Grass trimmer carburetor pump cover

A technology for carburetors and lawn trimmers, which is applied in the direction of carburetors, machines/engines, mechanical equipment, etc., can solve the problems of increased processing equipment, increased production costs, and large differences in main structures, and achieves simple assembly, cost-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

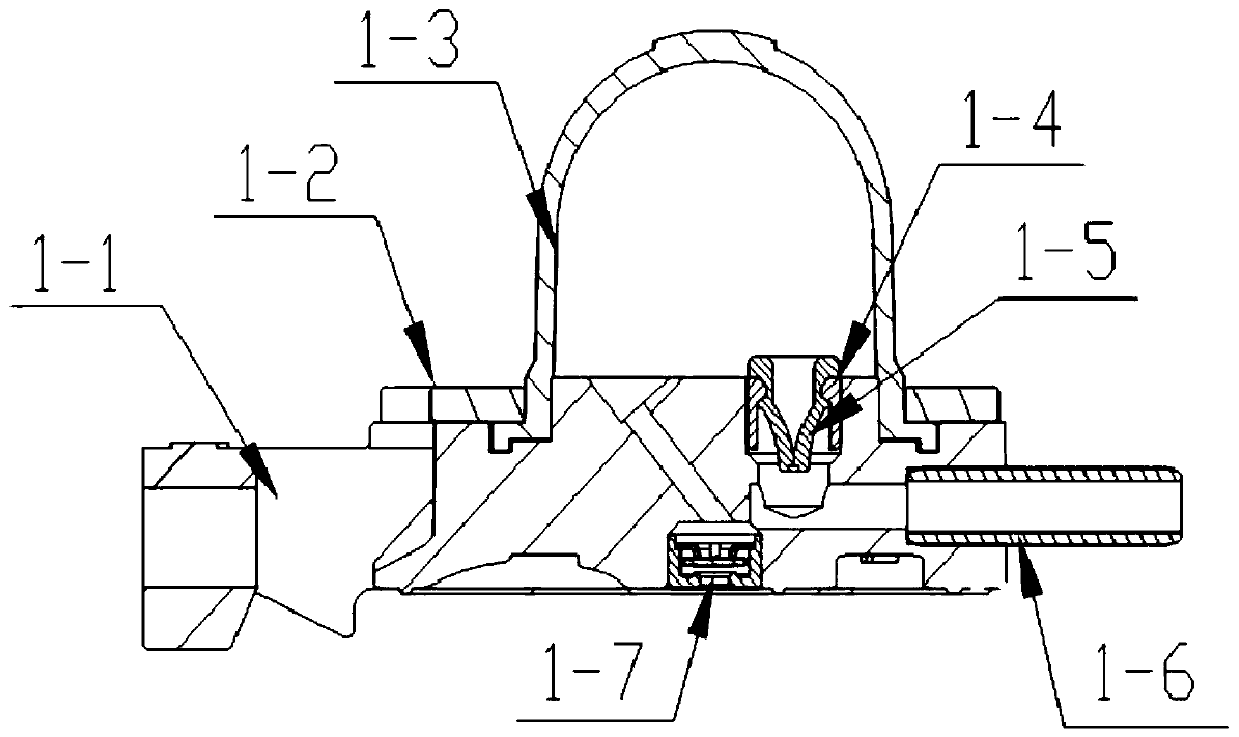

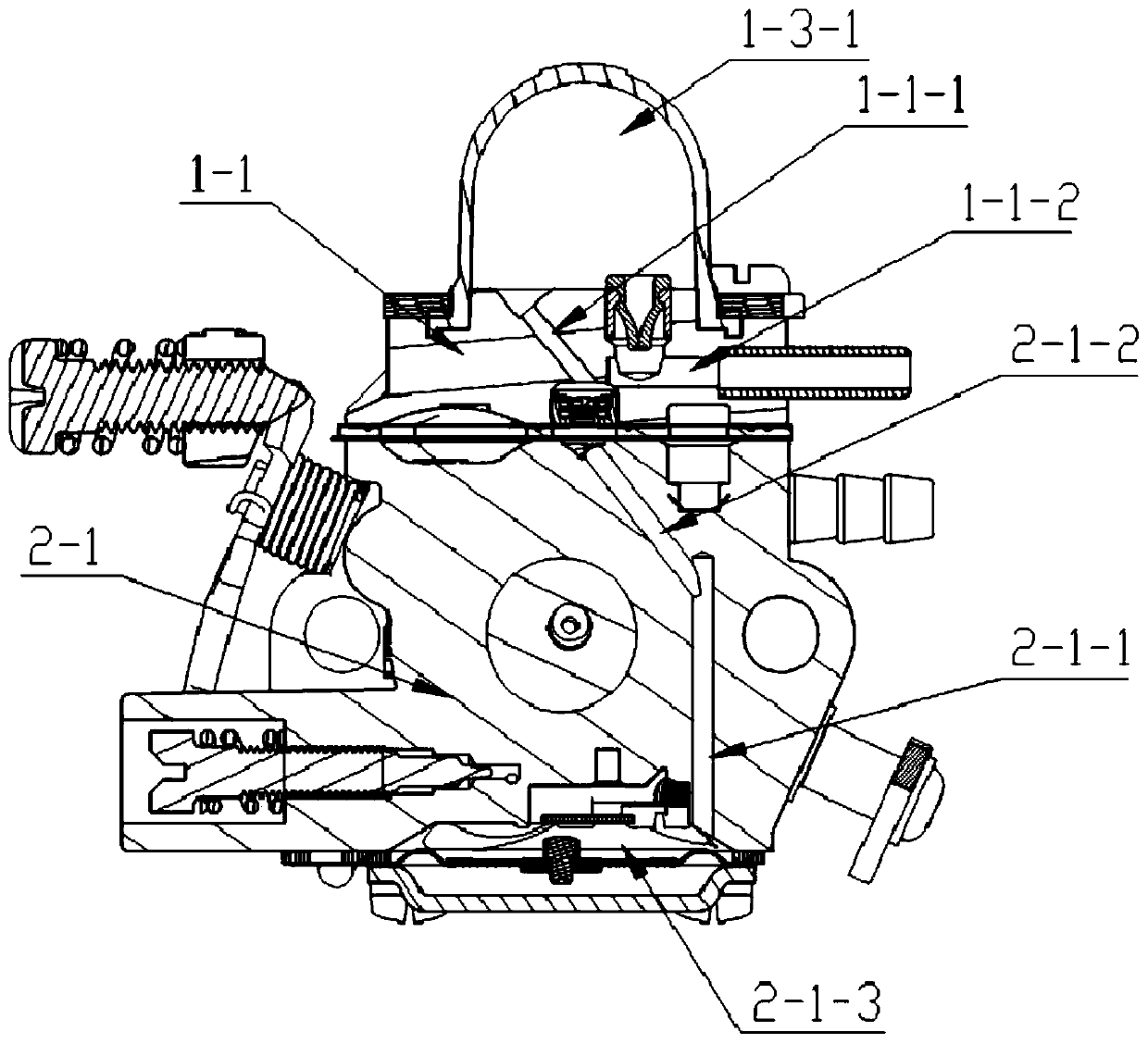

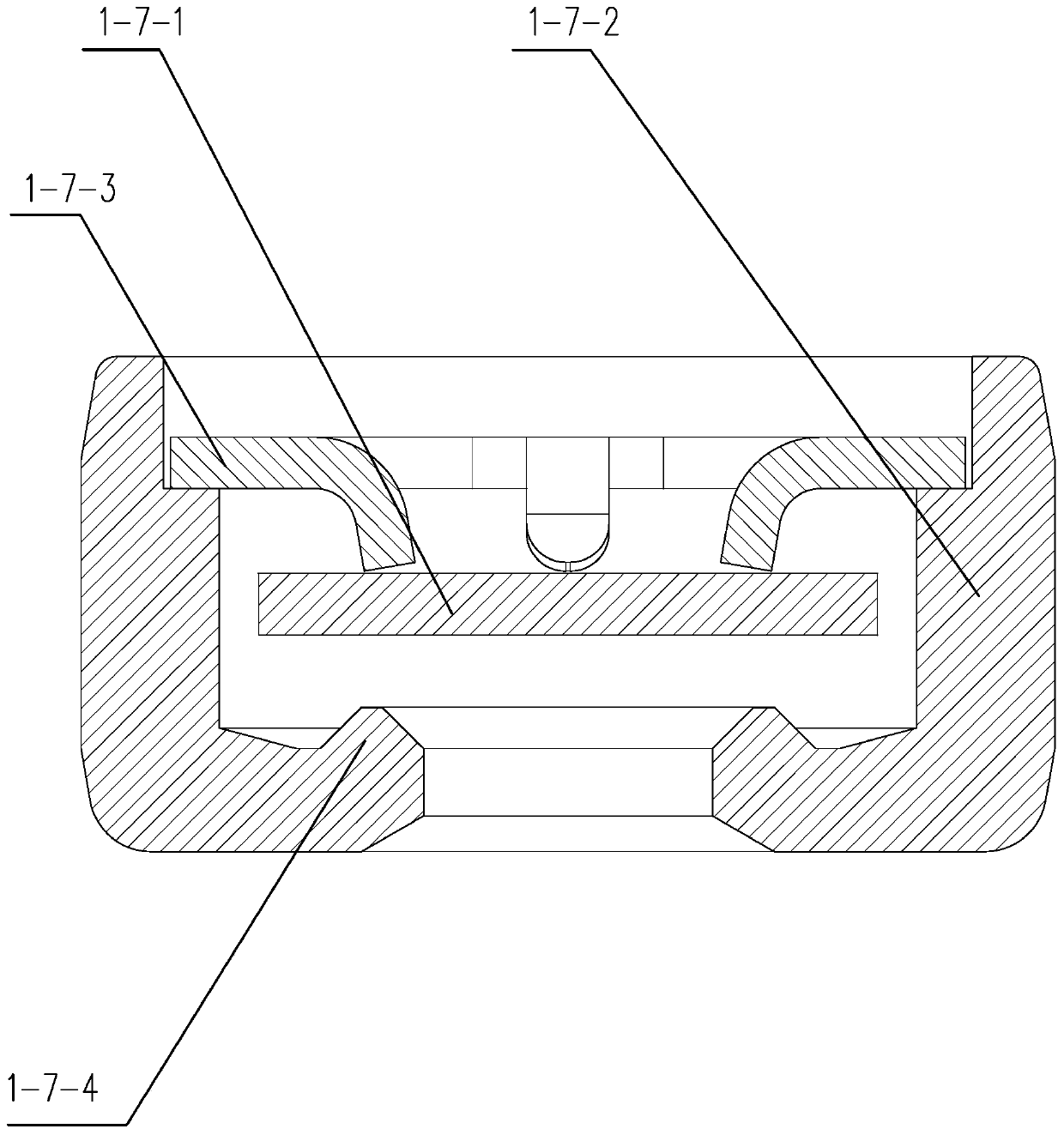

[0017] Depend on figure 1 , image 3 It can be seen that a pump cover of a carburetor for a mowing machine is disclosed, including a cover body 1-1, an oil bubble 1-3 is arranged on the cover body 1-1, and the oil bubble 1-3 and the cover body 1 -1 The end faces are combined to form a pressing cavity, the side wall of the cover 1-1 is provided with an oil return groove 1-6, and a first guide groove is formed in the pressing cavity, and the first guide groove guides the oil return groove 1-6 Pass, the first guide groove is provided with a one-way valve assembly to form a closure to the first guide groove, the one-way valve assembly includes a number of leaflets 1-5, and the first guide groove is provided with a copper sleeve 1 -4, one end of the leaflets 1-5 is provided with a card slot, and is fixedly connected to the copper sleeve 1-4 through the card slot, the other end is a free end and is set away from the pressing chamber, and the free ends of the adjacent leaflets 1-5 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com