Passivator for heavy metal in farmland soil and preparation method thereof

A heavy metal passivator and soil technology, applied in chemical instruments and methods, soil conditioning materials, agriculture, etc., can solve the problems of ineffective soil remediation, uneconomical and reasonable treatment and maintenance costs, burning seedlings, etc., to prevent the spread of and occurrence, reduce absorption, improve soil fertility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

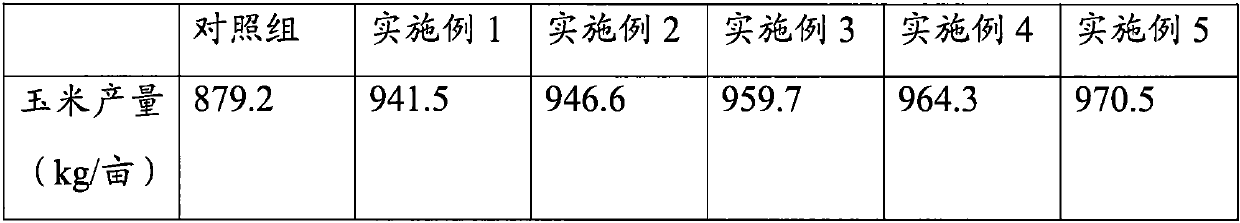

Examples

Embodiment 1

[0023] The raw materials of the heavy metal passivator for farmland soil: goethite 30kg, sepiolite 30kg, quicklime 25kg, silicate 15kg, phosphate rock powder 5kg, attapulgite 2kg, chitosan 2kg.

[0024] The preparation method of above-mentioned raw material is: (1) each raw material is weighed according to above-mentioned consumption, mix, standby;

[0025] (2) the material obtained in step (1) was calcined at 1100 ° C for 2 h, for subsequent use;

[0026] (3) The material obtained in step (2) was dried at 100° C. for 30 minutes, and ground to a particle size of 200 μm to obtain a heavy metal passivator for farmland soil.

Embodiment 2

[0028] The raw materials of the heavy metal passivator for farmland soil: goethite 40kg, zeolite 40kg, quicklime 35kg, silicate 18kg, phosphate rock powder 10kg, attapulgite 5kg, chitosan 6kg.

[0029] The preparation method of above-mentioned raw material is: (1) each raw material is weighed according to above-mentioned consumption, mix, standby;

[0030] (2) calcining the material obtained in step (1) at 1200° C. for 3h, for subsequent use;

[0031] (3) drying the material obtained in step (2) at 120° C. for 50 min, and grinding to a particle size of 300 μm to obtain a heavy metal passivator for farmland soil.

Embodiment 3

[0033] The raw materials of the heavy metal passivator for farmland soil: goethite 35kg, smectite 35kg, quicklime 28kg, silicate 16kg, phosphate rock powder 7kg, attapulgite 2kg, chitosan 2kg.

[0034] The preparation method of above-mentioned raw material is: (1) each raw material is weighed according to above-mentioned consumption, mix, standby;

[0035] (2) calcining the material obtained in step (1) at 1350° C. for 3h, for subsequent use;

[0036] (3) drying the material obtained in step (2) at 110° C. for 40 min, and grinding to a particle size of 250 μm to obtain a heavy metal passivator for farmland soil.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com