Portable lamp mounting screw

A lamp installation and convenient technology, applied in the field of mechanical parts, can solve the problems of inconvenient disassembly, time-consuming and laborious, and achieve the effects of convenient disassembly, convenient operation and convenient production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

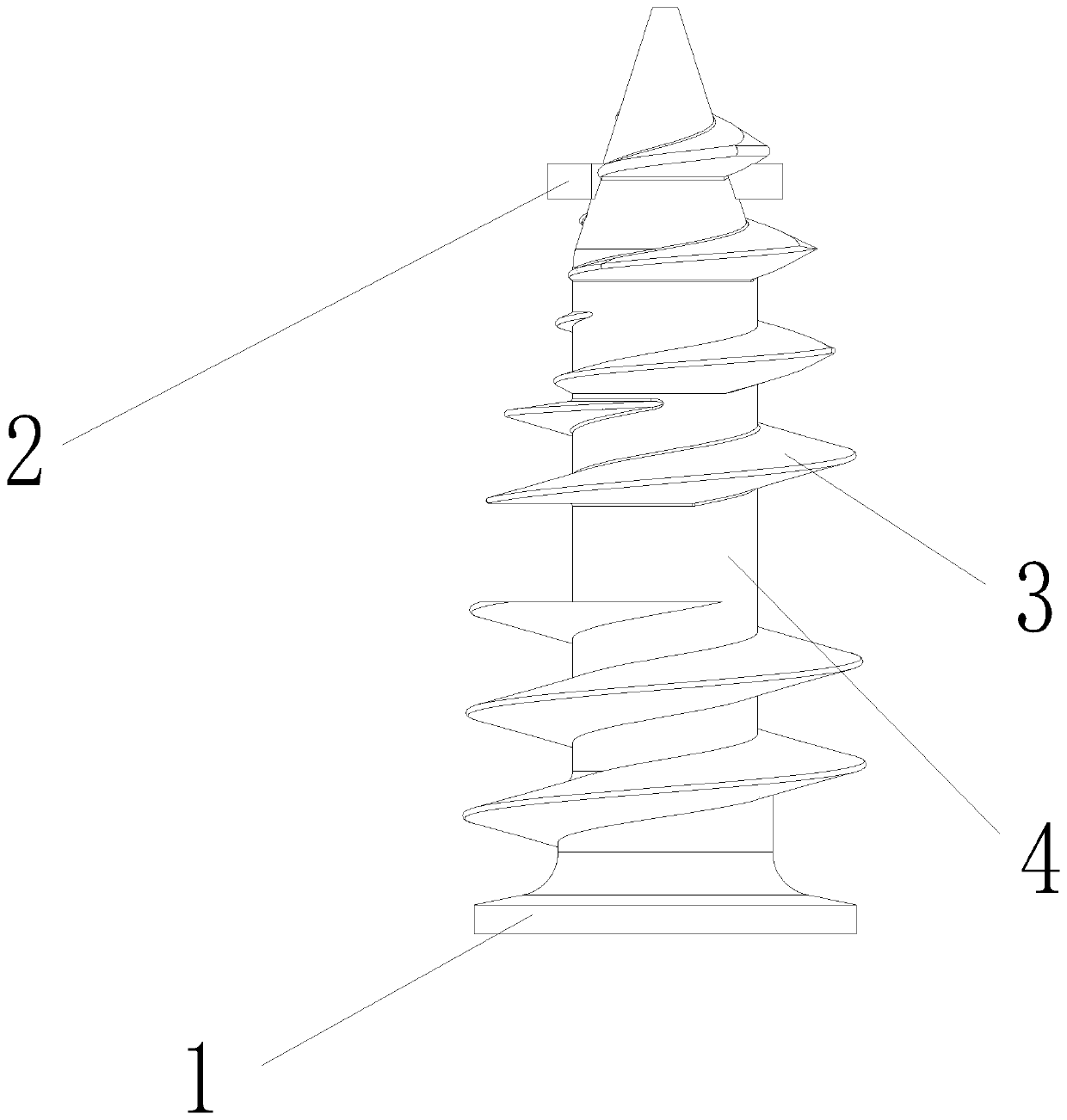

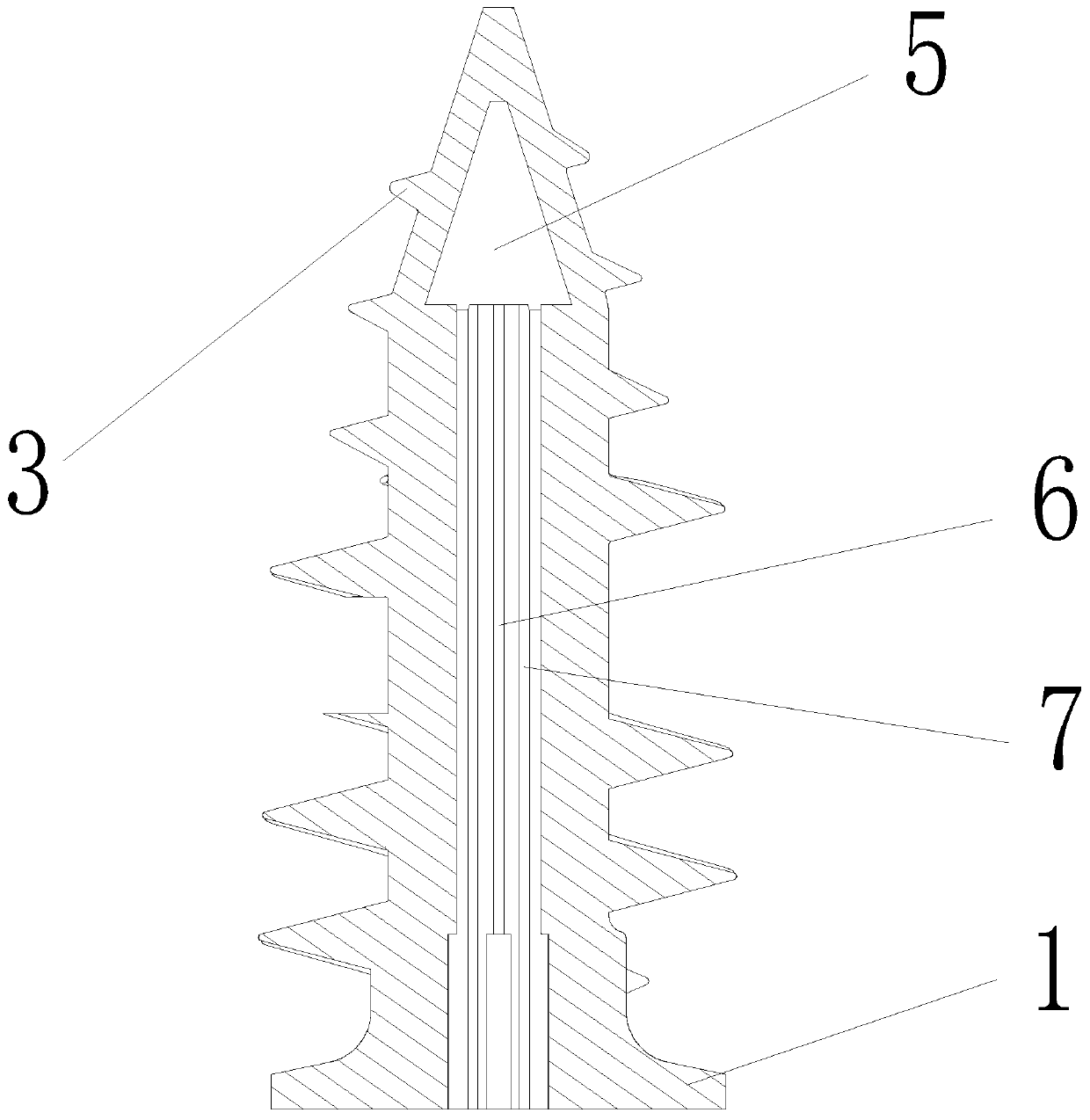

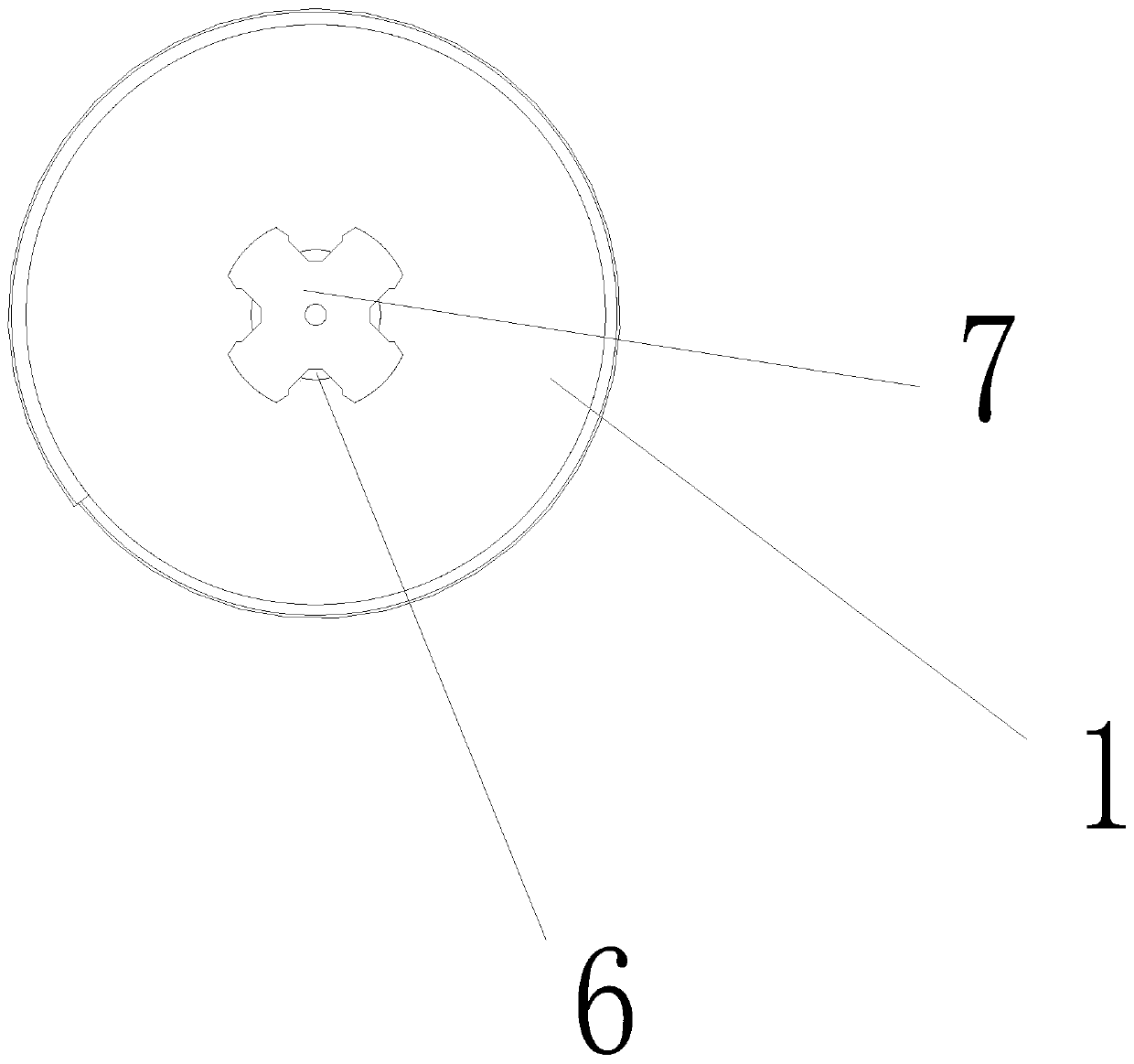

[0026] Such as figure 1 , 2 , 3, 4, 5, and 7, a portable lamp mounting screw includes an outer screw 16 and an inner screw 17, the outer screw 16 includes an outer screw 4, and one end of the outer screw 4 is provided with an outer screw head 1, and the outer screw 4 is provided with self-tapping thread 3, and the design of self-tapping thread 3 can make this screw break into plank 15 more easily, and is extremely firm, and the end of outer screw rod 4 away from outer screw head 1 is a sharp end, and the end of outer screw rod 4 is sharp. 4 is provided with a chip removal rib 2 near the sharp end, and the sharp end is arranged to facilitate external screws to be tapped into the plank 15, the chip removal rib 2 is in the shape of a strip, and the setting of the chip removal rib 2 can drill a hole in the plank 15, This hole can accommodate debris, and can also prevent the plank 15 from being cracked. If there is no chip removal rib 2, when the outer screw directly penetrates i...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap