Efficient weighing analytical balance and use method thereof

An analytical balance and high-efficiency technology, applied in the field of balances, can solve the problems of prolonged weighing time, large human factors, and inaccurate weighing, and achieve the effects of reducing labor intensity and workload, reducing ventilation area, and reducing weighing errors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

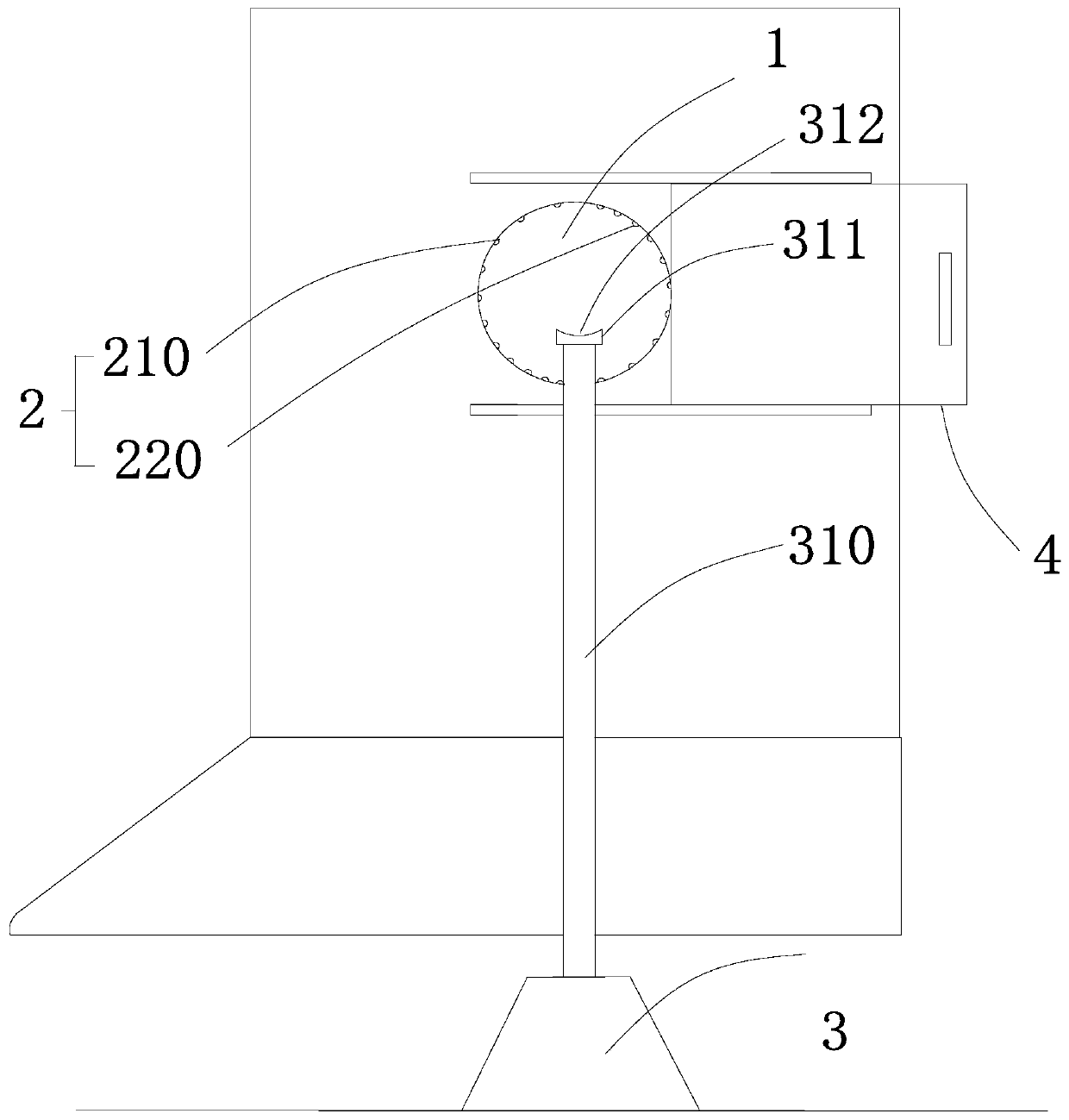

[0033] Such as figure 1 As shown, an analytical balance for high-efficiency weighing includes push-pull one side door or two side doors, and a window 1 is arranged on the middle and upper part of one side door of the analytical balance, and a plurality of strip-shaped or granular protrusions are arranged on the inner edge of the window. Protrusion 2; In this embodiment, the protrusions on the inner edge of the window are granular with a height of 0.5-2 mm, and the distance between the protrusions is not less than 0.5 mm.

[0034] An independent vibrator 3 is provided on the outside of the side door where the window is located. The vibrator is provided with a vertical vibrating rod 310, and the upper end of the vibrating rod is horizontally provided with a pallet 311; the pallet is facing the window. As a peripheral device, the vibrator can be selectively set according to specific conditions.

[0035] The protrusions on the inner edge of the window are evenly distributed and h...

Embodiment 2

[0043] A method for using an analytical balance for efficient weighing, comprising the steps of:

[0044] 1) Close the doors of the analytical balance, reset the analytical balance to zero, and insert the weighing spoon containing the sample or reagent from the window into the analytical balance for weighing;

[0045] 2) When weighing to the end, touch the handle of the weighing spoon to the inner edge of the window, and slide the handle of the weighing spoon along the inner edge of the window, and the weighing spoon will vibrate to shake off the medicine or reagent in the weighing spoon ;

[0046]Alternatively, the handle of the weighing spoon is brought into contact with the stand to trigger the vibrator, and the vibrating rod vibrates, driving the weighing spoon to vibrate to shake off the medicine or reagent in the weighing spoon. The vibrator can evenly shake off the sample or reagent in the weighing spoon bit by bit, making the weighing more accurate and efficient; and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Amplitude | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap