Get the sludge obtained through step 3) in embodiment 1, according to the calculation formula (I) as mentioned above, bring into the carbon-nitrogen ratio of municipal sludge and stalks, calculate the carbon-nitrogen ratio of the mixed material, when mixed When the carbon-to-nitrogen ratio of the material is 8, sludge: straw = 0.856: 0.144 can be obtained in terms of mass. Take 0.856 tons of municipal sludge and 0.144 tons of straw, mix them, and compost them.

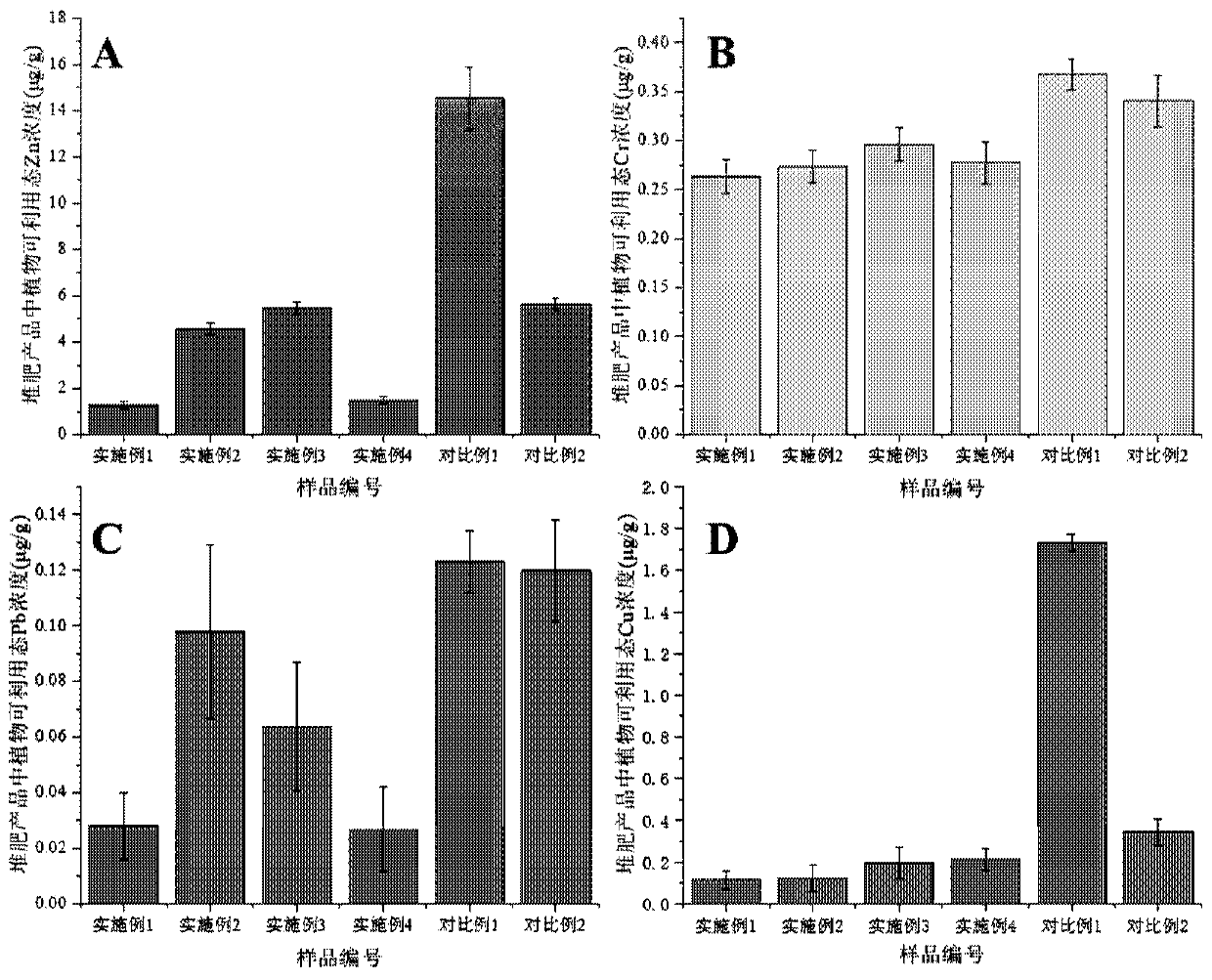

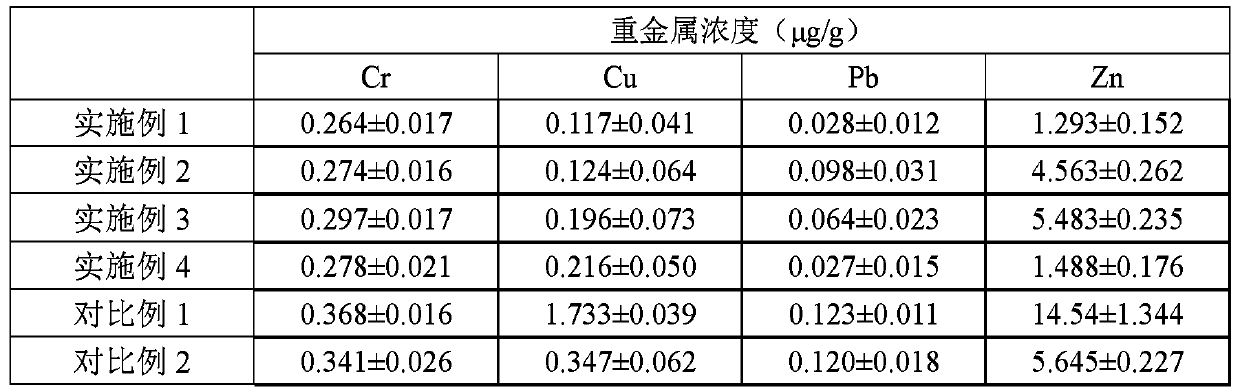

[0042] The same method used in step 5) of Example 1 was used to detect the plant-available heavy metal content in the compost product.

Embodiment 3

[0044] Get the sludge obtained through step 3) in embodiment 1, according to the calculation formula (I) as mentioned above, bring into the carbon-nitrogen ratio of municipal sludge and stalks, calculate the carbon-nitrogen ratio of the mixed material, when mixed When the carbon-to-nitrogen ratio of the material is 12, sludge: straw = 0.592: 0.408 can be obtained in terms of mass. Take 0.592 tons of municipal sludge and 0.408 tons of straw, mix them, and compost them.

[0045] The same method used in step 5) of Example 1 was used to detect the plant-available heavy metal content in the compost product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com