Direct injection gasoline engine intake control method and device

The technology of a gasoline engine and a control method is applied to a control device for improving the performance of an in-cylinder direct-injection gasoline engine, improving the performance of an in-cylinder direct-injection gasoline engine, and the field of air intake control, and can solve the problem of increased pump gas loss, harsh working environment, and gas. It can reduce the combustion fluctuation, improve the mixing process, and increase the flame propagation rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] In order to enable those skilled in the art to better understand the solution of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

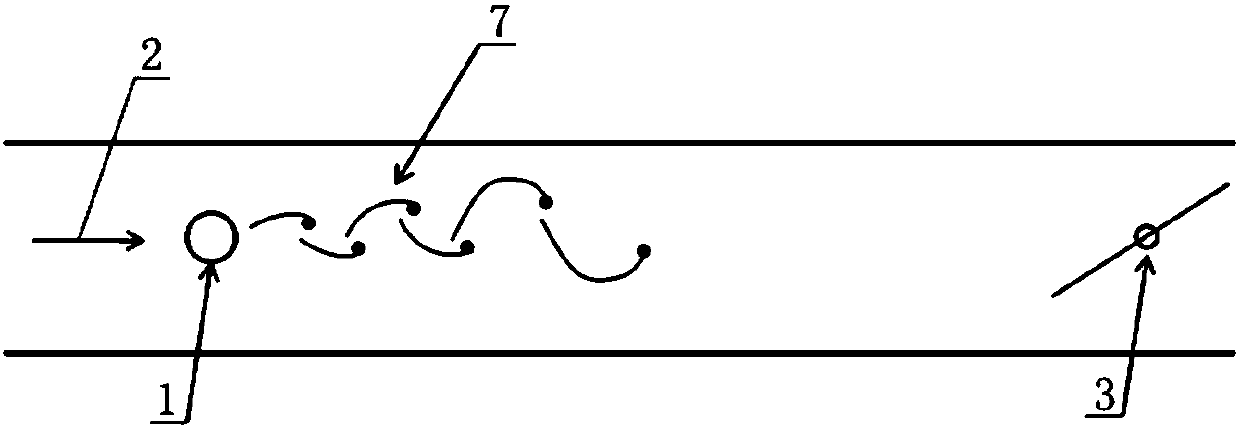

[0040] Aiming at the problems of low flow level in low-speed and low-load cylinders of in-cylinder direct-injection gasoline engines and high-speed and high-load fuel collisions, the present invention proposes a method that can improve in-cylinder airflow movement and increase in-cylinder turbulence level.

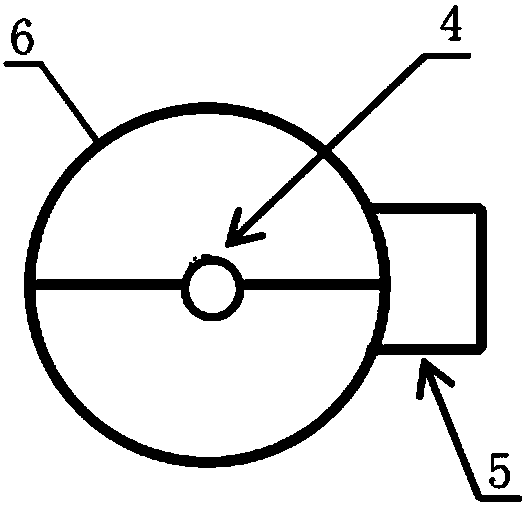

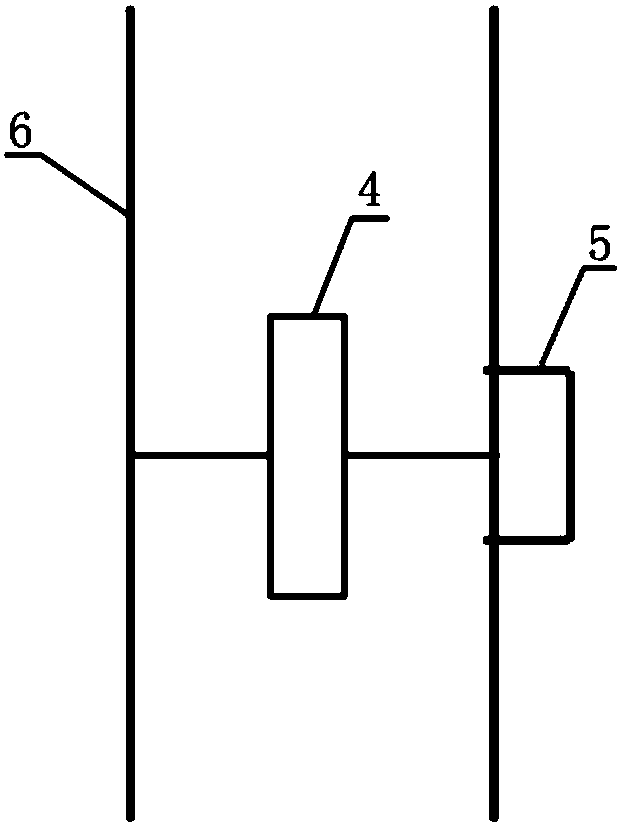

[0041] This method increases the turbulence level of the in-cylinder fluid by creating a Karman vortex street within the intake system, either at the air filter outlet (for non-supercharged engines) or at the hose-intercooler to the throttle inlet. A Karman vortex street generating device is installed on the air flow channel (for supercharged engines), so that the airflow forms a Karman vortex street in the intake pipe. With the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com