Pretreatment process of flame-retardant blackout fabric

A technology of shading cloth and mercerizing treatment, which is applied in the treatment of textile materials, continuous treatment of textile materials, fiber treatment, etc. It can solve the problems of poor flame retardancy and poor overall application effect, and achieve improved water solubility and good recombination. With synergistic effect, good leveling and softness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

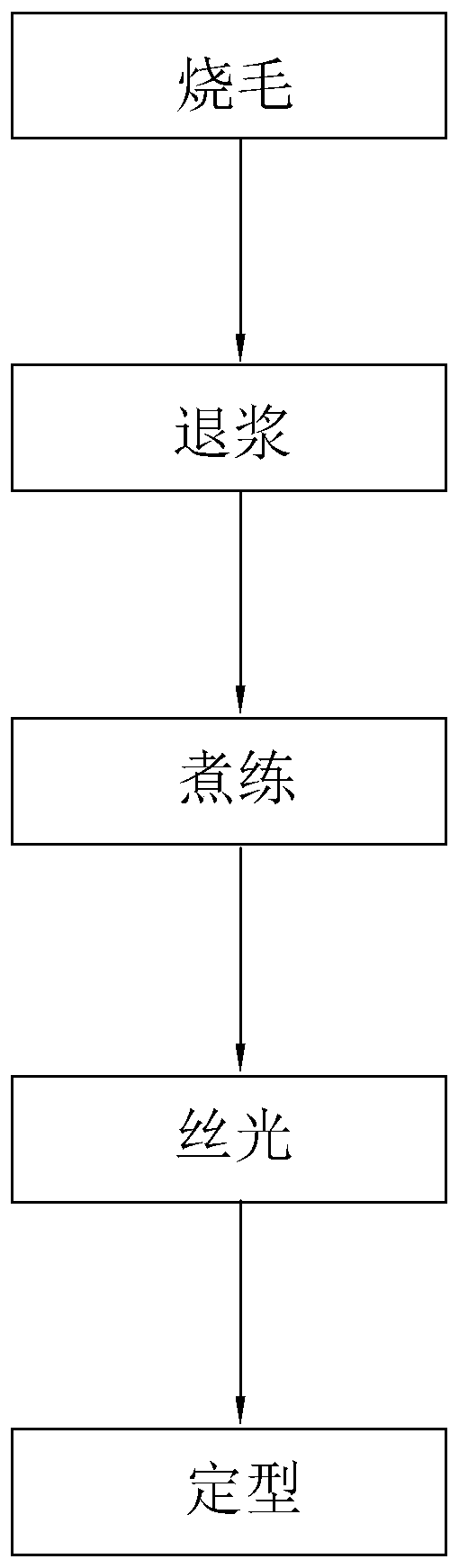

[0035] Example 1: A pretreatment process for flame-retardant shading cloth. The parts by weight of the chemical compositions of the scouring substances added during scouring are shown in Table 1, and are prepared through the following steps:

[0036] Step 1, singeing, the fabric is subjected to cylinder singeing treatment, the singeing speed is 95m / min, the burner temperature is 1150°C, and the temperature of the cold water drum is 55°C;

[0037] Step 2, desizing, desizing the fabric after the above-mentioned singeing treatment, the desizing temperature is 55°C, the desizing time is 1.5 hours, and the natural air drying time is 45 minutes;

[0038] Step 3, scouring, scouring the fabric after the desizing treatment, the temperature during the scouring process is controlled at 65°C, and the scouring time is 2 hours;

[0039] Step 4, mercerizing, performing mercerizing treatment on the fabric after the above-mentioned scouring treatment;

[0040] Step 5, setting the shape, perfo...

Embodiment 2-8

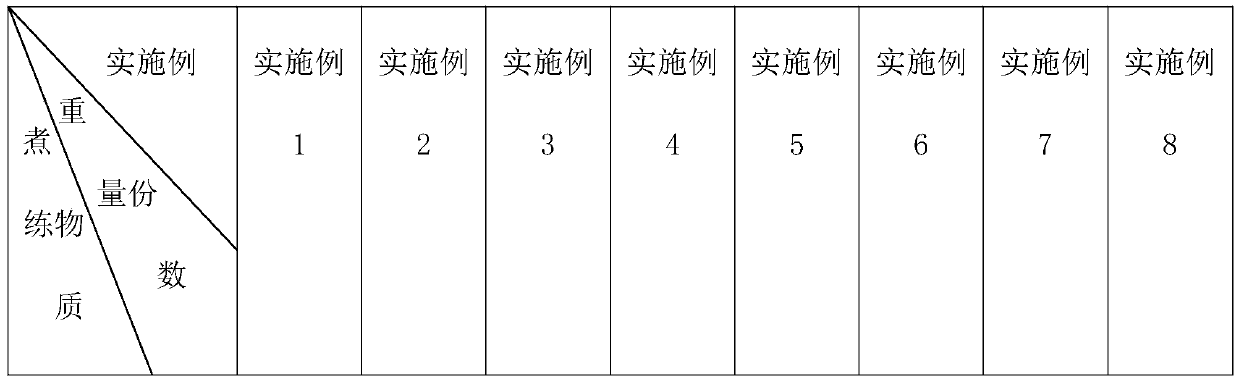

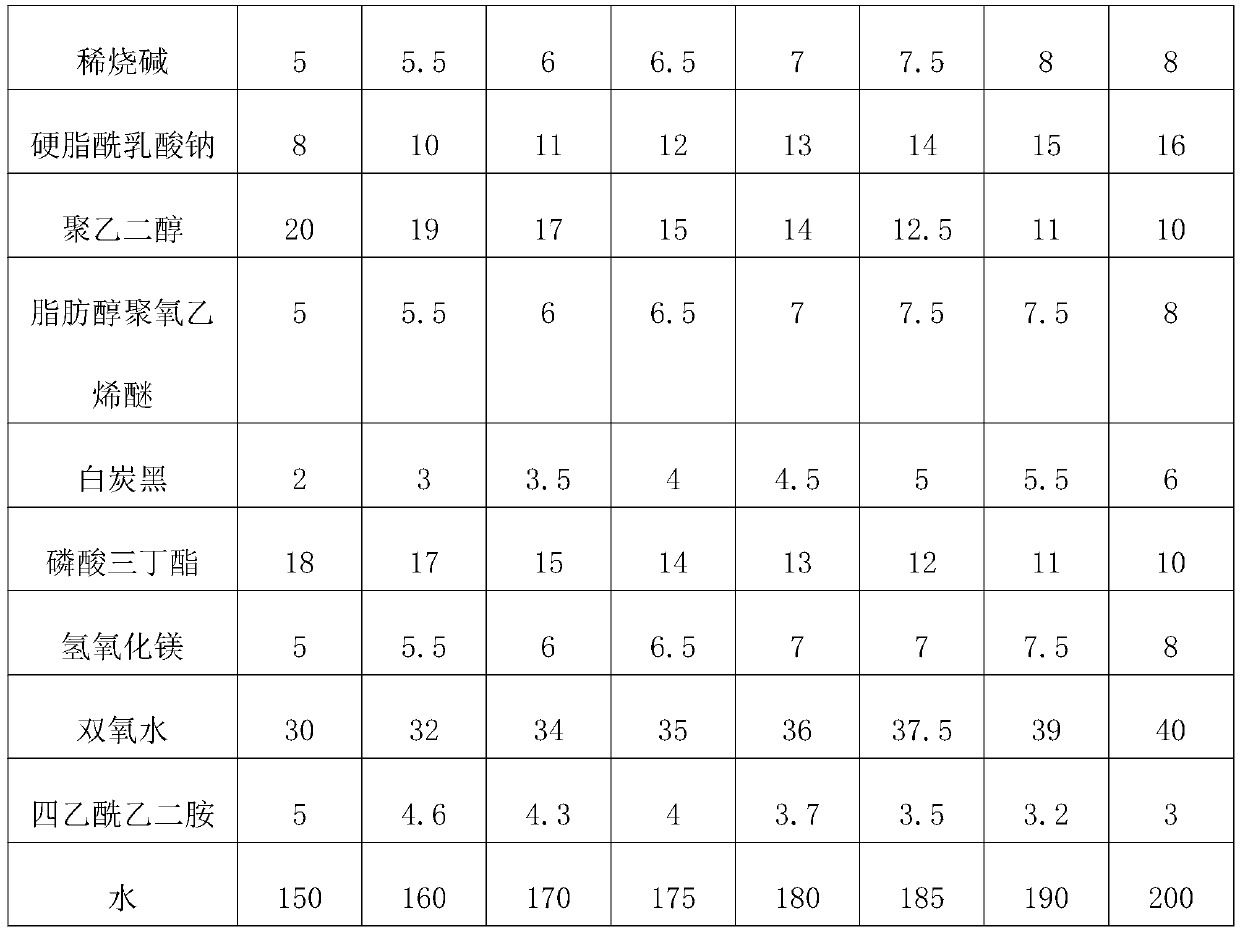

[0041]Example 2-8: A pretreatment process for a flame-retardant shade cloth. The difference from Example 1 is that the parts by weight of the chemical compositions of the scouring substances added during scouring are shown in Table 1.

[0042] Each component and parts by weight thereof in table 1 embodiment 1-8

[0043]

[0044]

Embodiment 9

[0045] Embodiment 9: A pretreatment process for a flame-retardant shading cloth. The difference from Embodiment 1 is that in step 3, 8 parts of sodium stearoyl lactylate added in scouring are replaced with sorbitol fat.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com